Ceramic thyratron

A technology of thyratron and ceramics, which is applied in the field of thyratron, can solve problems such as long-term stable work and difficulty in universal replacement, and achieve the effects of ensuring conduction and heat dissipation capabilities, excellent heat dissipation performance, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

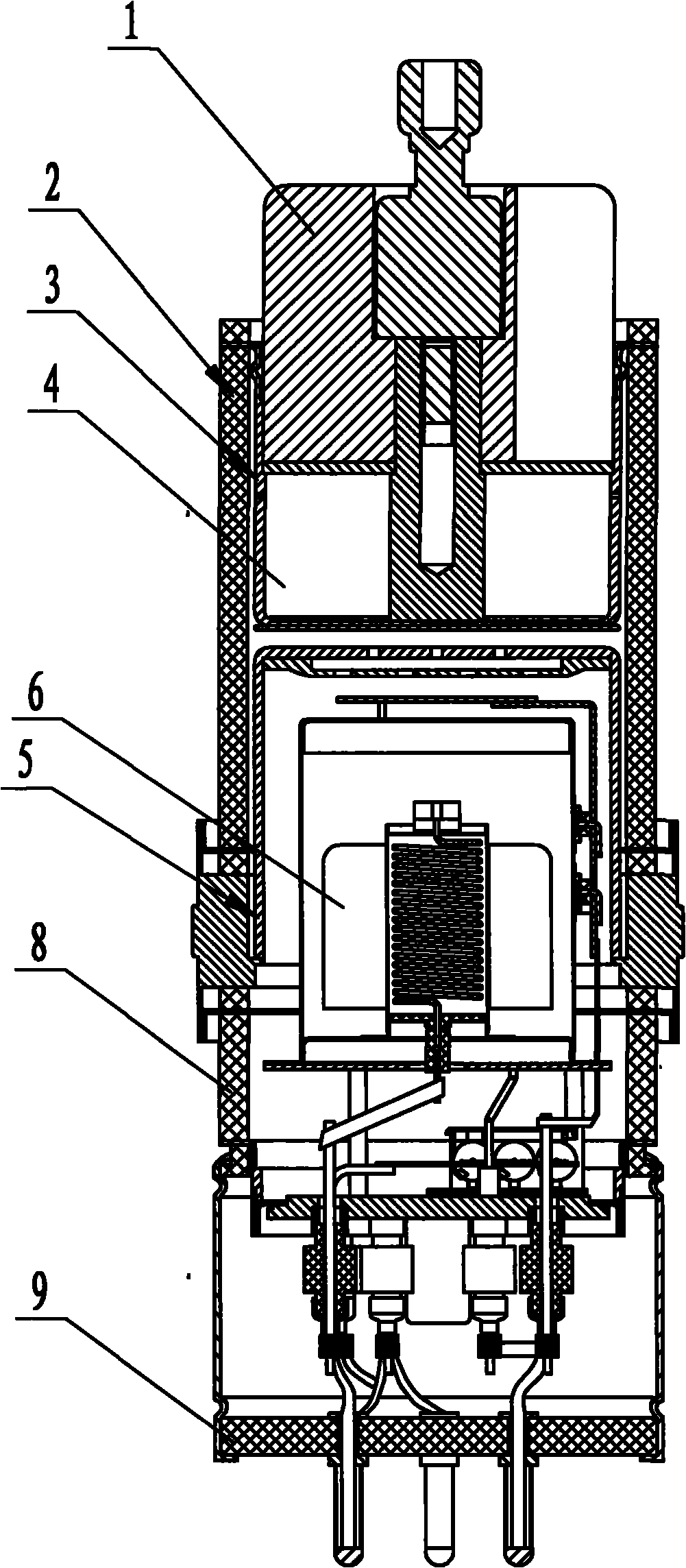

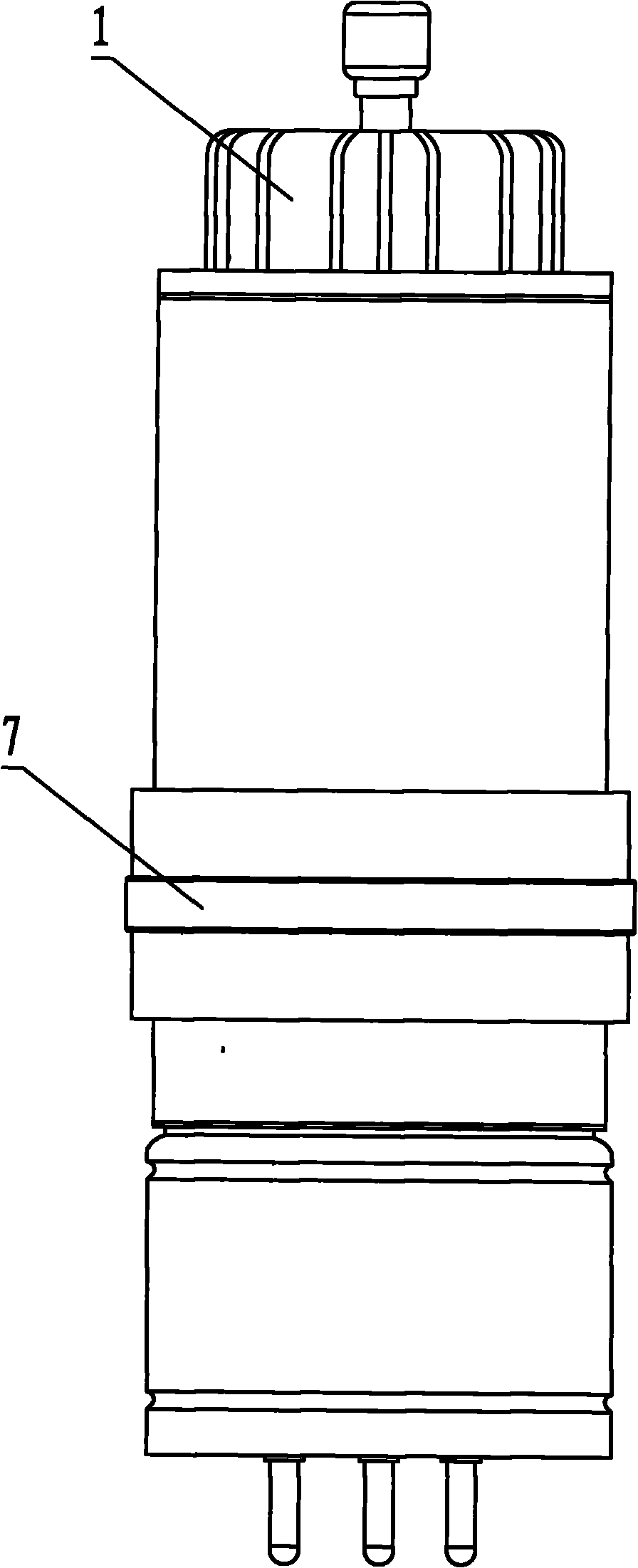

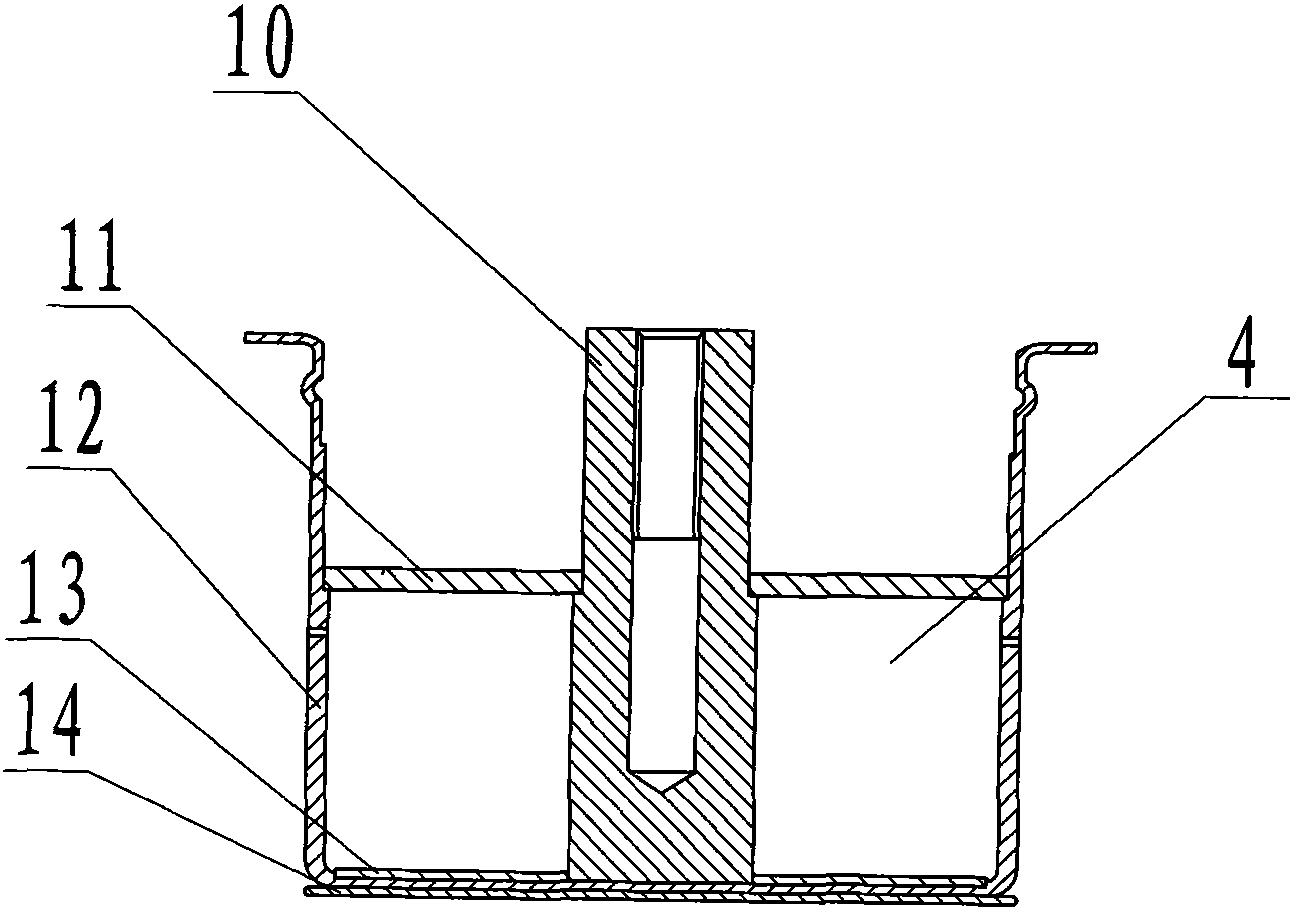

[0020] Embodiment: A ceramic thyratron, including an anode part 3, a grid part 5 and a cathode part 6, the grid part 5 is composed of a grid baffle 18, a grid cup 19 and a control grid lead 21, the grid baffle The plate 18 is fixedly placed on the bottom of the grid cup 19, and the control grid lead wire 21 is fixedly connected to the cup mouth of the grid cup 19. Based on the assembly direction: the lower part of the anode ceramic seal 2 is fixedly connected to the grid part 5, and the grid part 5 is fixed to the bottom of the grid. The pole part 5 is fixedly connected to the upper part of the cathode grid part 8, the position of the tube base part 9 is fixed below the cathode part 8, the position of the cathode part 6 is fixed between the grid part 5 and the tube base part 9, and the anode part 3 is fixedly positioned on the anode On the porcelain seal 2; the anode part 3 includes a molybdenum anode 14, a lining plate 13, an anode cup 12, an anode plate 11 and an anode lead 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com