Charging packaging device separating two powder materials

A packaging equipment and powder technology, applied in packaging, transportation packaging, food packaging, etc., to achieve the effect of flexible and reliable operation, fewer parts and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the feeding and packaging equipment for separating two kinds of powder materials according to the present invention will be given below in conjunction with the accompanying drawings, however, the implementation of the present invention is not limited to the following embodiments.

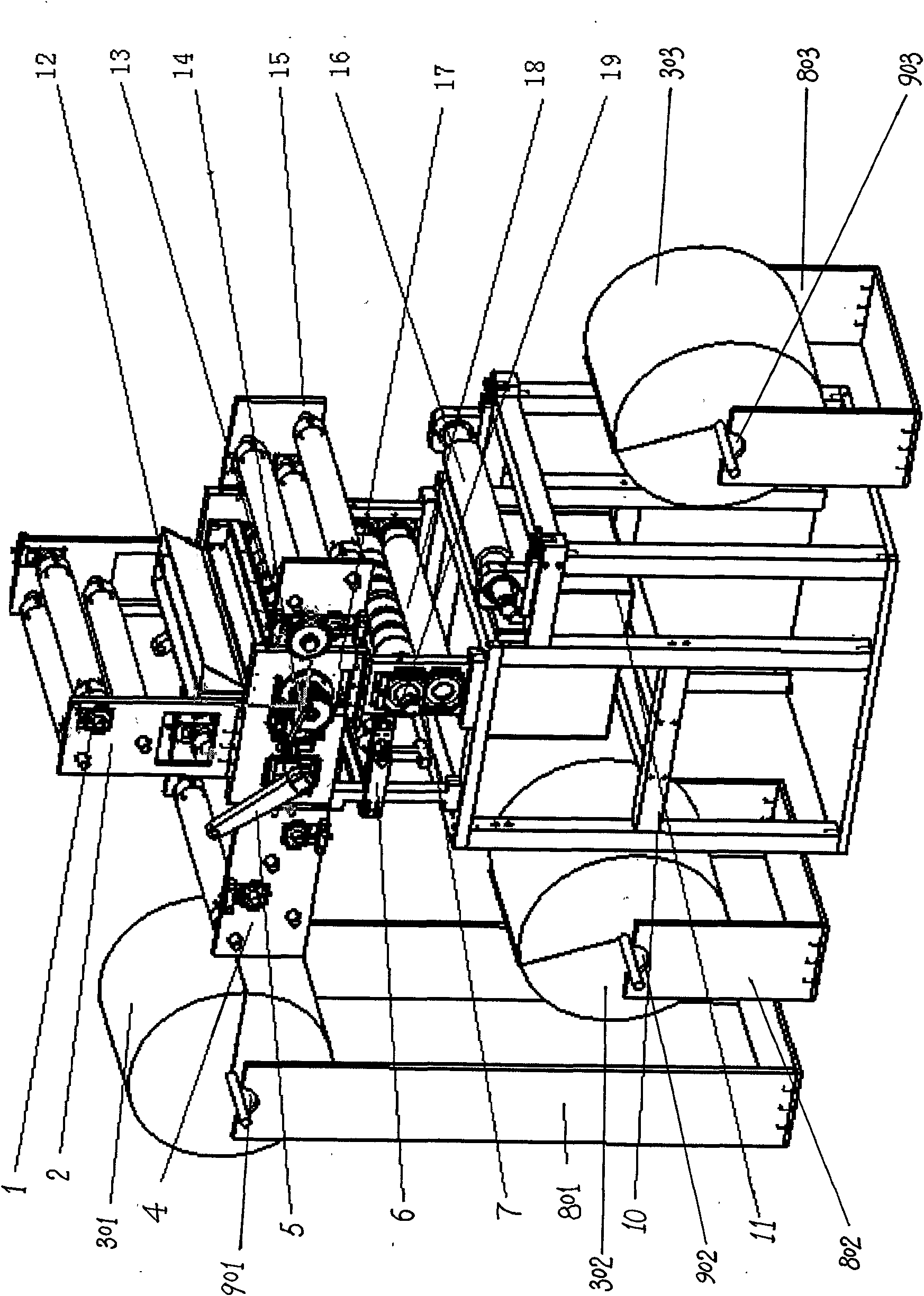

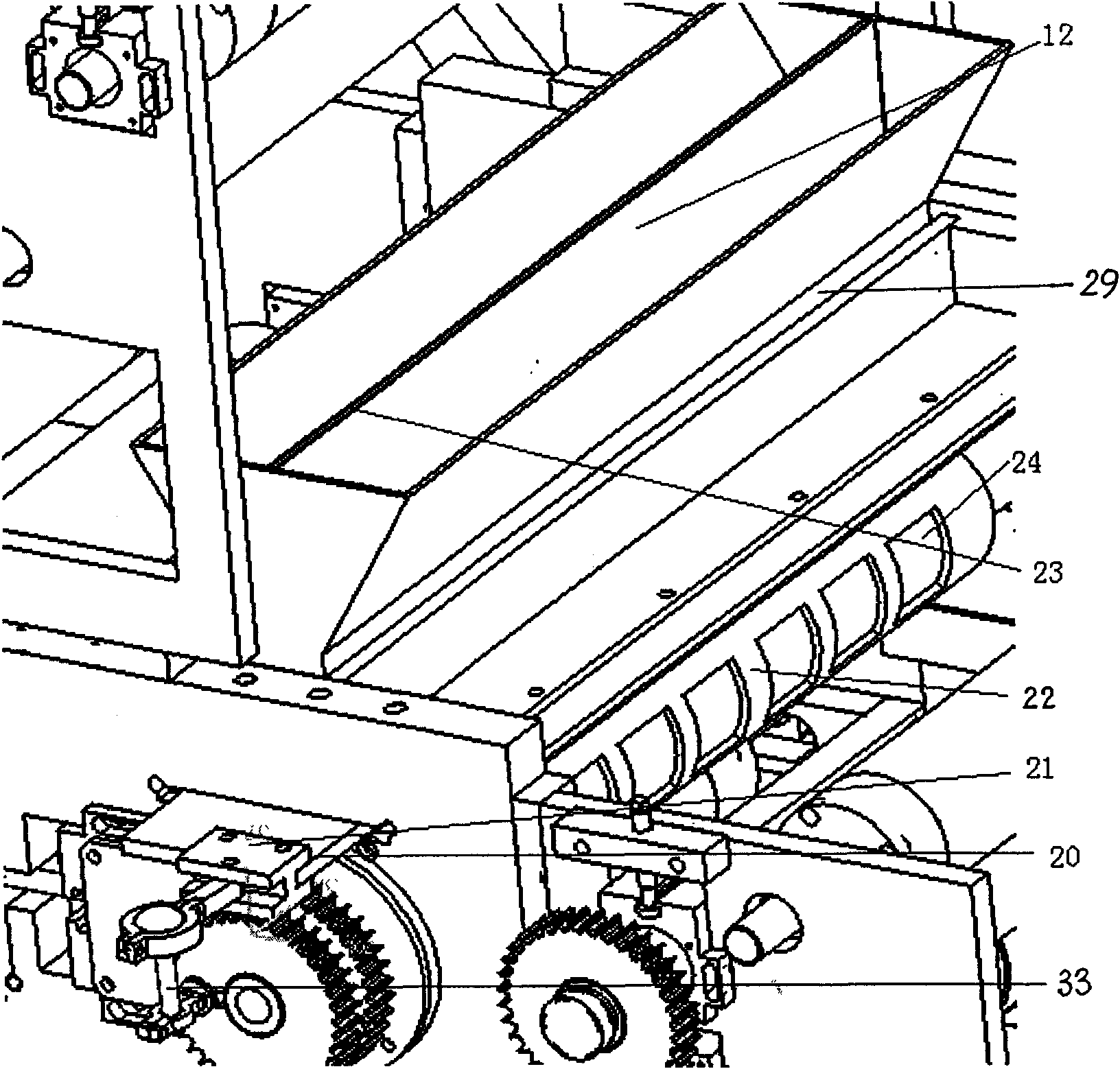

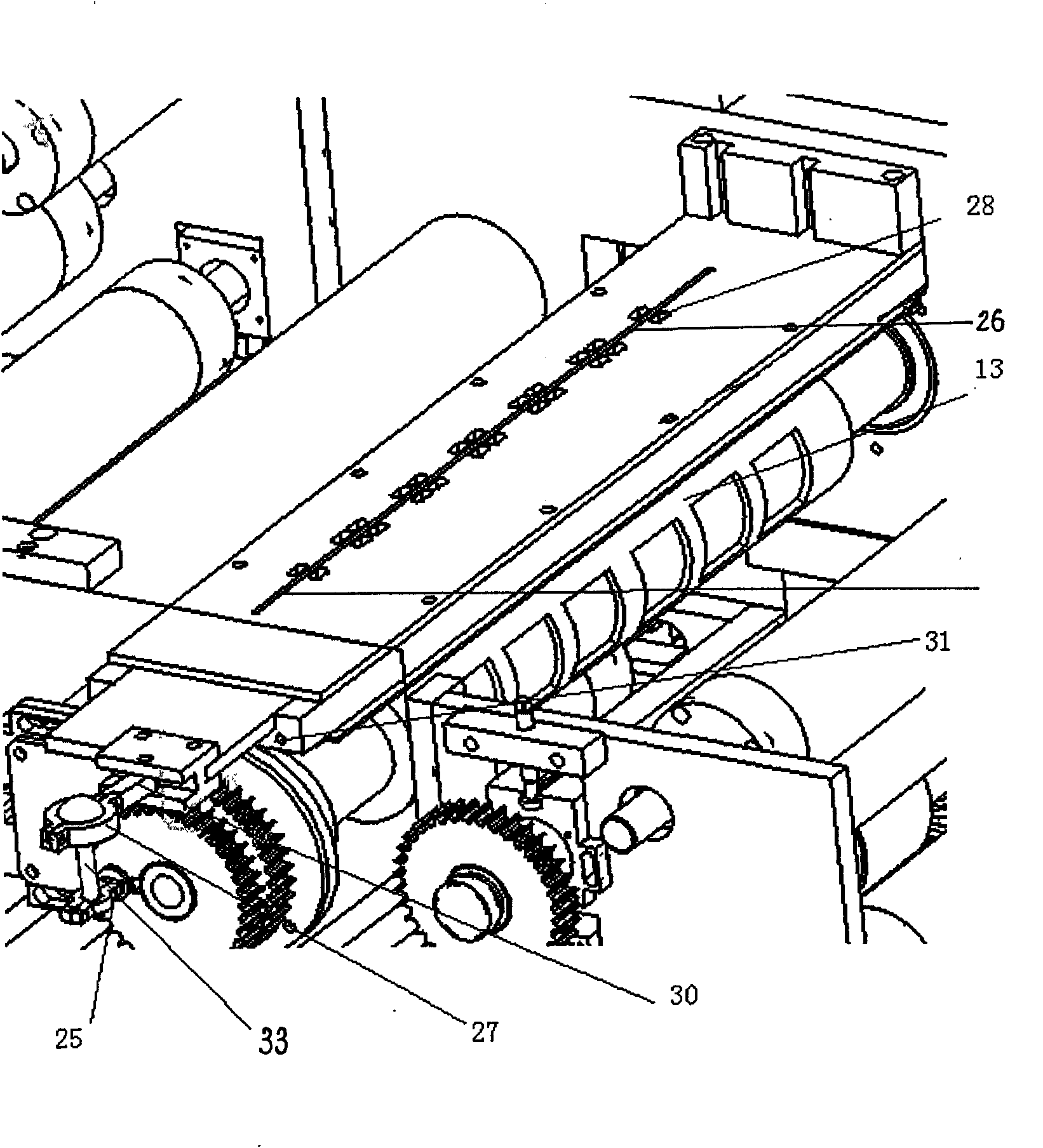

[0040] See attached figure 1 .

[0041] A feeding and packaging equipment for two kinds of powder materials at intervals, including a frame, a paper roll support, a paper roll, a paper distance adjustment mechanism 6, a conveying roller shaft mechanism 7, an electrical control box 11, a support plate 17 and an output mechanism 18; the frame A metal frame structure is adopted, consisting of a bottom bracket 101 and a middle bracket 102 . The bottom bracket 101 is actually divided into two parts: the main support part and the auxiliary support part connected by the bracket. An electrical control box 11 is arranged in the middle of the main supporting part, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com