Servo puffing and direct-blowing mechanism

A technology of blowing mechanism and servo motor, applied in the direction of blowing head, etc., can solve the problems of high operating level requirements of operators, poor working environment, poor labor intensity, unstable work of the mechanism, etc., to improve operability and safety, Institutional response is intuitive and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

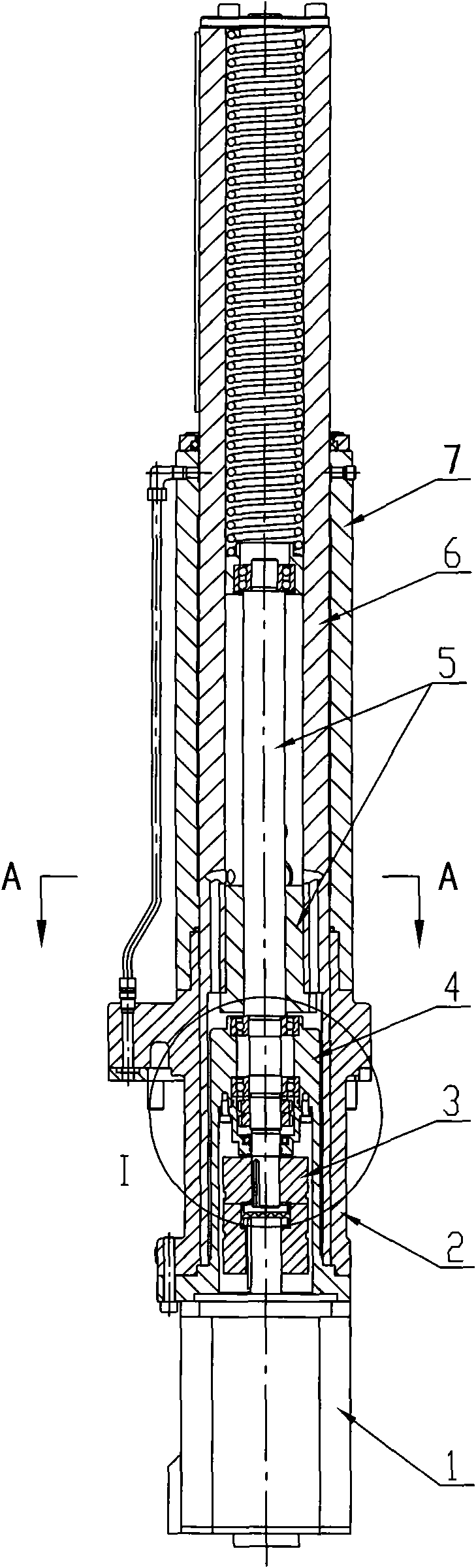

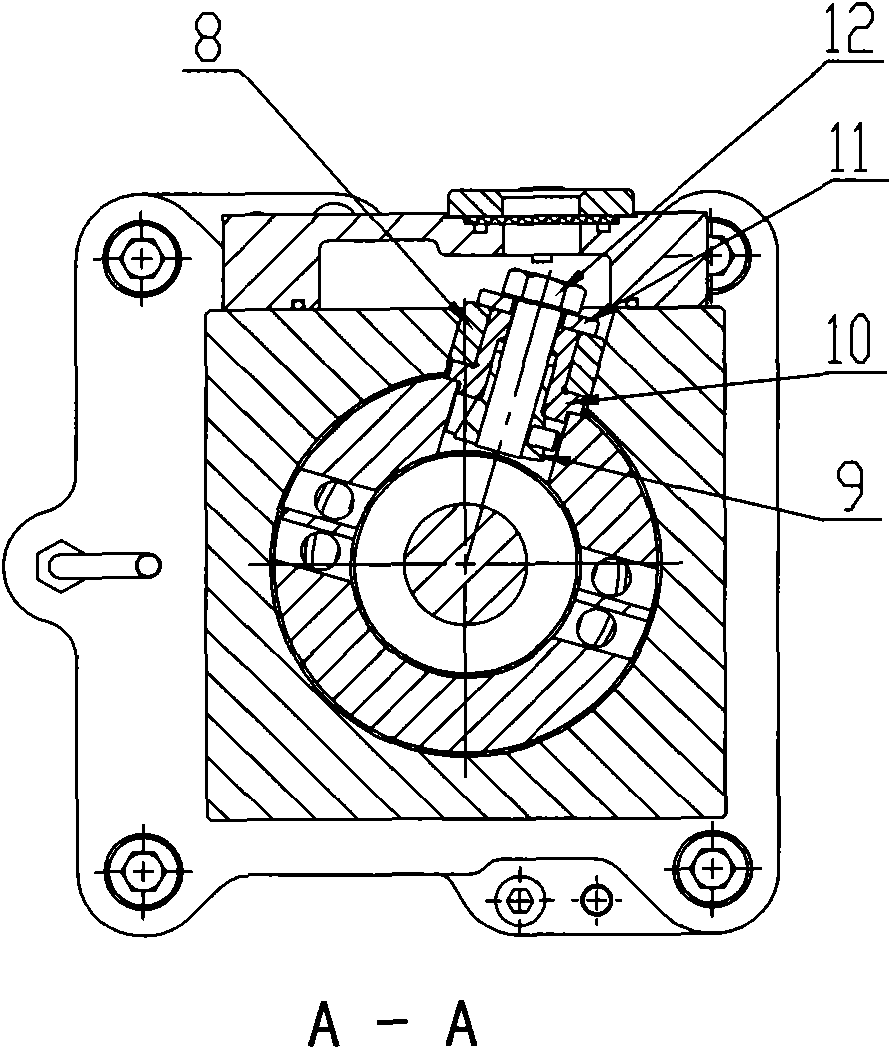

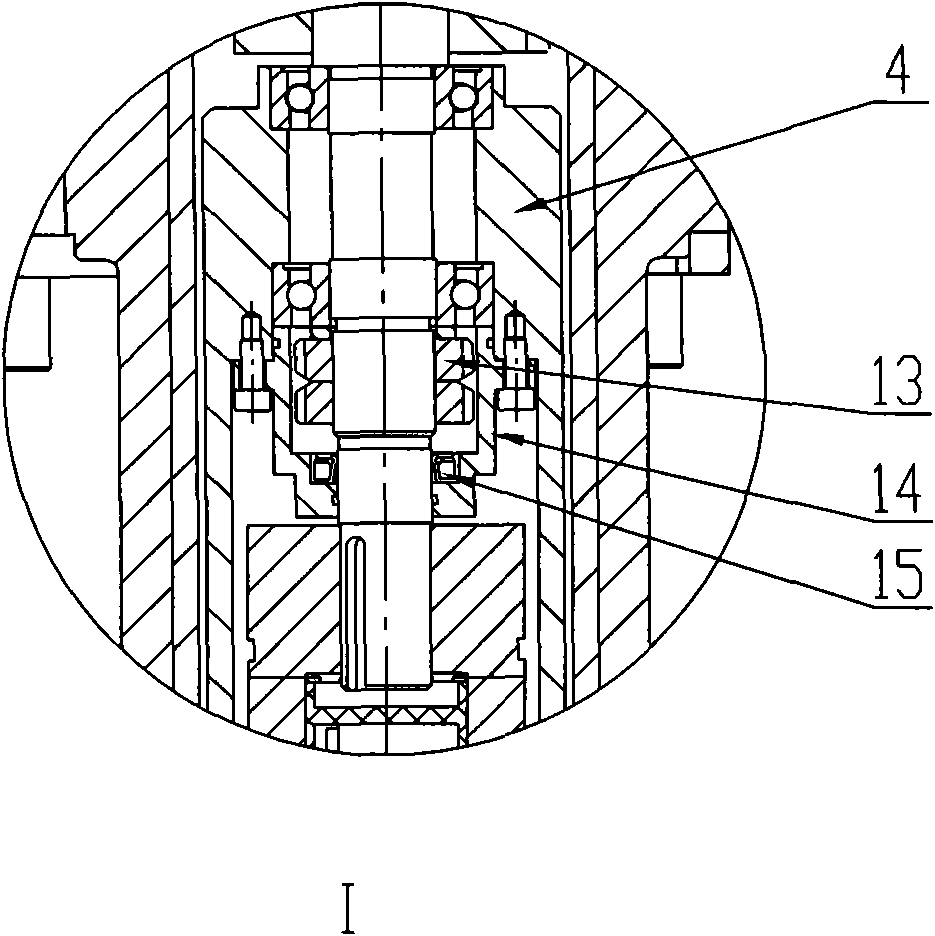

[0016] Attached below Figure 1-7 The servo puffing and positive blowing mechanism of the present invention will be further described in detail:

[0017] refer to Figure 1-7 :

[0018] The servo blowing and forward blowing mechanism is installed in a vertical hole on the frame and fixed on the frame. The bottle making machine is generally composed of multiple frames with working mechanisms installed side by side. Each frame assembly is individually Work, and finally transport the product to the bottle conveyor. The whole machine is controlled by an electronic timing system, so that each frame does not interfere with each other, that is to say, the products transported to the bottle conveyor will not collide and have the same spacing. In the servo blowing mechanism, the main shaft 6 moves up and down reciprocatingly. When the main shaft 6 descends, it carries the blowing arm and falls to the correct position above the mould, so as to perform the blowing process. After the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com