Organic electroluminescent diode apparatus

An electroluminescent layer, electroluminescent technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of ITO thin film morphology, carrier transport and injection performance difficult to control, and organic electroluminescent device reliability. Guarantee, unstable performance of organic electroluminescent devices, etc., to achieve excellent carrier transport and injection performance, avoid rapid aging, and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

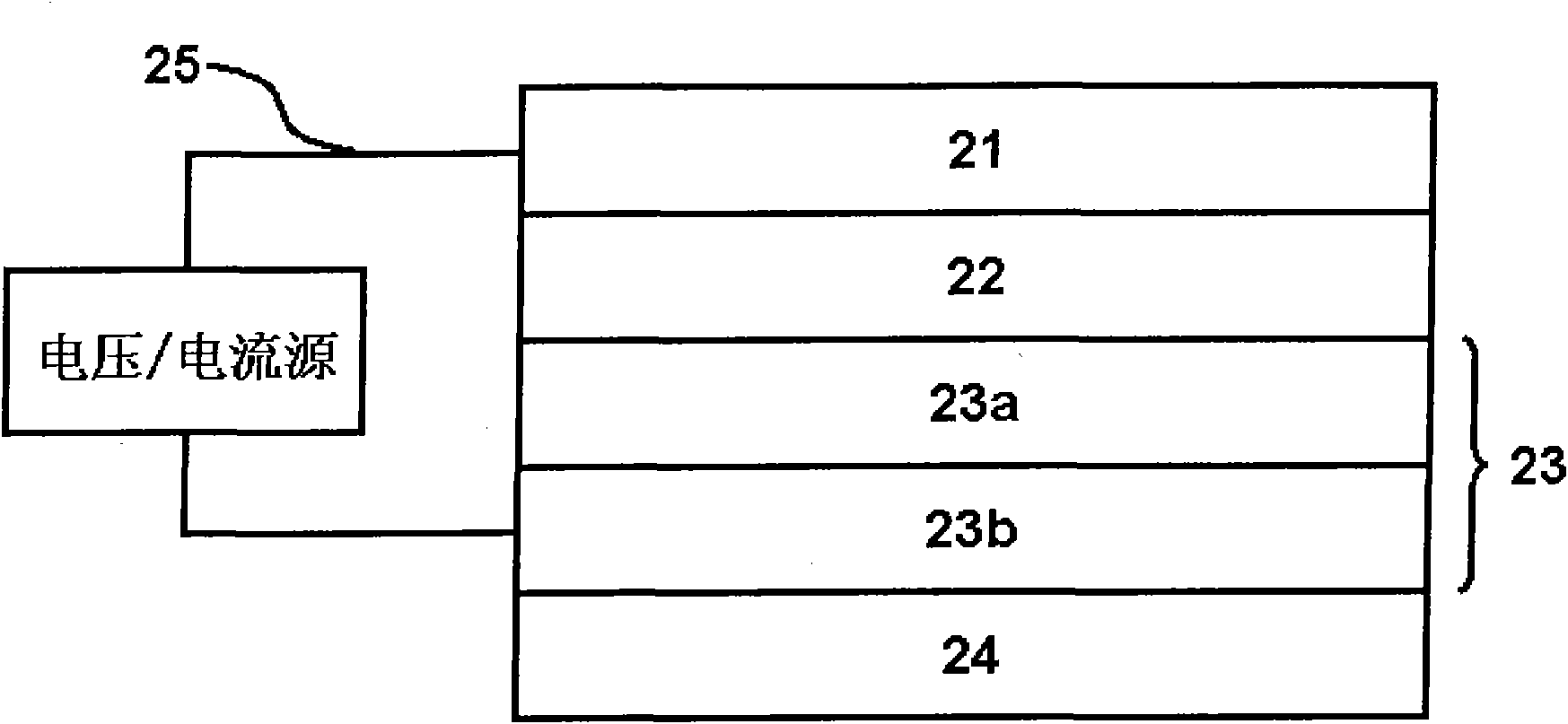

[0031] see figure 2, the organic electroluminescent device has three structural layers: an anode 23, an organic electroluminescent layer 22 and a cathode 21; their structural relationship is that the organic electroluminescent layer 22 is between the anode 23 and the cathode 21. The anode 23 of the device is composed of two parts: a metal aluminum layer 23b and a molybdenum oxide (MoOx) 23a layer, wherein the molybdenum oxide (MoOx) 23a is between the metal aluminum layer 23b and the organic electroluminescence layer 22 . The thickness of the metal aluminum layer 23b is selected between 0.1nm and 200nm; the thickness of the molybdenum oxide layer 23a formed on the metal aluminum layer 23b is between 0.1nm and 5000nm. The structural formula of molybdenum oxide in the molybdenum oxide layer 23a is MoOx, wherein the value of x is between 2 and 3, and the value of x can be equal to 2 or 3. The organic electroluminescent layer 22 is sequentially formed on the molybdenum oxide lay...

Embodiment 2

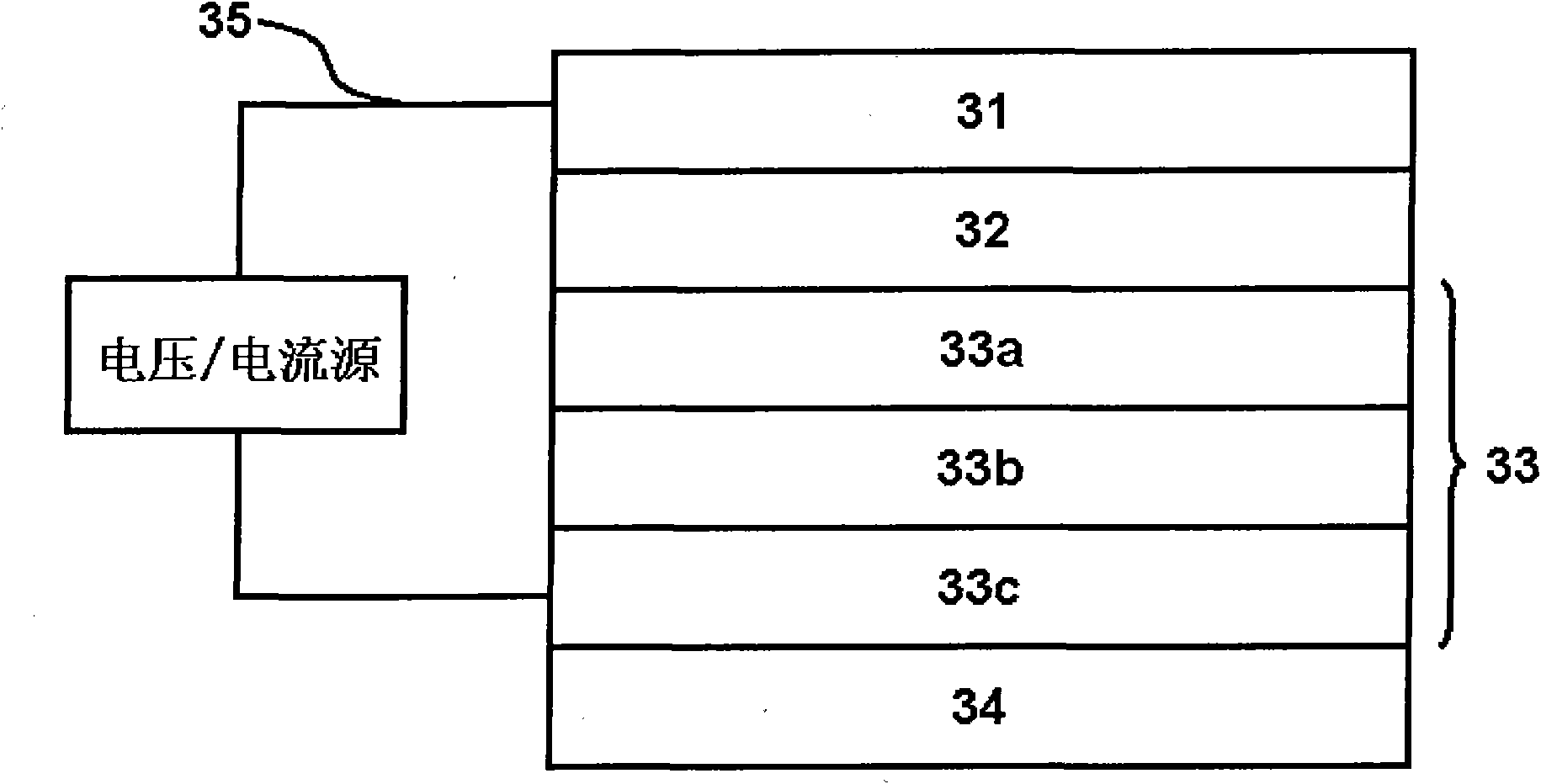

[0035] see image 3 , the organic electroluminescent device has three structural layers: an anode 33 , an organic electroluminescent layer 32 and a cathode 31 ; their structural relationship is that the organic electroluminescent layer 32 is between the anode 33 and the cathode 31 . The anode 33 of the device is composed of three parts: a molybdenum oxide layer 33a, a metal aluminum layer 33b, and a multilayer metal layer 33c. The organic electroluminescent layer 32 is sequentially formed on the molybdenum oxide layer 33 a , and the cathode 31 is formed on the organic electroluminescent layer 32 . The thickness of the molybdenum oxide layer 33a is between 0.1nm and 5000nm; the thickness of the metal aluminum layer 33b is between 0.1nm and 200nm; the thickness of the multilayer metal layer 33c is between 0.1nm and 200nm. The structural formula of molybdenum oxide in the molybdenum oxide layer 33a is MoOx, wherein the value of x is between 2 and 3, and the value of x can be equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com