Regulatable Hall effect sensor

A Hall-effect sensor technology, applied in adjustable Hall-effect sensor, automotive cam and crankshaft speed/position detection field, can solve the problems of unadjustable switch point, narrow range of use, prone to malfunction, etc. Vibration performance, a wide range of applications, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

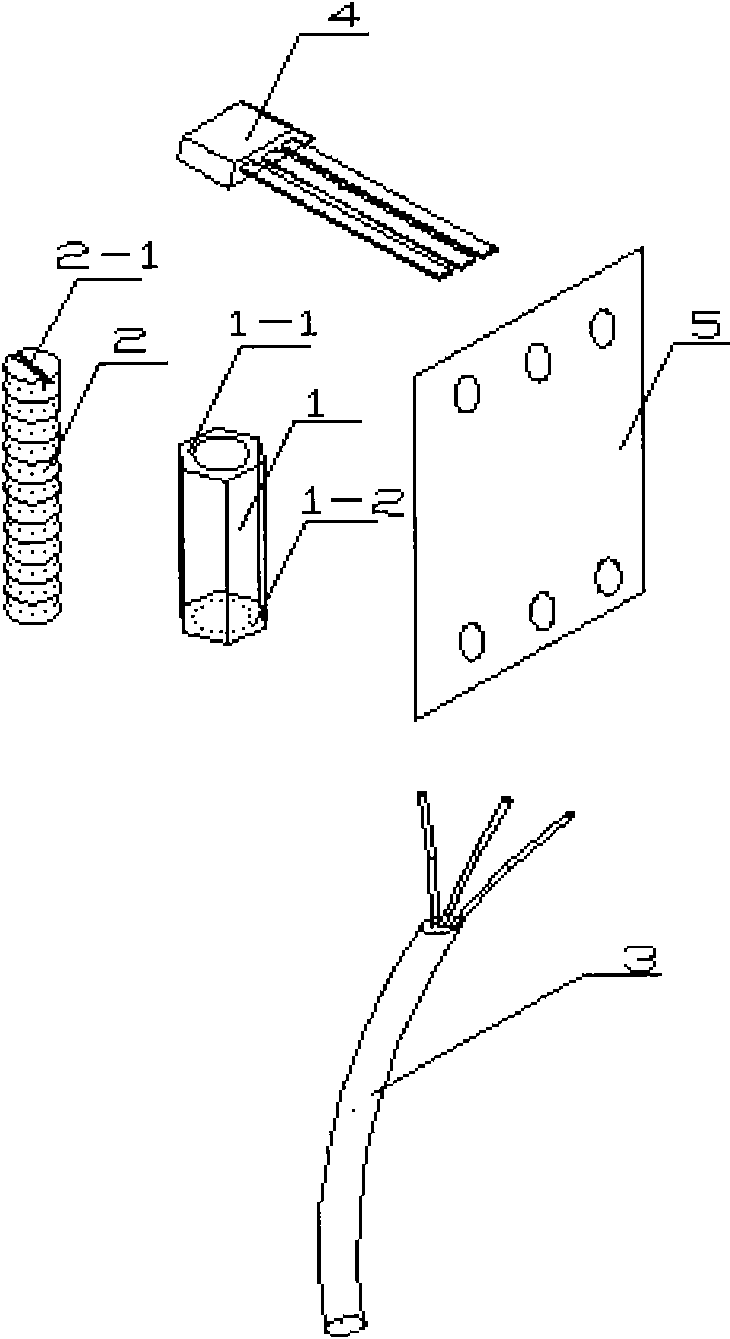

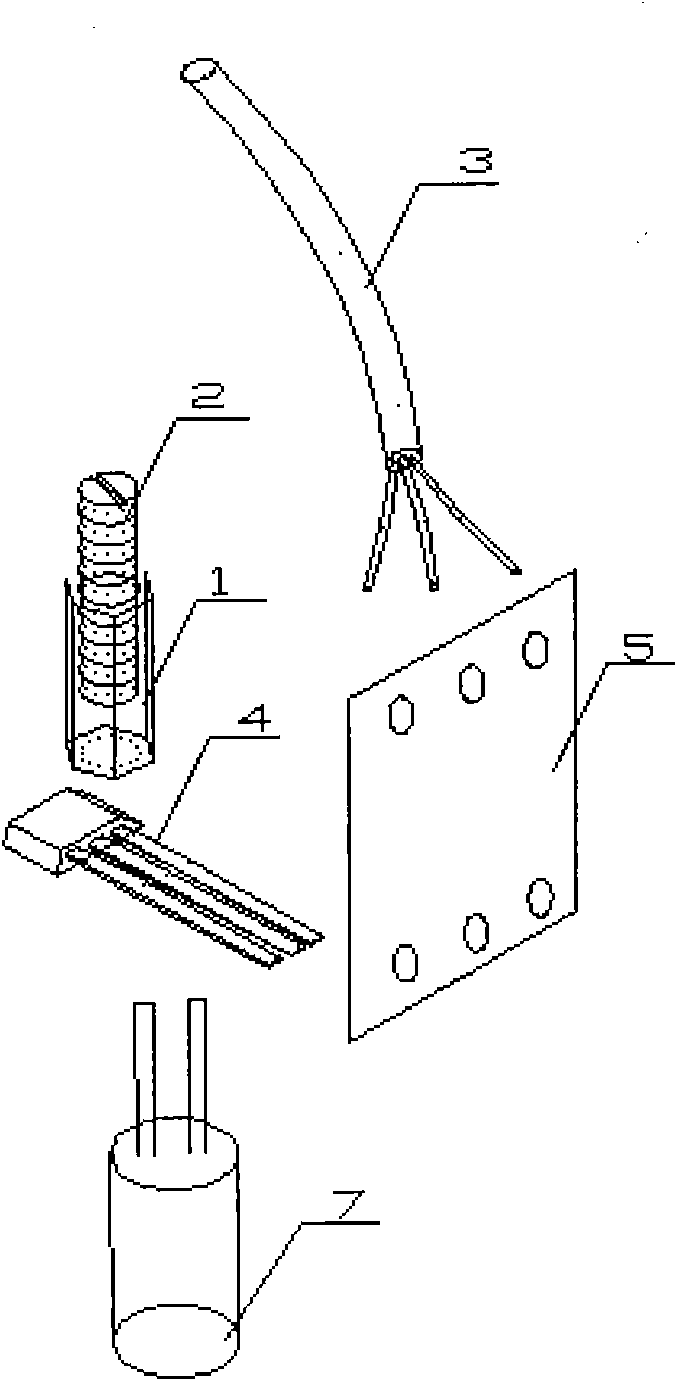

[0021] Such as figure 1 As shown, this embodiment is composed of lead wire group 3, printed circuit board 5, Hall element 4, magnetic steel sleeve 1, and magnetic steel 2. The magnetic steel 2 is a cylindrical permanent magnet, which is arranged on the outer surface of the magnetic steel 2. There are external threads, and a groove 2-1 is provided on the upper surface of the magnetic steel 2. The magnetic steel sleeve 1 is made of copper without magnetism. The magnetic steel sleeve 1 is hollow, and the hollow part is provided with internal threads. The internal thread and the magnetic steel 2 external threads cooperate with each other. The magnetic steel 2 is installed in the magnetic steel cover 1, and the groove 2-1 faces upward. The magnetic steel cover 1, the lead wire group 3 and the Hall element 4 are all welded on the printed circuit board 5, and the lower bottom surface 1-2 of the magnetic steel cover 1 and the Hall element 4 are close to each other.

[0022] As a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com