Anti-glare film, anti-glare polarizing plate, and image display device

An anti-glare film, polarizing plate technology, applied in polarizing elements, nonlinear optics, coatings, etc., can solve the problem of difficulty in achieving high contrast, and achieve the goal of preventing the reduction of visibility, excellent visibility, and excellent anti-glare. glare performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] (A) Production of metal molds for embossing

[0187] An iron roll having a diameter of 200 mm (STKM13A of JIS) on the surface of which Ballard copper plating (Ballard copper plating) was applied was prepared. Ballard copper plating consists of copper plating layer / thin silver plating layer / surface silver plating layer, and the overall thickness of the plating layer is about 200 μm. The surface of the copper-plated layer was mirror-polished, and further, using a sandblasting device (manufactured by Fuji Manufacturing Co., Ltd.), zirconia microbeads "TZ-B125" (trade name, average particle diameter) produced by Tosoh Corporation were 125μm), the amount of microbeads used is 6g / cm 2 (Roller surface area per 1cm 2 The amount used, hereinafter referred to as "blasting amount"), the blasting pressure is 0.05MPa (gauge pressure, the same below), the distance from the nozzle spraying microbeads to the metal surface is 600mm (hereinafter referred to as "blasting distance") ) c...

Embodiment 2~5

[0197] The refractive index and particle size (meaning the weight average particle size; the same below) of the methyl methacrylate / styrene copolymer resin beads dispersed in the light diffusion layer were changed as shown in Table 1, except that It carried out similarly to Example 1, and produced the antiglare film which consists of the laminated body of a hard-coat layer and a resin base film.

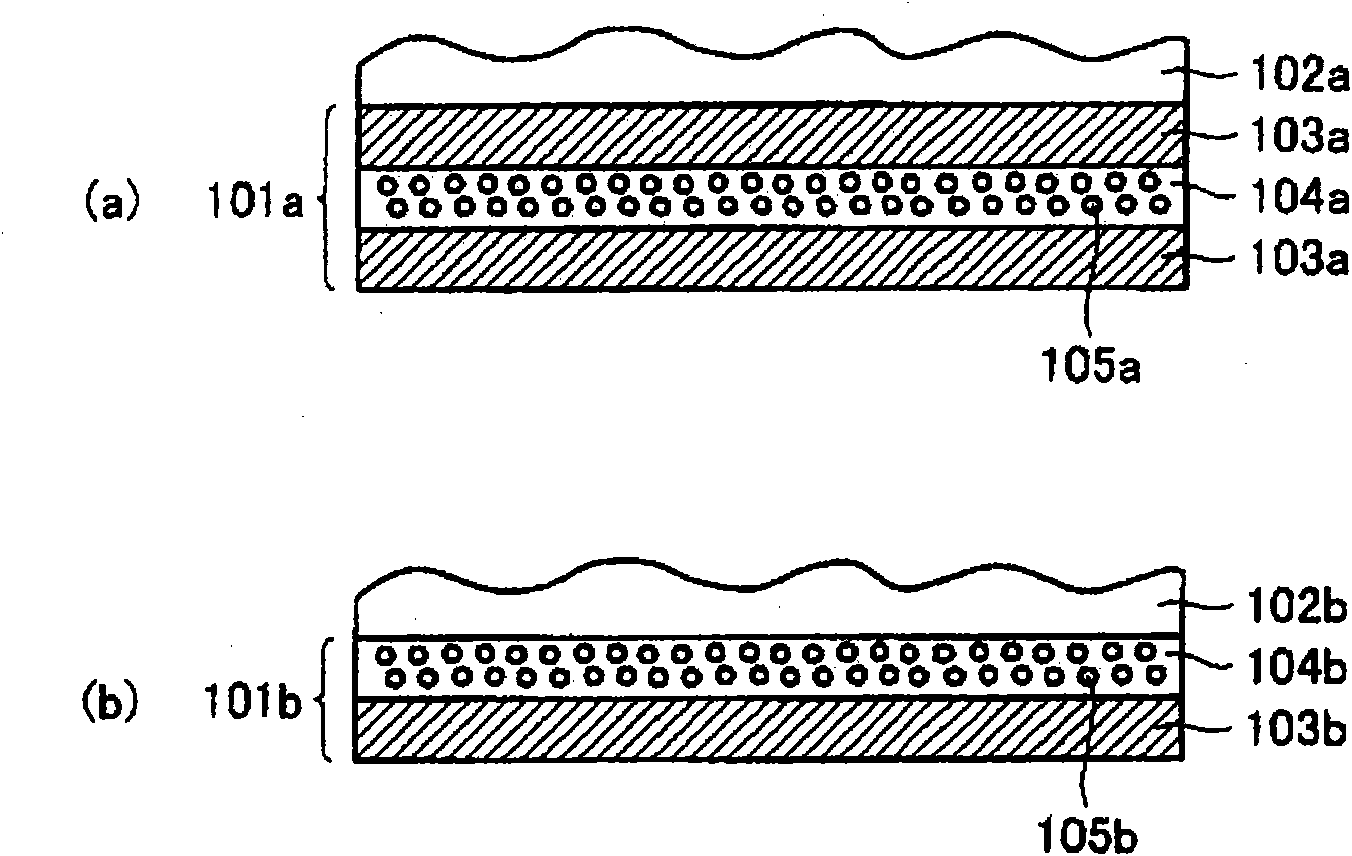

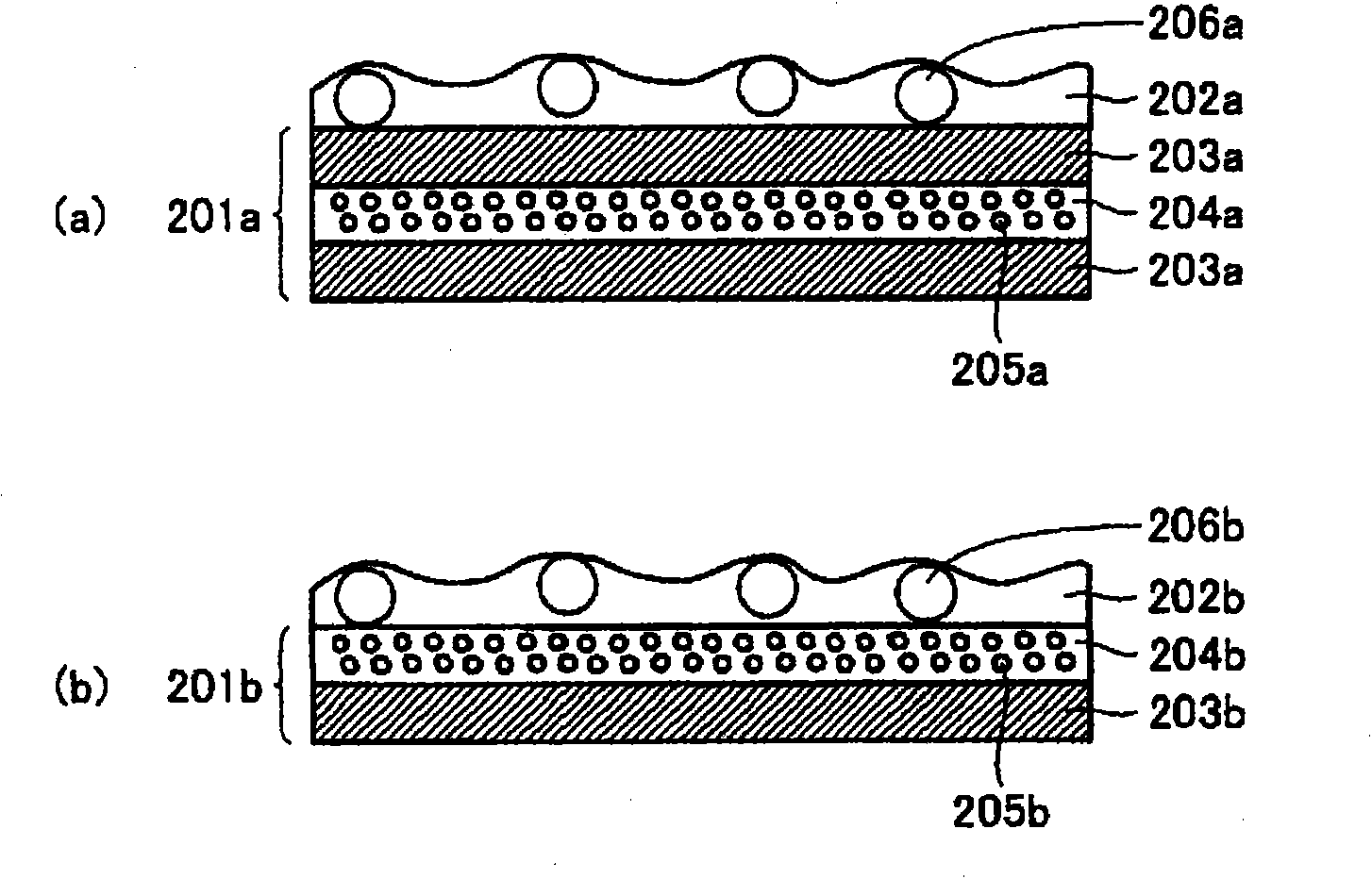

Embodiment 6 and 7

[0221] As the resin base film, a resin base film of a two-layer structure in which a light-diffusing layer (thickness 50 μm) containing fine particles and a transparent resin layer (thickness 30 μm) shown in Table 5 were laminated was used. It carried out similarly to Example 1, and produced the antiglare film which consists of the laminated body of a hard-coat layer and a resin base film. Here, the antiglare film is produced in the lamination order of transparent resin layer / light diffusion layer / hard coat layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Weight average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com