Fiber Bragg grating strain sensor

A technology of strain sensor and fiber grating, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of large-scale structural network monitoring that cannot be long-distance, complex structure, complex shielding packaging, etc., to improve strain monitoring performance , Eliminate electromagnetic interference and ensure the effect of monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] An embodiment of the present invention provides a fiber grating strain sensor, which can realize online strain monitoring in large-scale low-temperature projects, effectively eliminate the influence of electromagnetic interference in complex and harsh environments, ensure reliable monitoring data, and improve strain monitoring performance.

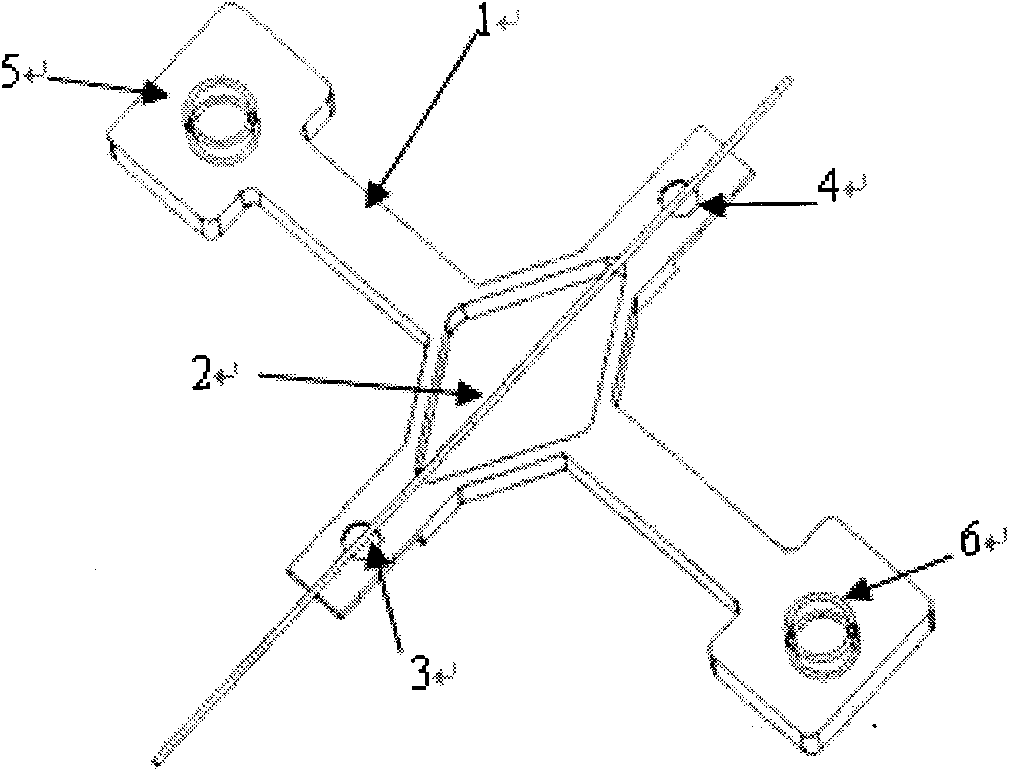

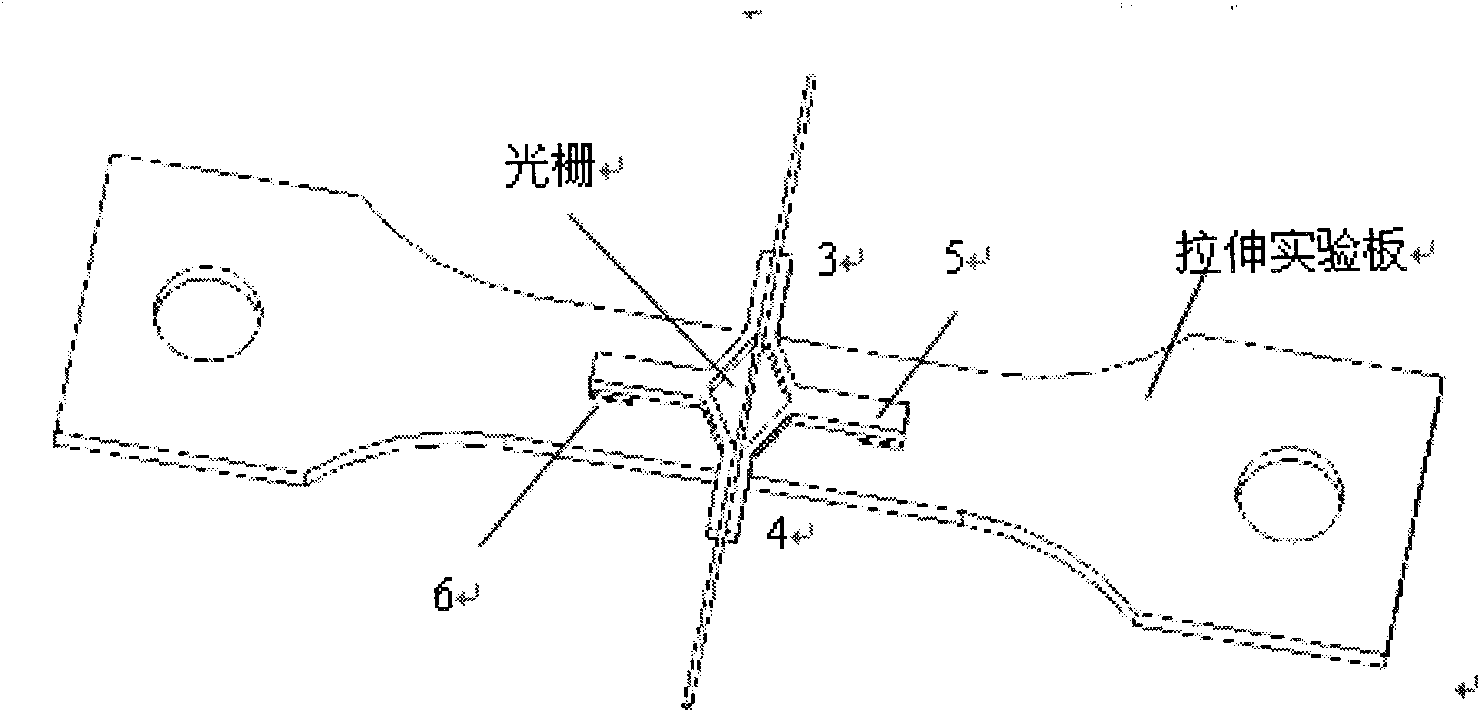

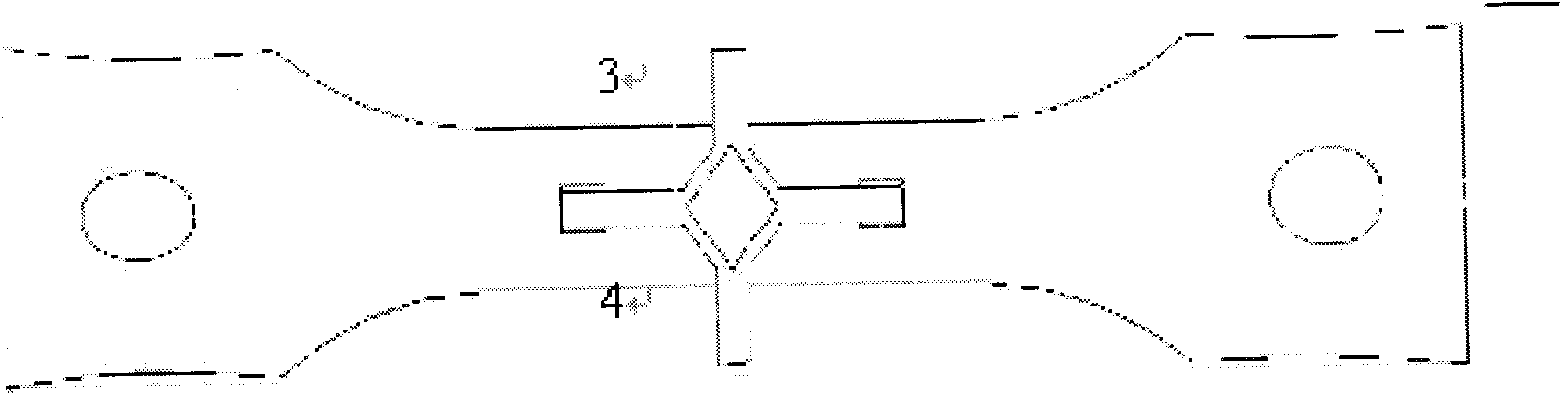

[0021] In order to better describe the embodiment of the present invention, the specific implementation manner of the present invention will be described in conjunction with the accompanying drawings, as follows figure 1 Shown is a schematic structural view of the fiber grating strain sensor provided by the embodiment of the present invention, figure 1 Including: rhombic strain base 1 and fiber Bragg grating 2, wherein:

[0022] The two ends of the grid area of the fiber grating 2 are respectively fixed on one axis of the rhombic strained base 1. figure 1 The two ends of the gate region of the fiber grating 2 are fixed on 3 and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com