Device for jointing dust removing air pipes of movable discharging carriage, dust removing system and method for jointing air pipes

A docking device and unloading truck technology are applied in the directions of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils. The effect of promotion and implementation, reduction of exhaust pressure loss, and improvement of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

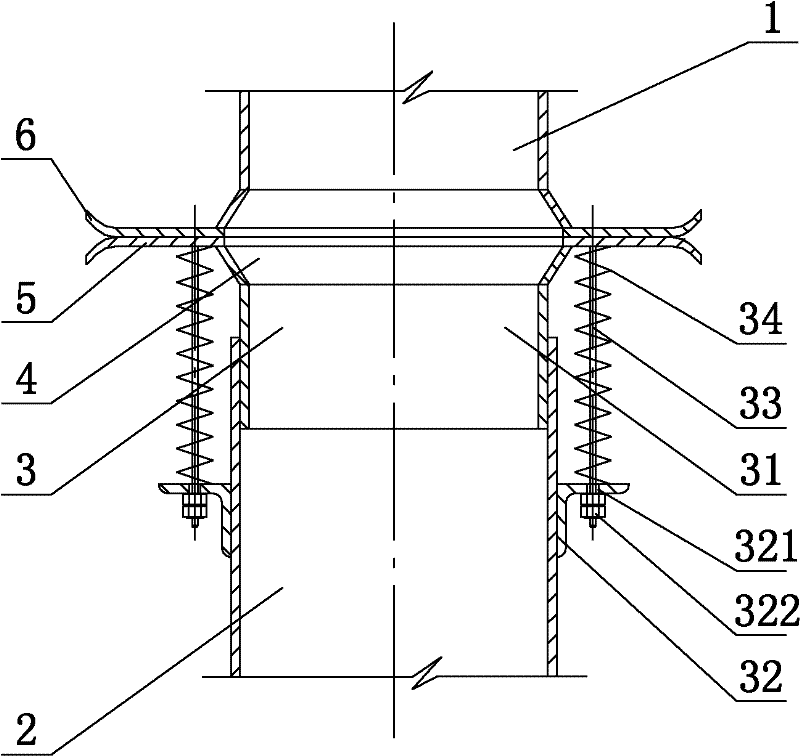

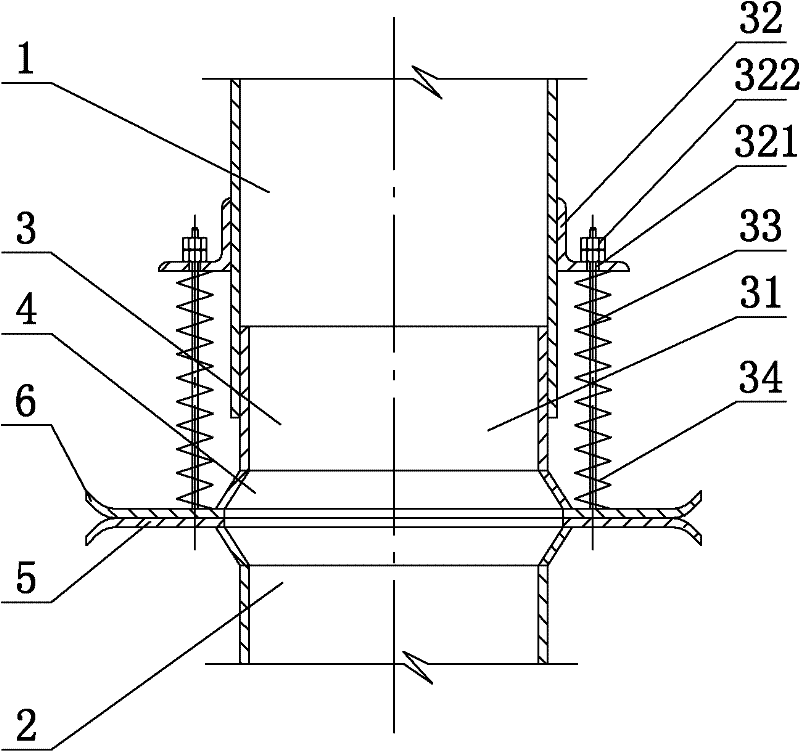

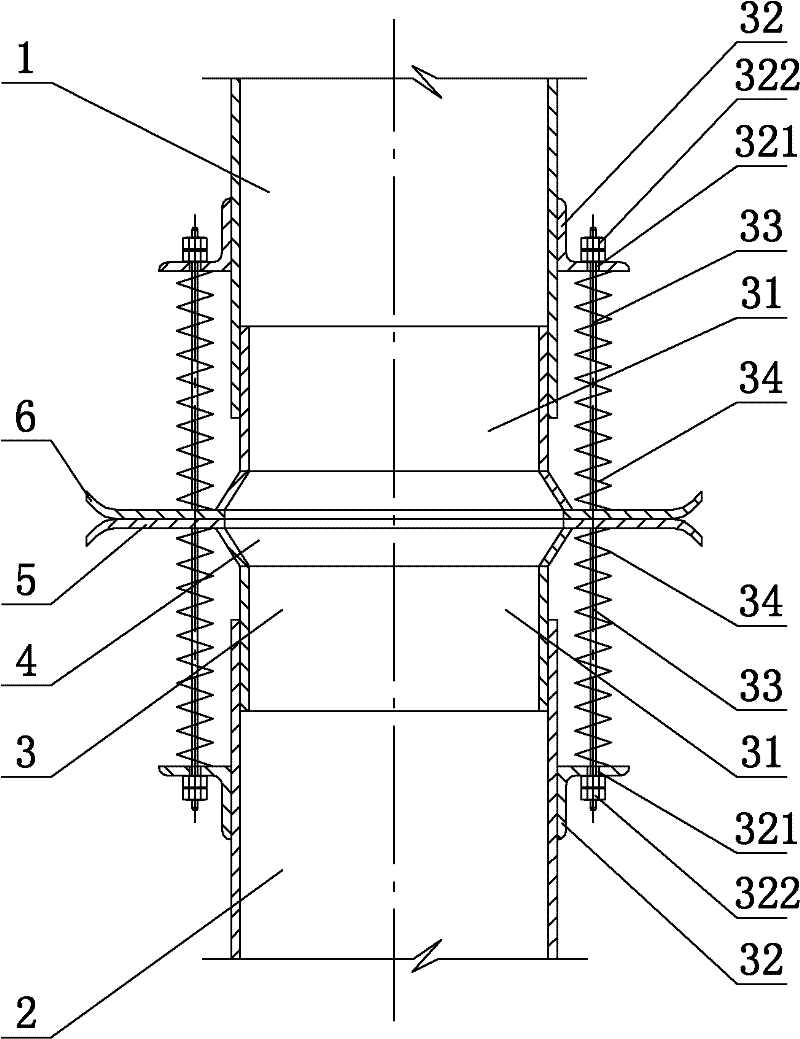

[0021] figure 1 and Figure 4 It shows an embodiment of a dust removal air duct docking device for a mobile unloading vehicle of the present invention, which includes a fixed butt joint pipe 1 fixed on the main air duct 12 in the factory building and a mobile pair mounted on the mobile unloading vehicle 10 Connecting pipe 2, at least one of the two types of butt connecting pipes is provided with an elastic telescopic section 3 at the butt end. When the two butt connecting pipes are docked, the elastic telescopic section 3 presses against each other and makes close contact, which can avoid radial butt joint gaps and reduce the exhaust pressure Loss, enhance the dust removal effect, and improve the operating environment for workers.

[0022] In this embodiment, the elastic telescopic section 3 is installed on the mobile docking pipe 2, and a gradual expansion pipe 4 is connected to the elastic telescopic section 3 and the fixed docking pipe 1, and the small-diameter ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com