Radiation curable inkjet fluids and inks improved for photoyellowing

A radiation-cured, inkjet ink technology, applied in inks, household appliances, applications, etc., can solve problems such as hindering substrate processing, not getting uniform spreading and adhesion of ink, increasing cost, complexity and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

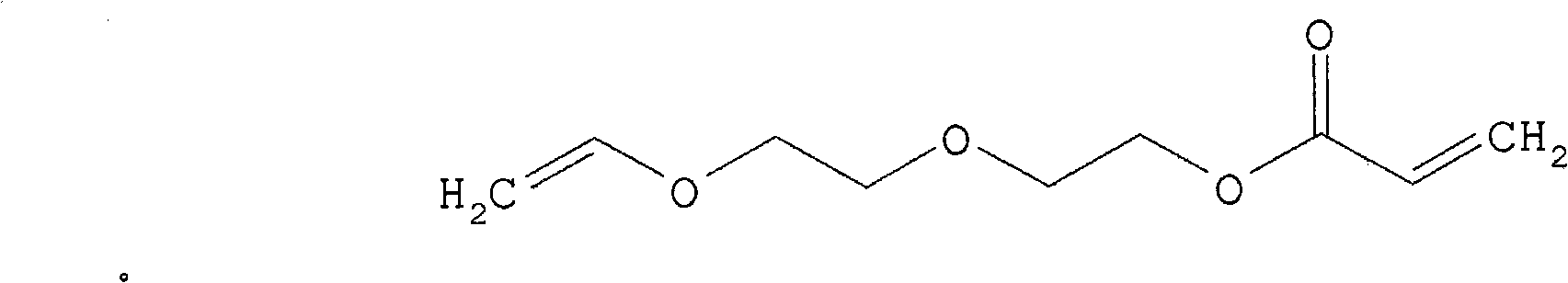

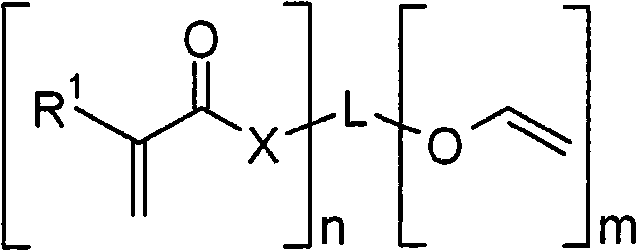

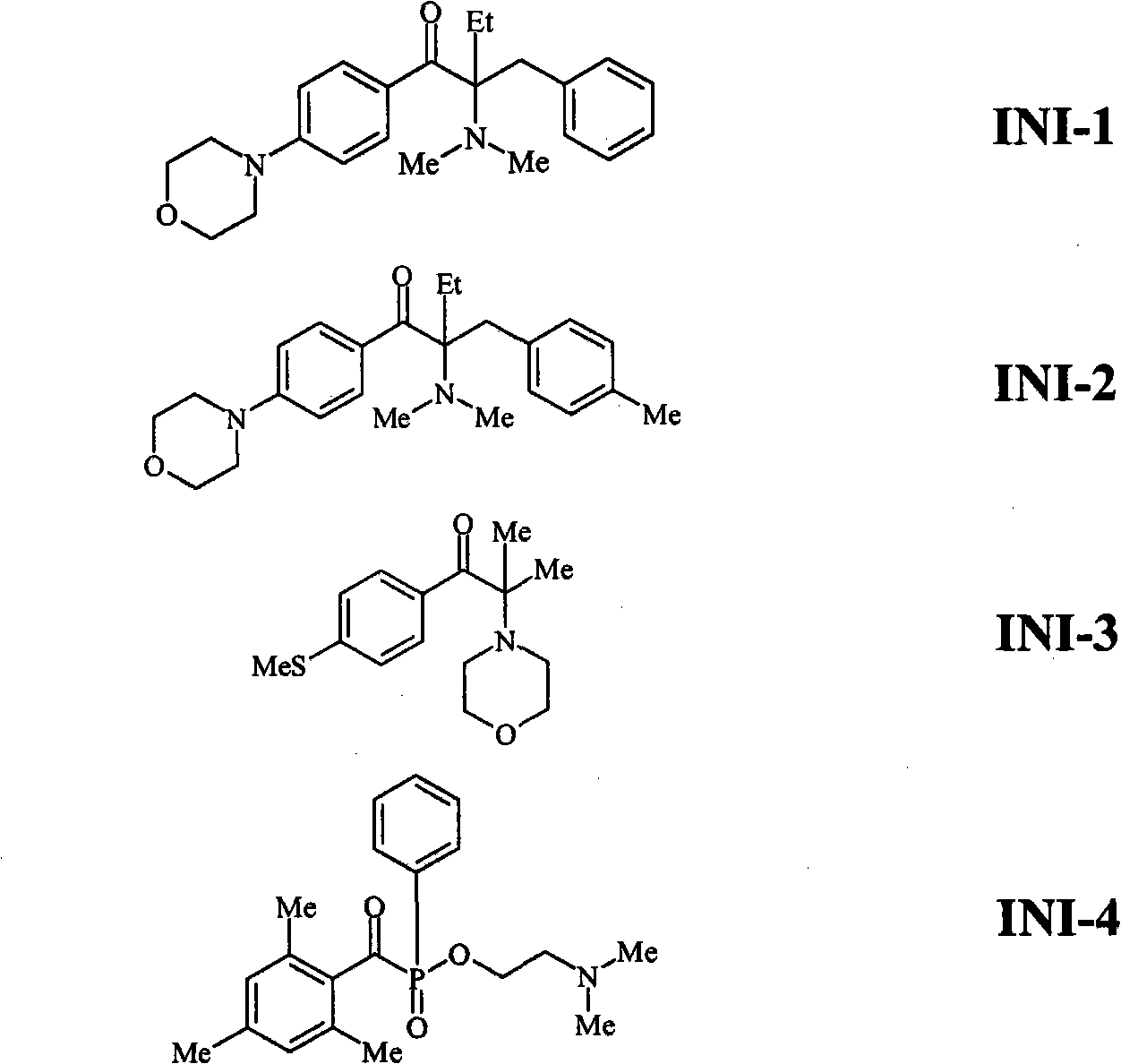

[0329] This example illustrates the effect on photoyellowing and adhesion of using a photoinitiator comprising a tertiary amine group in combination with a radiation curable composition comprising VEEA and TMPTA.

[0330] Preparation of Pigment Dispersion CPD1

[0331] Use DISPERLUX in a 6L container TM Disperser (from DISPERLUX S.A.R.L., Luxembourg) 500 g of polymeric dispersant DB162 and 33 g of polymerization inhibitor Genorad™ 16 were dissolved in 3870 g of DPGDA. Add 1000 g of cyan pigment PB15:4 to the solution and stir for 30 minutes. The vessel was then connected to a Bachofen DYNOMILL ECMPilot mill with an internal volume of 1.5 L, 42% filled with 0.4 mm yttrium stabilized zirconia beads ("High Abrasion Resistant Zirconia Grinding Media", from TOSOH Co.) . The mixture was circulated through the mill for 2 hours and 18 minutes at a flow rate of about 2 L per minute and a rotational speed of about 13 m / s in the mill. 1667 g of a 30% by weight DB162 / DPGDA solution ...

Embodiment 2

[0354] This example demonstrates that good adhesion on a broad range of substrates is obtained only when a photoinitiator comprising a tertiary amine group is used in combination with a radiation curable composition comprising a vinyl ether acrylate and a multifunctional acrylate.

[0355] Preparation of Pigment Dispersion CPD2

[0356] In a 50L container, 4200g polymeric dispersant S35000 and 420g polymerization inhibitor Genorad TM 16 was dissolved in 11680 g DPGDA. Add 8400g of cyan pigment PB15:4 to the solution and use DISPERLUX TM A disperser (from DISPERLUX S.A.R.L., Luxembourg) stirred for 10 minutes. The vessel was then connected to a Bachofen DYNOMILLECM POLY mill with an internal volume of 8.2 L, 42% filled with 0.4 mm yttrium stabilized zirconia beads ("High Abrasion Resistant Zirconia Grinding Media", from TOSOH Co.) . The mixture was circulated through the mill at a flow rate of about 10 L per minute and a rotational speed of about 15 m / s in the mill for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com