Surfacing method of 12-percent Cr steel high and middle pressure rotor journal of ultra supercritical steam turbine

An ultra-supercritical, steam turbine technology, applied in the field of surfacing, can solve the problems of mechanical adhesion and wear of the rotor journal and bearing surface, and the mismatch of friction pairs, so as to reduce technical dependence, ensure smooth operation, and shorten the production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

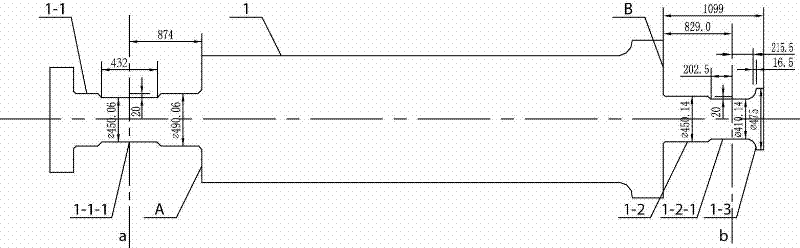

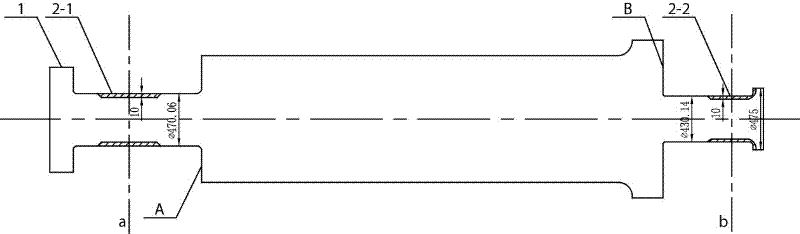

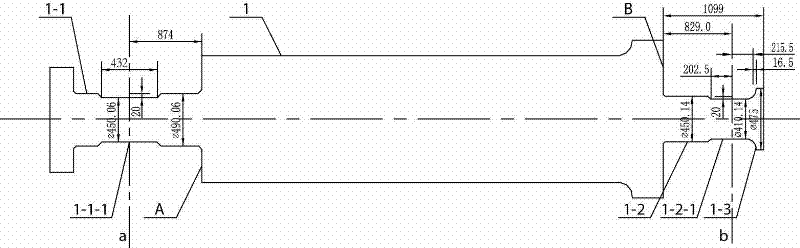

[0013] Specific implementation mode one: combine figure 1 with figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0014] Step 1. According to the groove shape, size and smoothness requirements of the drawing, the rough rotor 1 (12% Cr steel rotor, material 14Cr10.5Mo1W1NiVNbN, the chemical composition is shown in Table 1, 14 represents the carbon content, and the number behind the element symbol represents The approximate content of this element) the first journal 1-1 and the second journal 1-2 are respectively grooved, and the first bearing center line a is determined based on the first turning datum plane A, and the first bearing The center line a is an annular groove 1 with a center turning length of 432 mm and a turning thickness of 20 mm. Bevels are processed on both sides of the annular groove 1 to obtain the first surface to be surfacing 1-1-1; take the second turning reference plane Determine the center li...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, it also includes step 8, said step 8 conducts non-destructive testing on the first surfacing surface 2-1 and the second surfacing surface 2-2 of the blank rotor 1 after turning and finishing in step 7. (Ultrasonic inspection: no linear defects and dense circular defects display, there can be a single circular defect of φ<3.0mm; surface penetration inspection: no linear defects, there can be circular defects of φ<1.0mm), other steps and parameters It is the same as the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combinationfigure 1 with figure 2 This embodiment will be described. In this embodiment, in the surfacing process of step 5, during the interval of surfacing work, the first surface to be surfacing 1-1-1 and the second The surface to be surfacing 1-2-1 is kept warm at a temperature of 260°C to 320°C. Due to the heavy workload of surfacing welding, the surfacing work of the shaft journal at one end of the blank rotor 1 cannot be completed in one working day, and the surfacing work is stopped at night, and the surfacing welding will continue on the second working day. Cracks appear at the surfacing welding place, thereby improving the surfacing welding quality. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com