Hydraulic classifier

A technology of hydraulic classifier and sorter, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of single flow state, instability, and small effective separation area in the separation area, and achieve guaranteed Grading accuracy and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

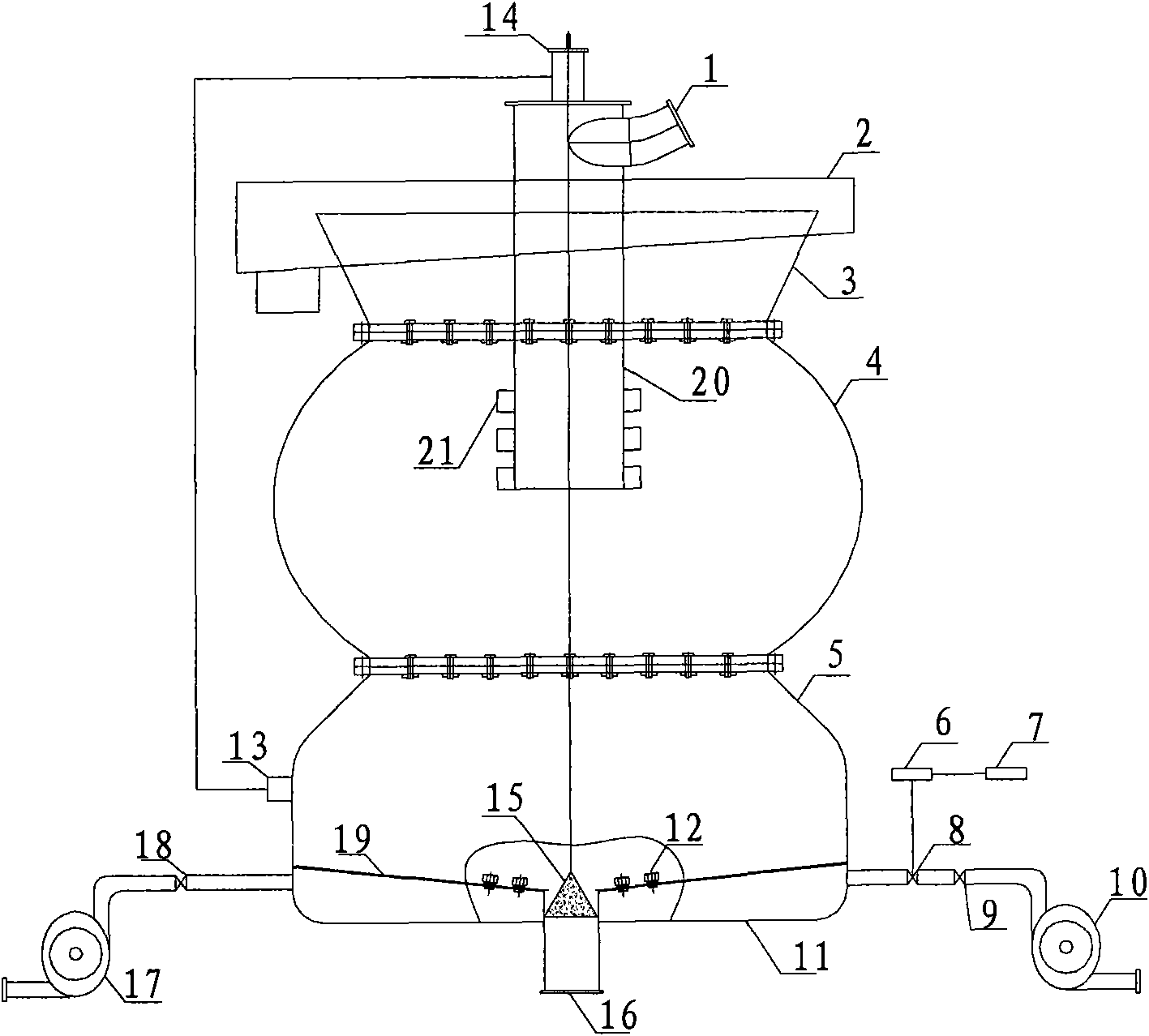

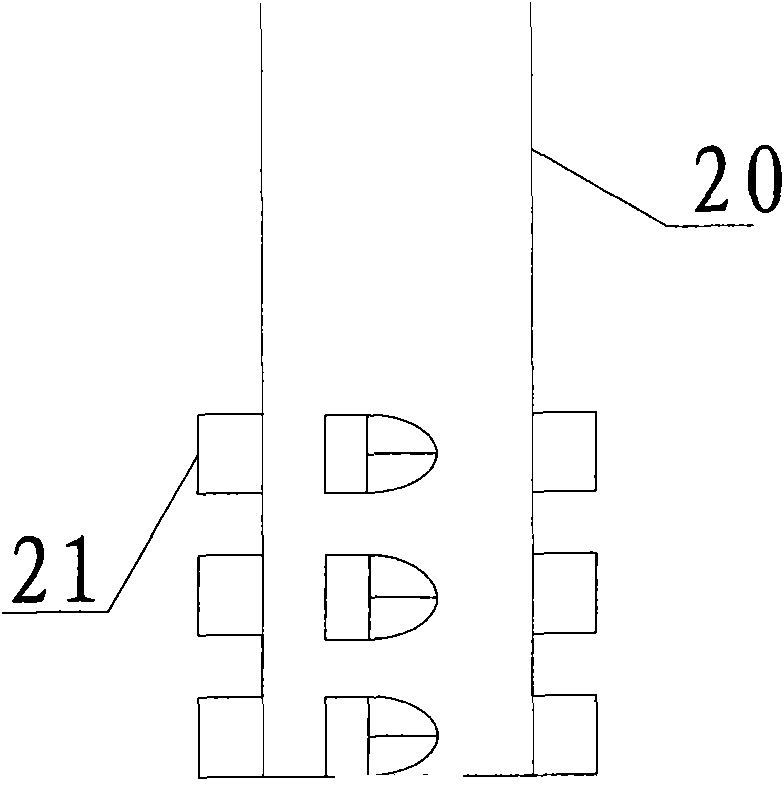

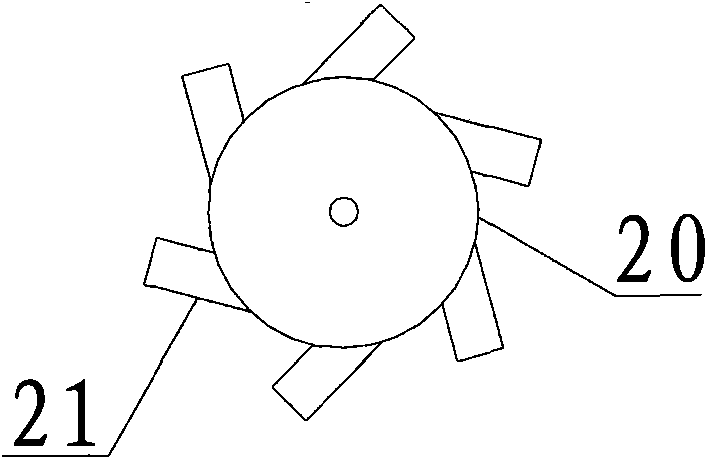

[0023] Such as figure 1 As shown, the hydraulic classifier of the present invention includes a classifier body with a card waist gourd-like structure consisting of an overflow collection section 3 at the top, a grading bed section 4 at the middle and an underflow collection section 5 at the bottom. And flange connection is adopted between each section, and the cross-sectional area of the overflow collection section 3 is an inverted conical structure gradually increasing from bottom to top; The way of the axis is installed in the hollow cavity of the main body of the sorting machine through a fixed connector, and the lower end of the feeding well 20 extends vertically downwards to the middle part of the cavity of the grading bed section 4, and the upper section of the feeding well 20 is as high as At the upper edge of the overflow collection section 3; at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com