Fuel filling device for vehicle fuel tank

一种燃料箱、供油口的技术,应用在供油口装置领域,能够解决开闭器困难、不现实等问题,达到提高交换性、抑制移动、防止对流的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

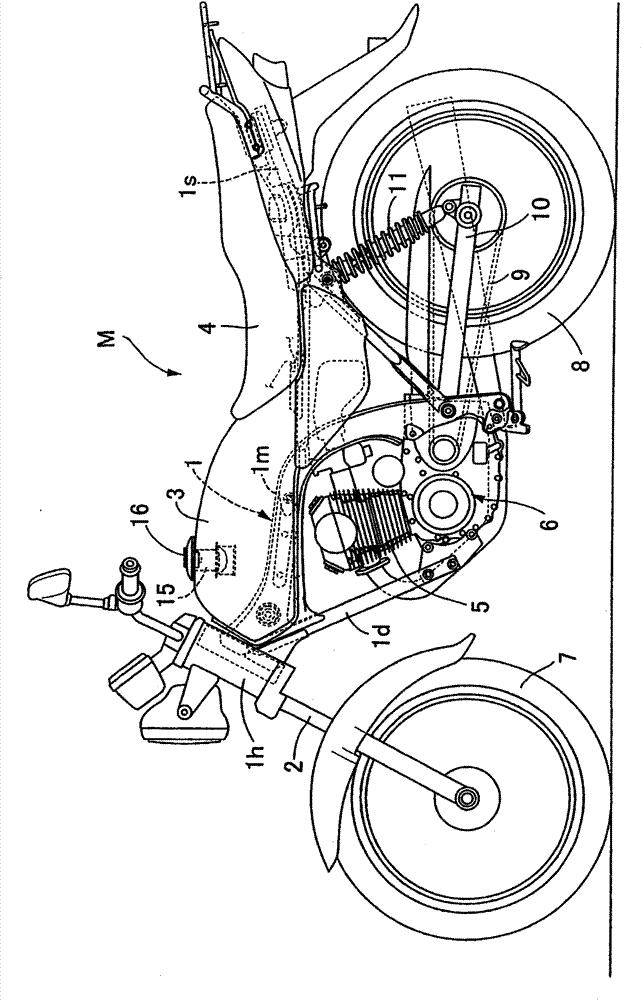

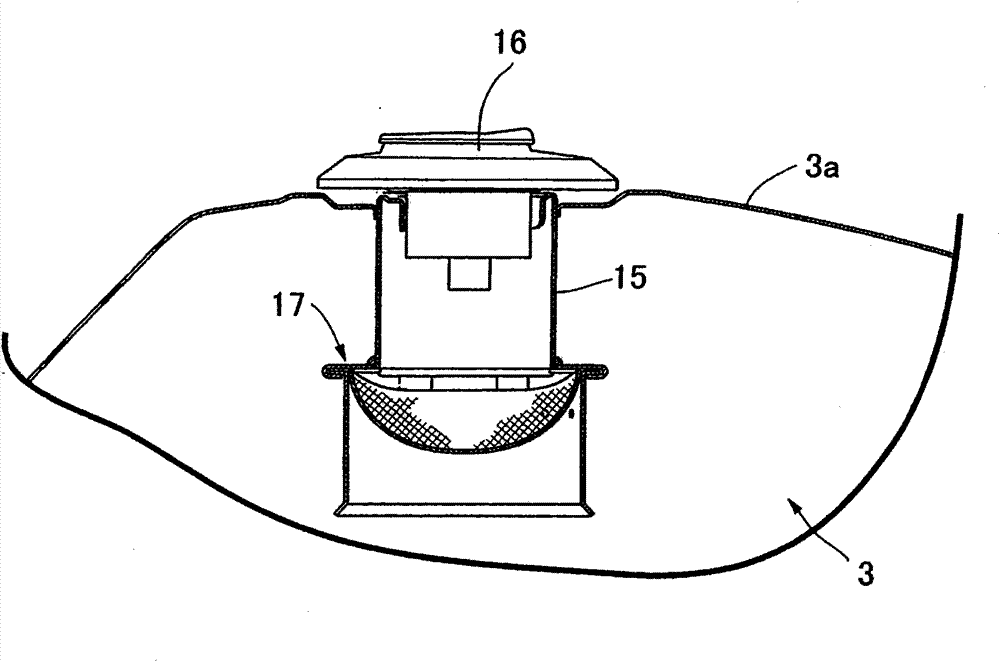

[0047] First, from Figure 1 ~ Figure 4 The description begins with the first embodiment of the present invention shown.

[0048] exist figure 1 Among them, a frame 1 of a motorcycle M includes: a head tube 1h that supports a front fork 2 in a direction that can be steered; The rear end of the horizontal part of the frame 1m extends substantially horizontally to the rear of the seat rail 1s, the frame lower tongue 1d extends obliquely downward from the head pipe 1h, and the fuel tank 3 is attached to the main frame 1m and connected behind it. The arranged seat 4 is attached to the seat rail 1s, and the power unit 6 including the engine 5 arranged directly below the fuel tank 3 is mounted between the lower tongue 1d of the frame and the lower curved portion of the main frame 1m. The front wheel 7 is pivotally supported on the lower end of the front fork 2, and the rear wheel 8 driven by the power unit 6 via the chain 9 is pivotally supported on the rear end of the rear fork 1...

Embodiment 2

[0069] Next, explain Figure 5 and Figure 6 Shown is the second embodiment of the present invention.

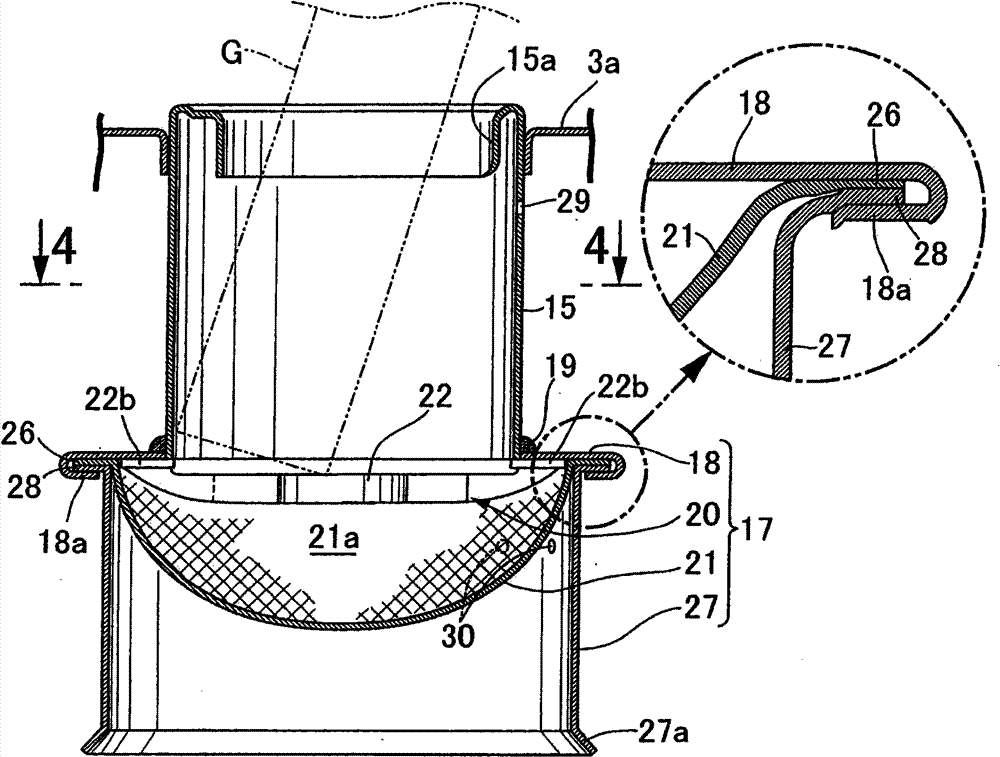

[0070] In this second embodiment, a pair of support pieces 22b, 22b are formed at both ends of the two plate members 22, 22 constituting the oil gun stopper 20, and the protrusions 24 of each plate member 22, 22 are , 24 are biased in opposite directions from the axis of the oil supply guide cylinder 15, so that the above two strip plate members 22, 22 are separated from each other, and the respective pair of supporting pieces 22b, 22b are welded to the lower surface of the mounting plate 18 On, other structures are the same as the previous embodiment, therefore, in Figure 5 and Figure 6 In , parts corresponding to those in the previous embodiments are denoted by the same reference numerals, and redundant descriptions are omitted.

[0071] According to this second embodiment, compared with the previous embodiments, although the number of supporting pieces 22b of the st...

Embodiment 3

[0073] Next, in Figure 7 and Figure 8 In the third embodiment of the present invention shown, a pair of two plate members 22, 22 constituting the oil gun stopper 20 of the first embodiment are formed along the inner peripheral surface of the oil supply guide cylinder 15. The supporting pieces 22b, 22b are welded and fixed on the lower inner peripheral surface of the oil supply guide cylinder 15. Other structures are the same as the first embodiment, therefore, in Figure 7 and Figure 8 In FIG. 1, the same reference numerals are assigned to the parts corresponding to those of the first embodiment, and overlapping descriptions will be omitted.

[0074] In the case of the third embodiment, the flame arrester assembly 17 is composed of three of the mounting plate 18 , the flame arrester 21 and the skirt 27 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com