Magnesium oxide dust removal system for oriented silicon steel thermal drawing annealing unit

A technology of oriented silicon steel and dust removal system, applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of low degree of automation, huge system design, low production efficiency, etc., and achieve low energy consumption and failure rate. , The effect of reducing the system scale and reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

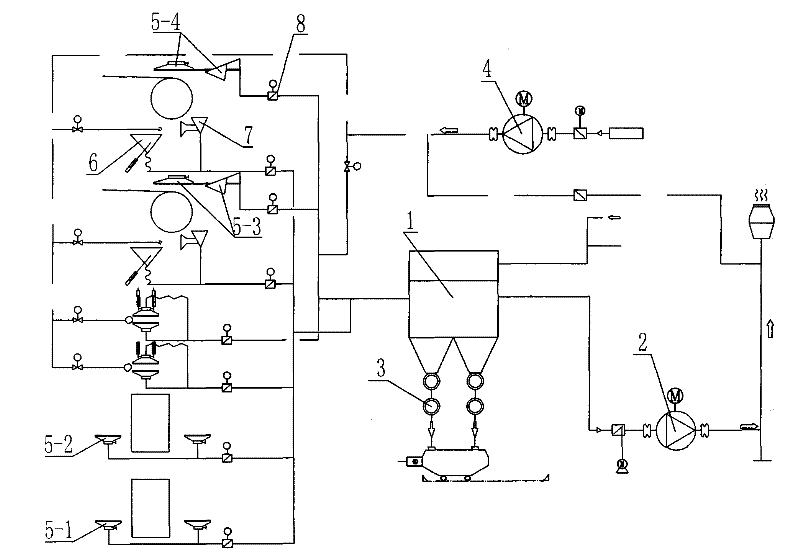

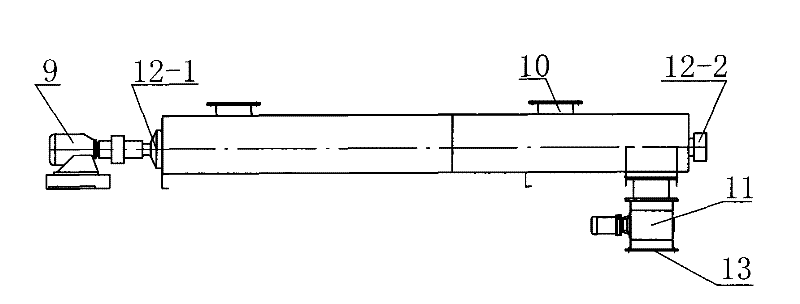

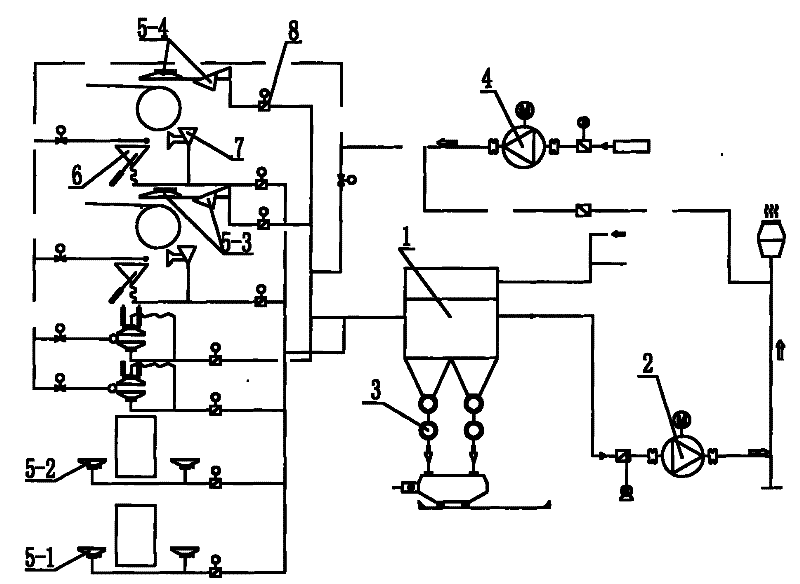

[0018] The magnesia dedusting system of an oriented silicon steel thermal drawing annealing unit provided by the present invention is mainly composed of a dust extraction facility at the front end, a dust removal and ash transportation facility in the middle and a fan drive part at the rear.

[0019] The structure of the magnesia dust removal system of the oriented silicon steel thermal drawing annealing unit of the present invention is as follows figure 1 Shown: It consists of a dust extraction hood, an air curtain 7, a pneumatic switching valve 8, ash conveying equipment 3, a dust collector 1, a dust removal fan 2, and a chimney. Among them: the dust extraction hood and air curtain 7 are installed at the uncoiler and the inlet shear, and are connected to the dust collector and fan through pneumatic valves and air pipes; the ash conveying equipment is located at the lower part of the dust collector, and is responsible for cleaning the magnesium oxide from the dust collector D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com