Internal combustion engine

A technology for an internal combustion engine and an exhaust port, applied in the field of internal combustion engines, can solve problems such as unsatisfactory heat transmission, and achieve the effect of a simple structure condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

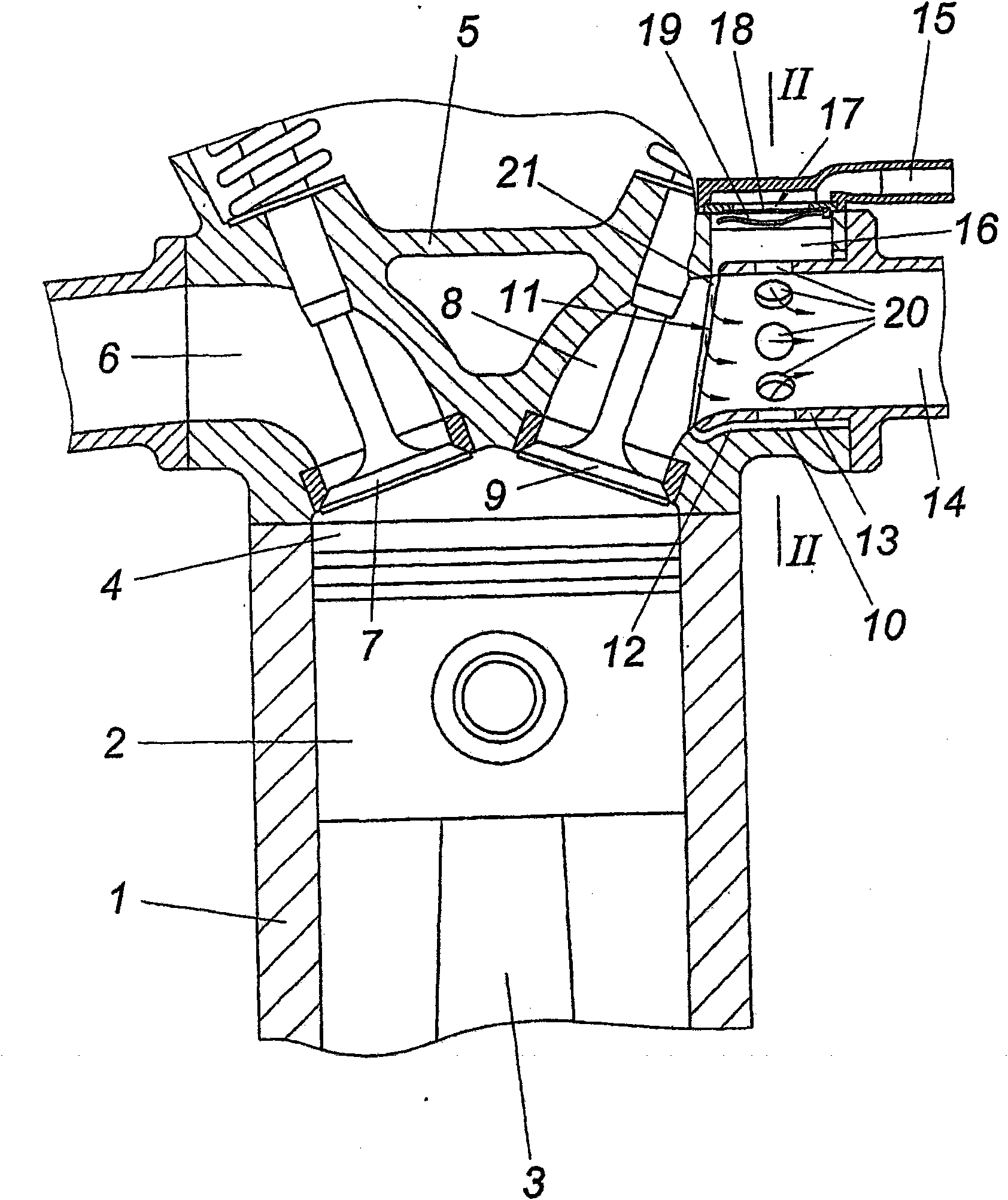

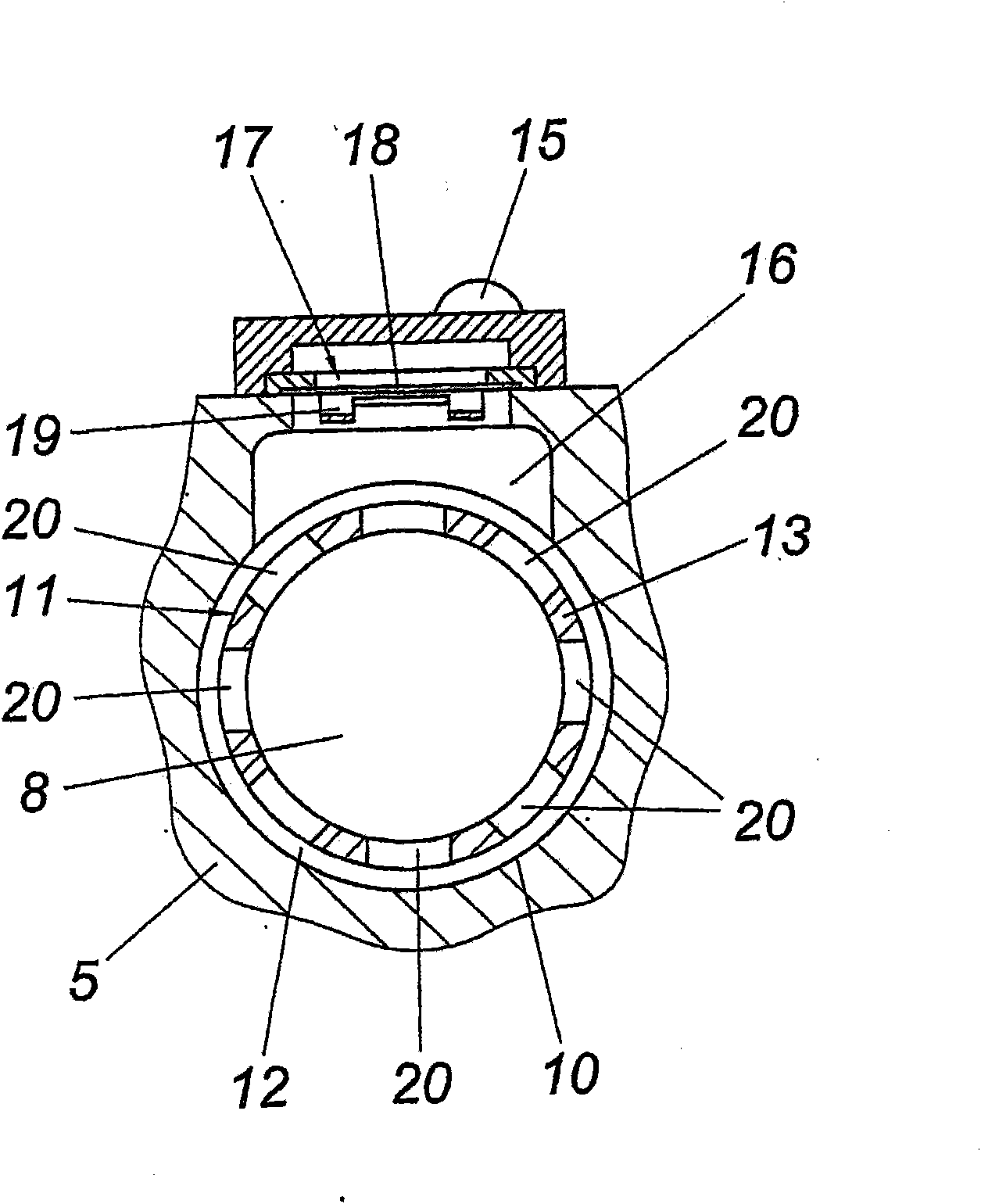

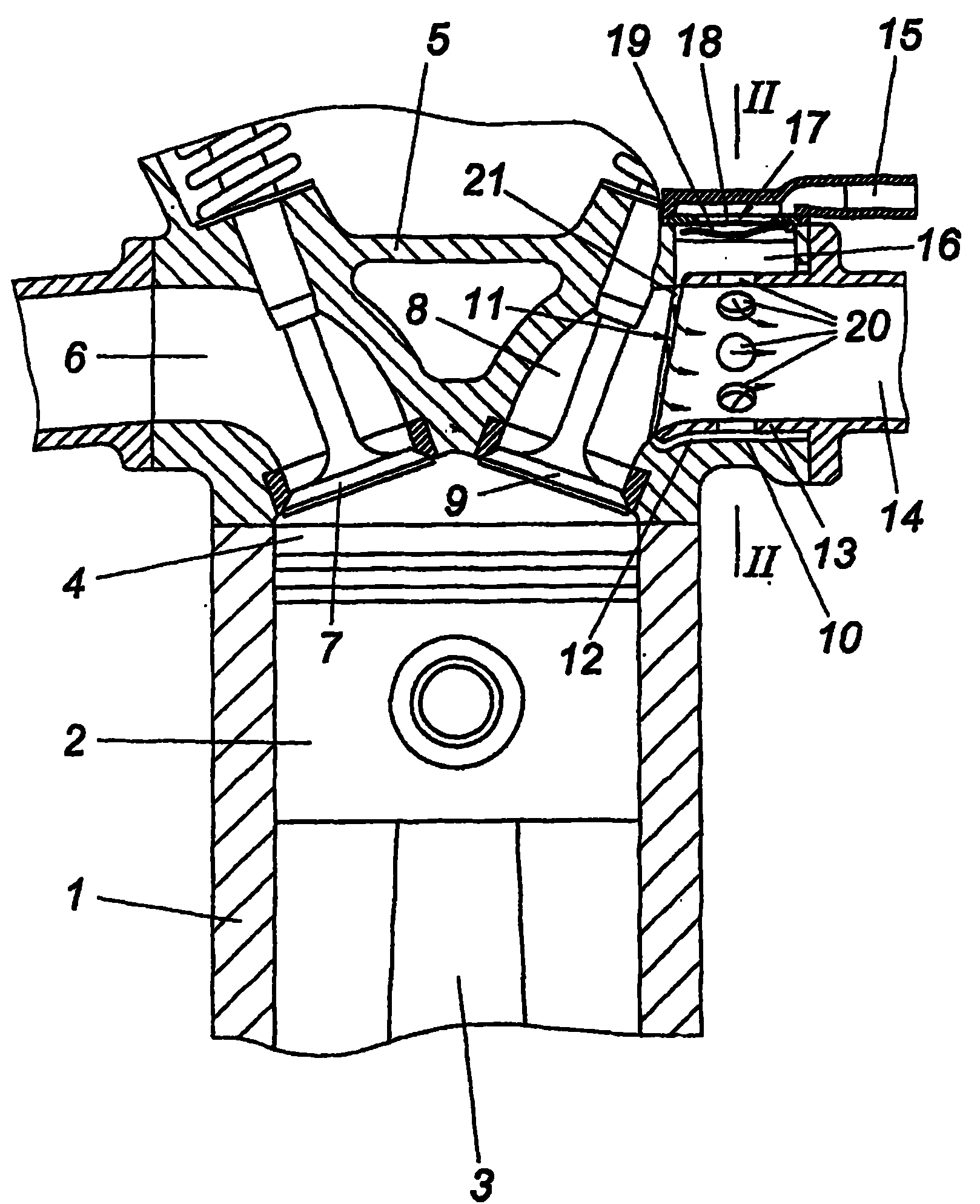

[0012] figure 1 The internal combustion engine shown has at least one cylinder 1 with a piston 2 which is connected via a connecting rod 3 to a crankshaft in a conventional manner. The combustion chamber of the cylinder 1 is closed upwards by a cylinder head 5 which is designed with at least one intake port 6 with intake valves 7 and at least one exhaust port 8 with exhaust valves 9 . The exhaust duct 8 comprises a tubular insert 11 which is accommodated in the cylinder head bore 10 , leaving an annular gap 12 between it and the cylinder head bore 10 . The insert 11 in the form of a connecting piece 13 is designed as a component of an exhaust manifold 14 which is connected to the exhaust duct 8 in a conventional manner via an exhaust elbow.

[0013] The annular gap 12 is connected with an air pipe 15 through which fresh air is fed into the exhaust branch pipe 14 for supplementary combustion of combustible residual substances. Here, the arrangement is such that the annular ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com