Production process of o-fluoronitrobenzene

A technology for o-fluoronitrobenzene and production process, which is applied in the field of production technology of o-fluoronitrobenzene, can solve the problems of difficulty in recovering odor, difficulty in recovering sulfolane, easy explosion of nitro compounds, etc., and achieves scientific and reasonable process design. , easy recovery, high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further explained below in conjunction with specific examples.

[0014] The specific production process of o-fluoronitrobenzene, the steps are as follows:

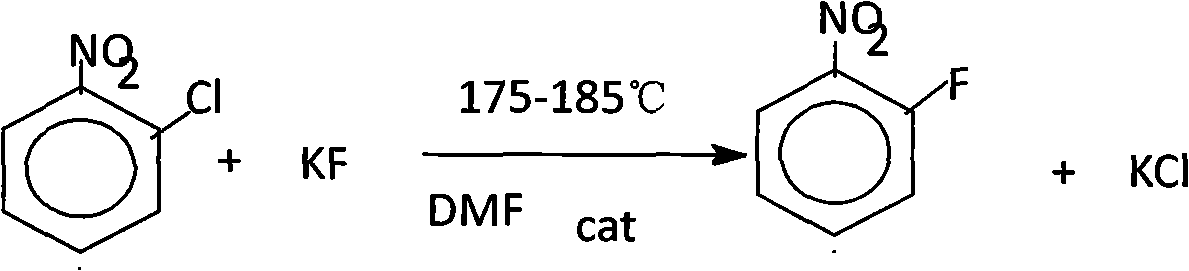

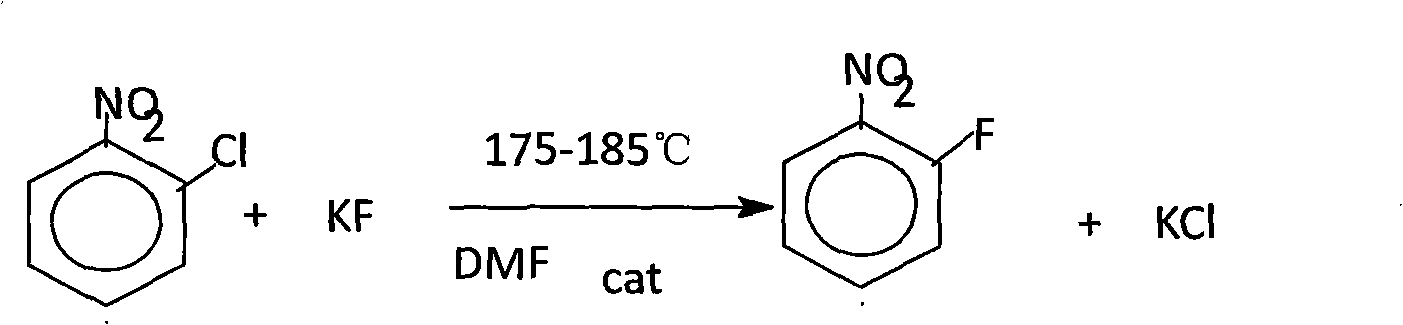

[0015] (1) Fluorination: add o-chloronitrobenzene, tetramethylammonium chloride, DMF, and potassium fluoride into the kettle (note that potassium fluoride must be added quickly, and try to avoid its contact with air), heat up under stirring, and keep The reaction is carried out at a temperature of 175-185°C. Sampling was carried out after 4 hours of reaction. If the content of o-fluoronitrobenzene in the raw material was less than 3% (GC normalization subtracted solvent analysis), the reaction was considered to be over. If > 3%, continue to keep warm until the standard is reached. The reaction was stopped and distillation under reduced pressure was started.

[0016] (2) Distillation under reduced pressure: first slowly evacuate to prevent bumping, and when the temperature of the kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com