Hydrogen-oxygen oxygen-rich preburner of full flow staged combustion cycle engine

A pre-combustion chamber, oxygen-enriched technology, applied in machines/engines, rocket engine devices, mechanical equipment, etc., can solve problems such as high cost, high difficulty, and large oxygen ratio, and achieve the benefits of combustion and flame, improve reliability, The effect of improving gas uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

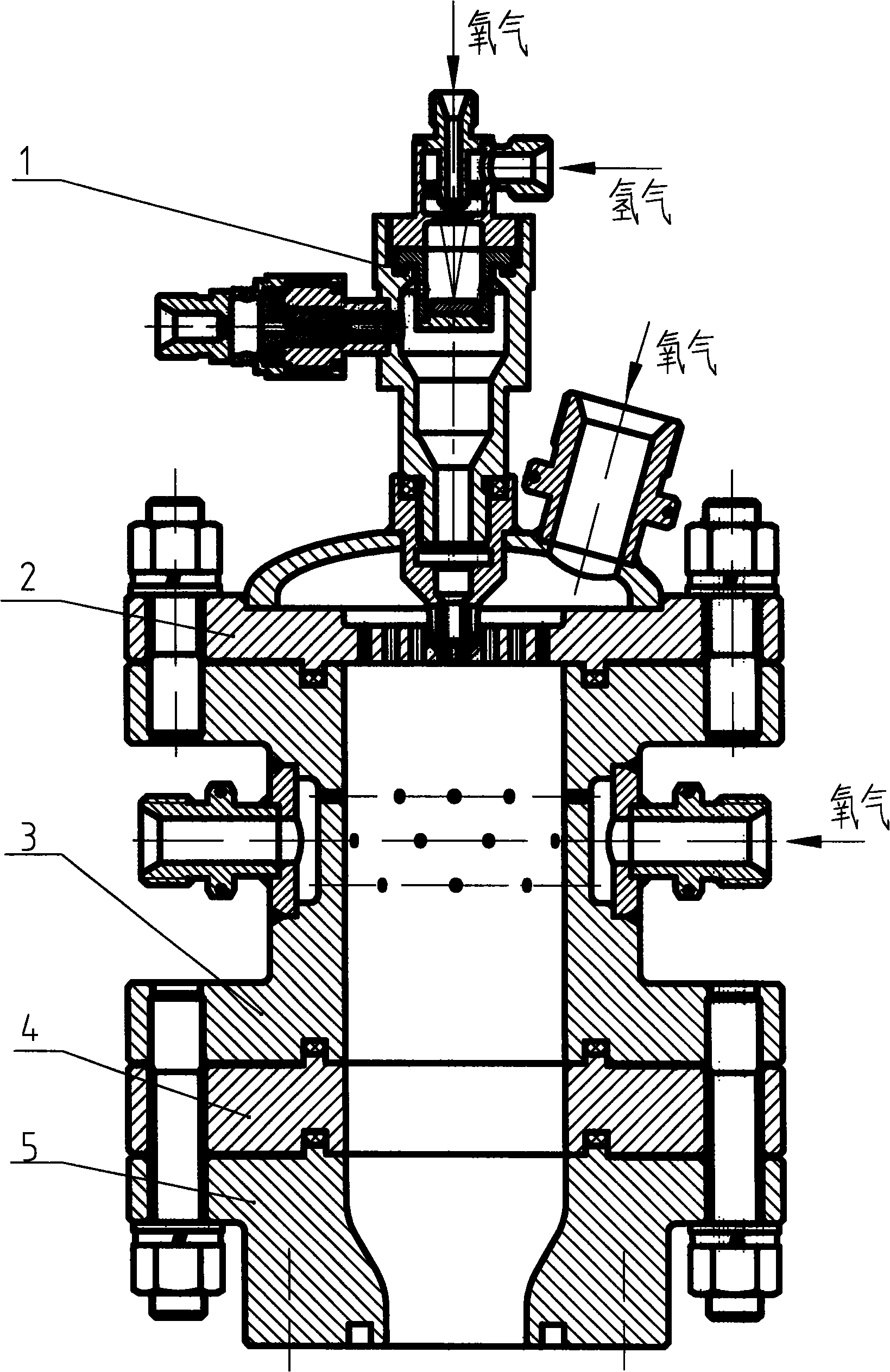

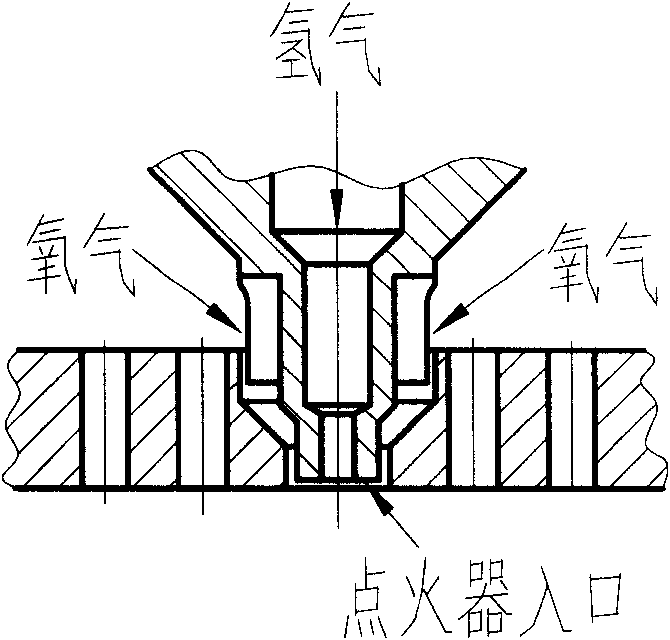

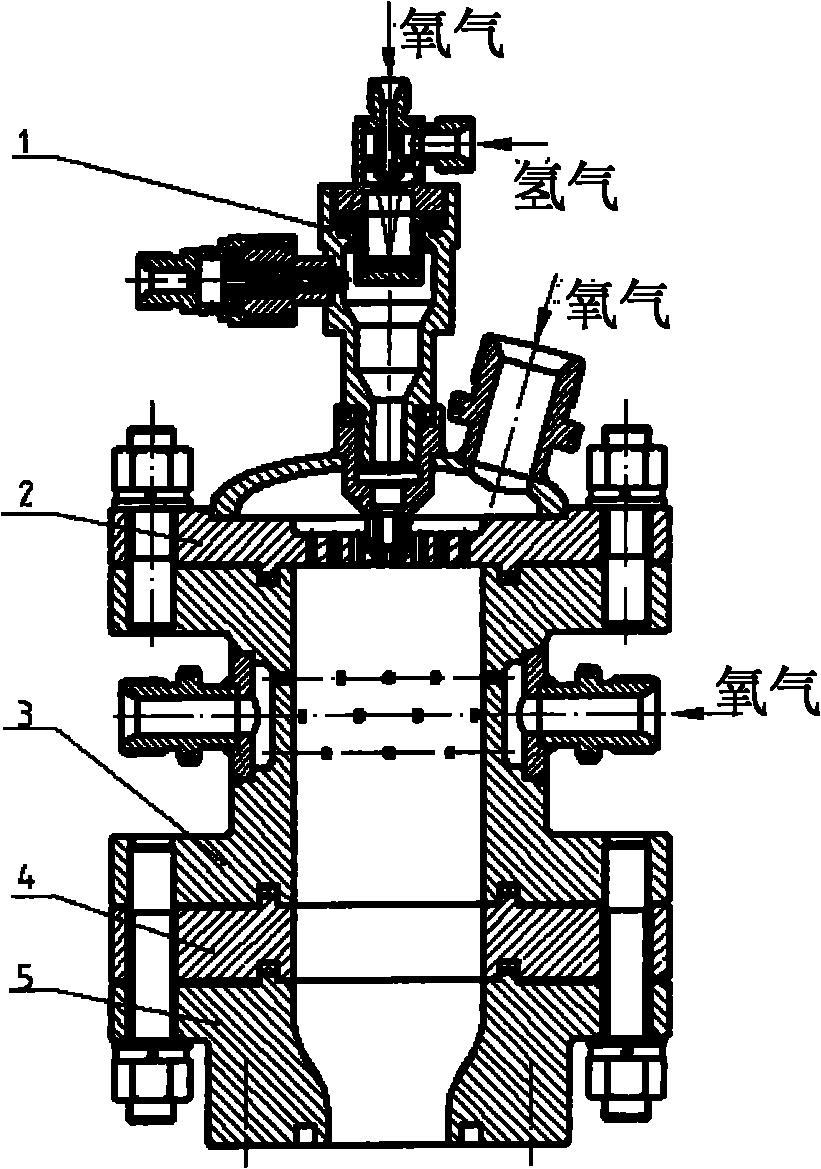

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] The pneumatic resonant igniter 1 is connected with the head 2 of the oxygen-enriched pre-combustion chamber through threads, and the position of the inlet of the igniter is the center of the injection panel of the head. The combustion gas of the igniter is hydrogen and oxygen. During the test, the hydrogen and oxygen are ignited through the air resonance heating resonance tube and then enter the oxygen-enriched pre-combustion chamber for ignition. Hydrogen and oxygen are introduced from the oxygen-enriched pre-chamber supply line.

[0011] After the ignition process, the oxygen supply to the igniter is turned off, the hydrogen circuit is maintained, and the igniter is converted into a hydrogen injector. Since all the hydrogen enters the oxygen-enriched pre-combustion chamber from the outlet of the igniter, the mixing ratio in the central area is reduced, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com