Half-bridge drive circuit chip

A circuit chip and half-bridge drive technology, which is applied in the direction of circuits, electrical components, and electric solid-state devices, can solve the problems of large space occupation, long distance, and high cost, and achieve the effects of small space occupation, reduced production costs, and compact chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

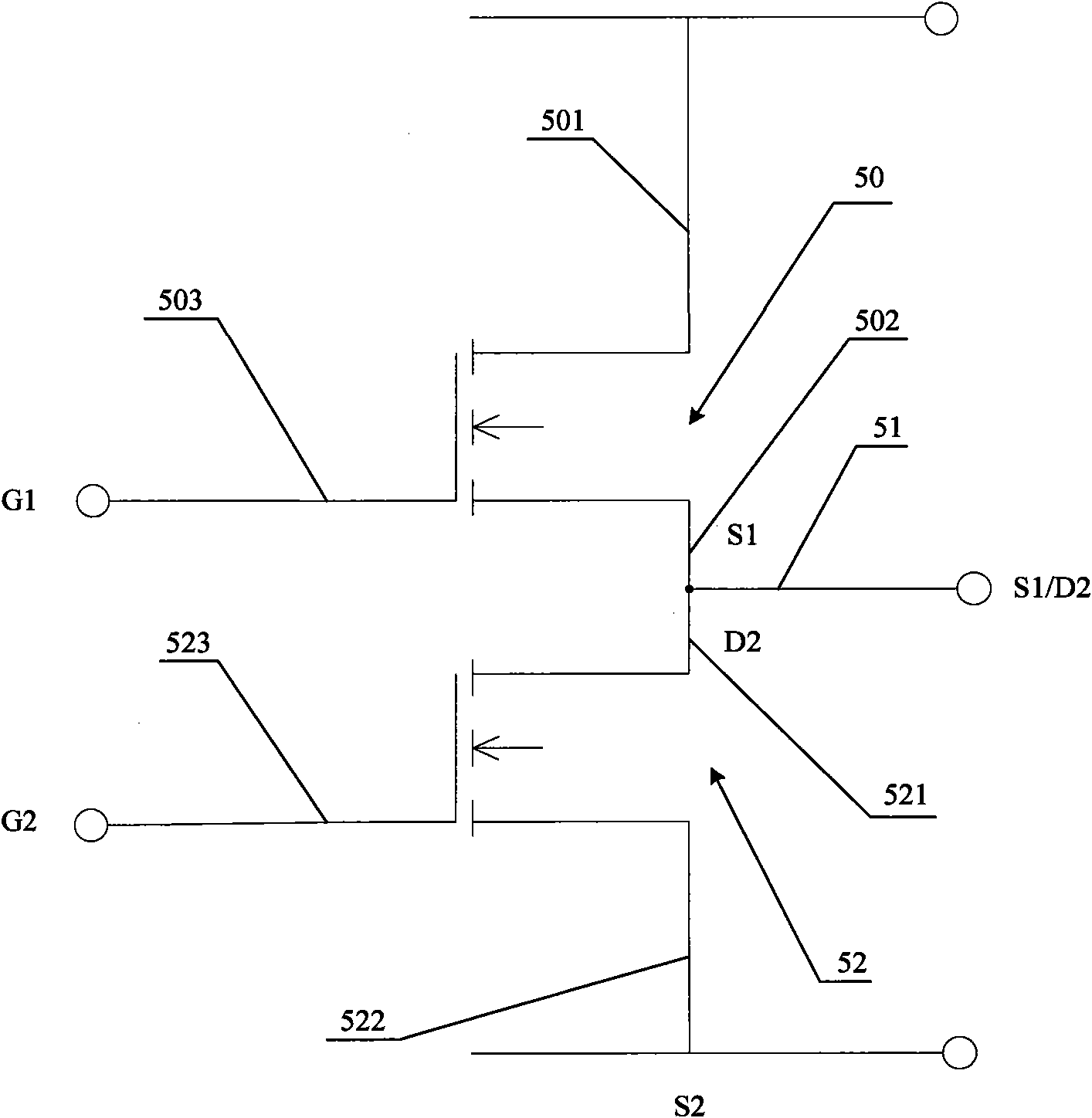

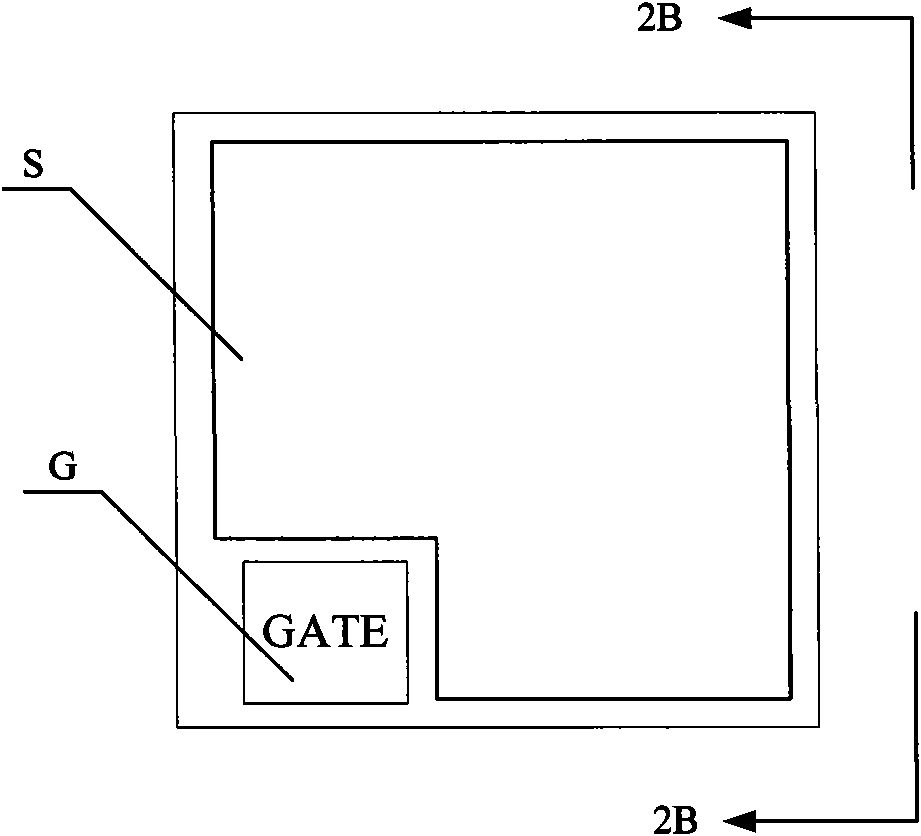

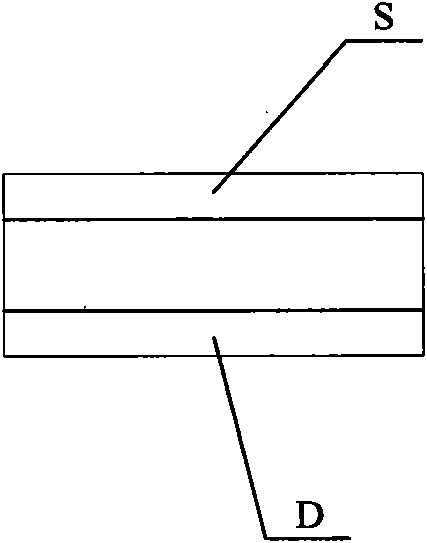

[0018] Such as image 3 As shown, a kind of half-bridge driving circuit chip that the present invention proposes, it comprises the lead frame 9 of DIP-8 (in-line eight-pin integration), and lead frame 9 has a packaging surface 91, is provided with eight mutually on the packaging surface 91. Isolated and insulated pins are the 1st pin, the 2nd pin, the 3rd pin, the 4th pin, the 5th pin, the 6th pin, the 7th pin and the 8th pin, package There are also three base islands 21, 22, 23 which are isolated and insulated from each other on the surface 91. The three base islands 21, 22, 23 are not connected to the eight pins, and each of the three base islands 21, 22, 23 has a One connecting pin, the base island 21 has a connecting pin 211, the base island 22 has a connecting pin 221, the base island 23 has a connecting pin 231, the three connecting pins 211, 221, 231 are independent of each other, and the connecting pin 211 is connected to the sixth pin , the connecting pin 221 is conn...

Embodiment 2

[0023] Such as Figure 4 As shown, in this embodiment, a SOIC-14 (Small Outline Integrated Circuit Package, Small Outline Integrated Circuit Package) lead frame 9 is used, and fourteen mutually isolated and insulated leads are arranged on the package surface 91 of the lead frame 9. The pins are the 1st pin, the 2nd pin, the 3rd pin, the 4th pin, the 5th pin, the 6th pin, the 7th pin, the 8th pin, the 9th pin, the 8th pin The 10th pin, the 11th pin, the 12th pin, the 13th pin, and the 14th pin, and three base islands 21, 22, 23 that are isolated and insulated from each other are arranged on the package surface 11, and the three base islands 21 . The six connecting pins 215, 216, 225, 226, 235, 236 are independent of each other, the connecting pin 215 is connected with the sixth pin, the connecting pin 216 is connected with the eleventh pin, and the sixth pin and the eleventh pin are connected through The base islands 21 are electrically connected to each other, the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com