Building material prepared from dredged sand and preparation method thereof

A technology for building materials and raw materials, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of lack of good treatment methods for dredged sand, restricted application, and high compressive strength, and improve environmental protection and energy saving. effect, realization of waste utilization, effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

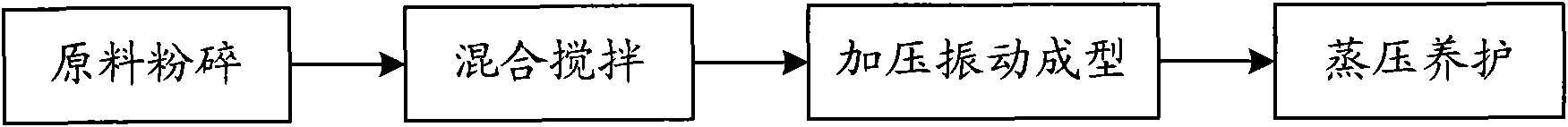

Method used

Image

Examples

Embodiment 1

[0036] According to the weight ratio, with 85Kg dredging sand, 7Kg quicklime, 3Kg fly ash, 4Kg oyster shell, 1Kg carbon fiber, 0.2Kg plasticizer, 0.1Kg dechlorination agent, 2Kg cement as raw materials, crush each raw material to 190 mesh, Then mix and stir.

[0037] Put the stirred raw materials into the brick forming mold, apply a forming pressure of 65 MPa, and vibrate forming at the vibration frequency of 2 Hz.

[0038] The formed product is autoclaved and cured under a pressure of 0.6 MPa to obtain dredged sand brick building materials. After measurement, the compressive strength of the dredged sand brick is 52MPa, and the tensile strength is 20MPa.

Embodiment 2

[0040] According to the weight ratio, use 60Kg dredging sand, 7Kg quicklime, 9Kg fly ash, 3Kg scallop shell, 1.2Kg glass fiber, 0.3Kg antirust agent, 0.1Kg chlorine remover, 2Kg cement as raw materials, and crush each raw material to 200 mesh, then mix and stir.

[0041] The stirred raw materials are put into a plate forming mold, and a forming pressure of 50 MPa is applied while forming by vibration, and the vibration frequency is 2 Hz.

[0042] The molded product is autoclaved and cured under a pressure of 0.3 MPa to obtain a dredged sand board building material. After measurement, the compressive strength of the dredged sand board is 38MPa, and the tensile strength is 16MPa.

Embodiment 3

[0044] According to the weight ratio, use 75Kg dredging sand, 5Kg quicklime, 2Kg fly ash, 3Kg oyster shell, 2Kg ceramic fiber, 0.3Kg steam culture agent, 0.1Kg dechlorination agent as raw materials, crush each raw material to 200 mesh, and then mix Stir.

[0045] Put the stirred raw materials into the block forming mold, apply a forming pressure of 50 MPa, and vibrate forming at the vibration frequency of 1.2 Hz.

[0046] The molded product is autoclaved and cured under a pressure of 0.5 MPa to obtain a dredged sand block building material. After measurement, the compressive strength of the dredged sand block is 40MPa, and the tensile strength is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com