Method for preparing Ru-based/Pt skin film nano-film electrode for fuel cell

A fuel cell, nano-film technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of inability to directly apply measurement and high Pt content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

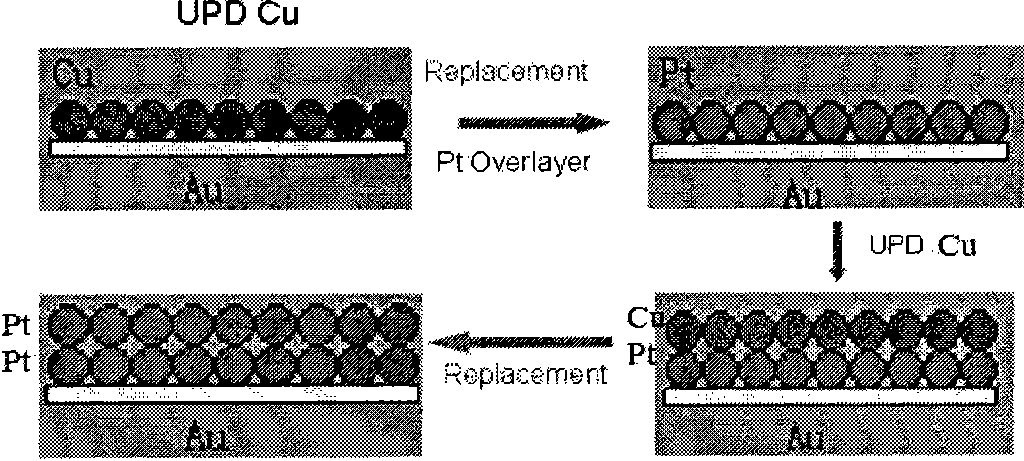

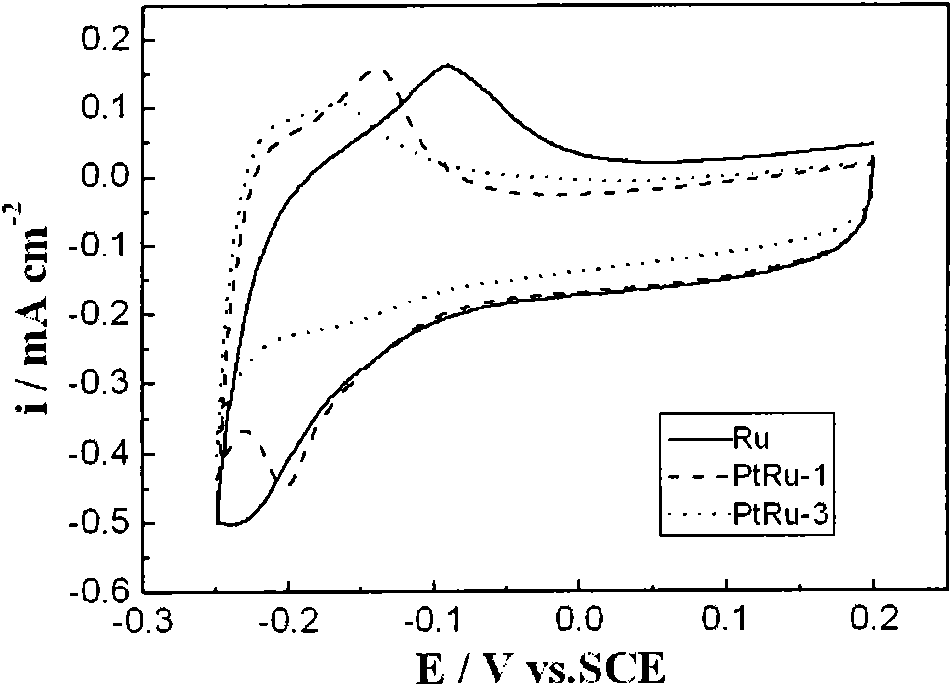

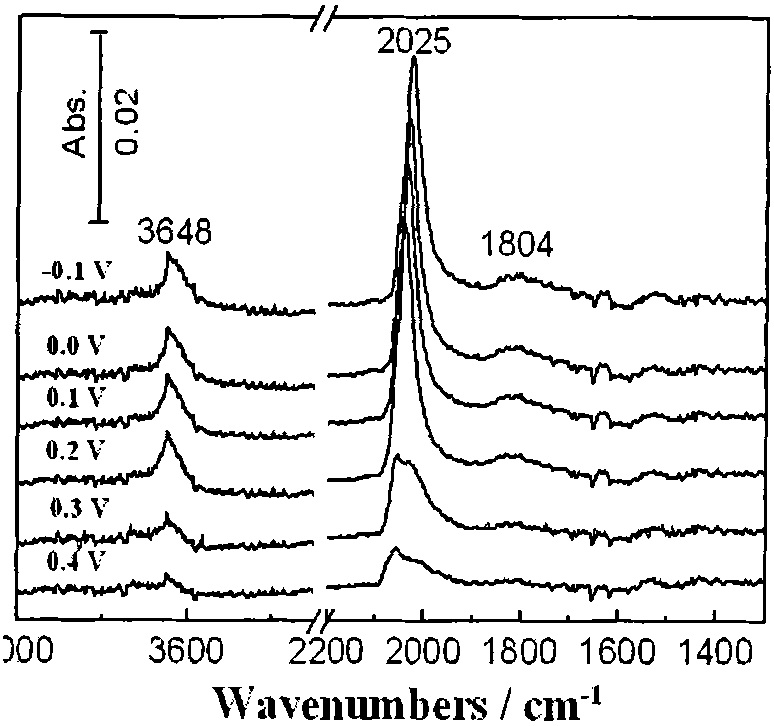

[0024] Preparation of a Ru-based / Pt skin nano-film working electrode

[0025] First, electroless gold plating is performed on the reflective bottom of the semicircular silicon column; a 5-6 nm thick Ru film can be electrodeposited on the gold substrate by a two-step wet method; Above 0.005M CuSO 4 +0.1M H 2 SO 4 Cu was underpotentially deposited at 0.025V saturated calomel electrode in the solution for 180s, and then rapidly added to 0.005M K 2 PtCl 4 +0.1MH 2 SO 4 Substitute Pt in the solution and let it stand for 10 minutes to make the replacement reaction complete.

[0026] PtRu binary nanofilm electrodes with different Pt loadings can be obtained through different underpotential deposition Cu-substitution cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com