Three- impeller axial flow fan of subway traction motor brake cooling system

A traction motor and cooling system technology, applied in machines/engines, axial flow pumps, mechanical equipment, etc., can solve the problems of dynamic coordination, affecting fan efficiency, and high noise, reducing wind resistance coefficient, improving efficiency, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

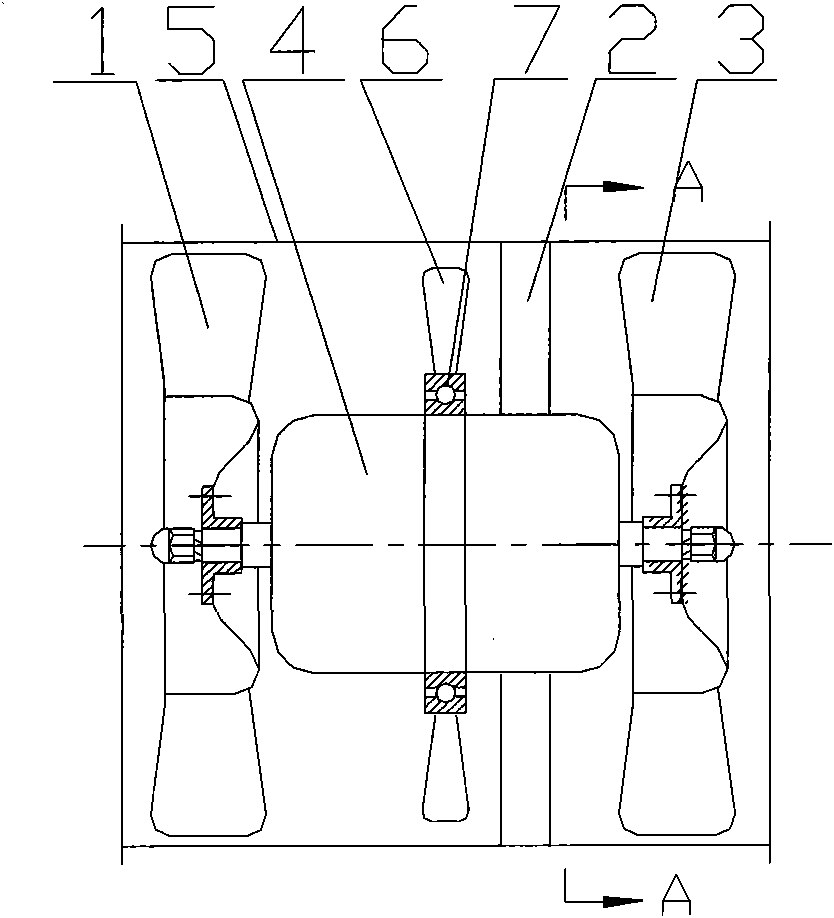

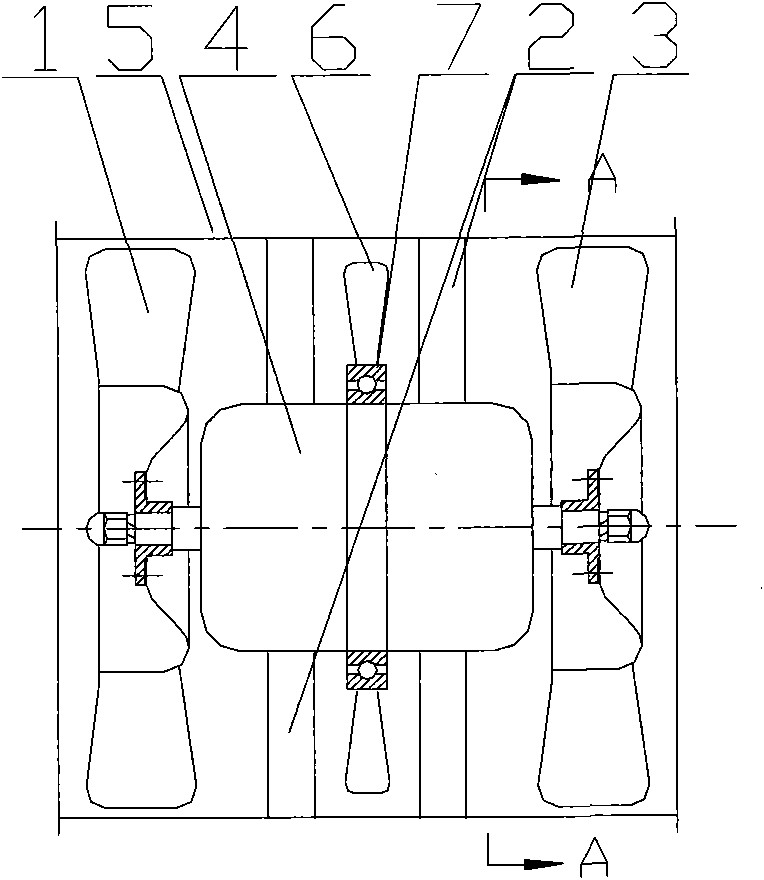

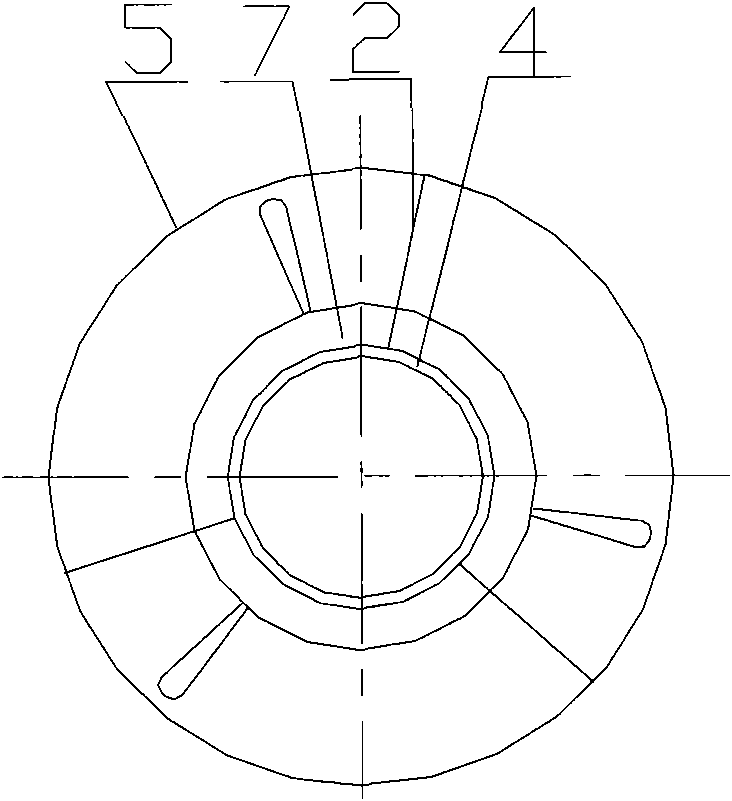

[0012] Embodiment 2: with reference to attached figure 2 . On the basis of Example 1, three streamlined deflectors 2 are used on both sides of the impeller 6 to fix the motor 4 in the axial flow fan casing 5, that is, the six streamlined deflectors 2 are divided into two groups, respectively located at The two sides of the impeller 6 and the motor 4 are fixed in the axial flow fan housing 5 .

Embodiment 3

[0013] Embodiment 3: On the basis of Embodiment 1, the air-cooling method of the three-blade axial flow fan in the brake cooling system of the subway traction motor, the air volume generated by the rotation of the front impeller 1 on the coaxial motor 4 in the three-blade axial flow fan passes through The impeller 6 leads to the rear impeller 3 and is led out by the rear impeller 3 .

Embodiment 4

[0014] Embodiment 4: On the basis of Embodiment 3, the air volume generated by the rotation of the front impeller 1 on the coaxial motor 4 in the three-blade axial flow fan is rectified and guided to the impeller 6 through the streamlined deflector 2 and guided through the impeller 6 To the rear impeller 3, and derived from the rear impeller 3.

[0015] Embodiment 4: On the basis of Embodiments 2 and 3, the air volume generated by the rotation of the front impeller 1 on the coaxial motor 4 in the three-blade axial flow fan is rectified and guided to the impeller 6 through the streamlined deflector 2, and then passed through After the secondary rectification of the streamlined deflector 2 , the flow is guided to the rear impeller 3 and is led out by the rear impeller 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com