Constant pressure type hydraulic distance-regulating device

A distance adjustment device and hydraulic technology, which is applied in the field of distance adjustment devices, can solve the problems of display scale deviation, affecting work continuity, and large mechanical transmission inertia, so as to eliminate the influence of distance adjustment accuracy, ensure work continuity, and realize accurate The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

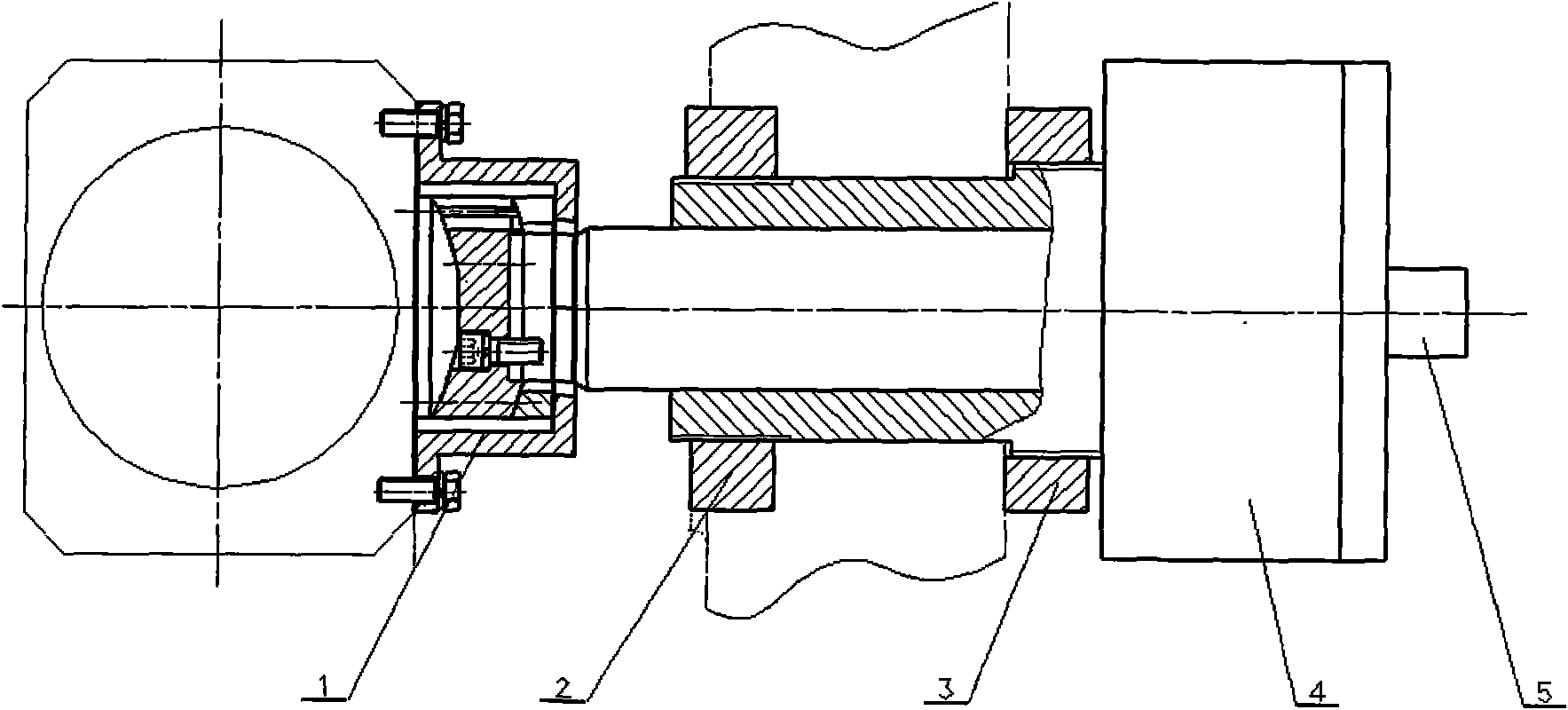

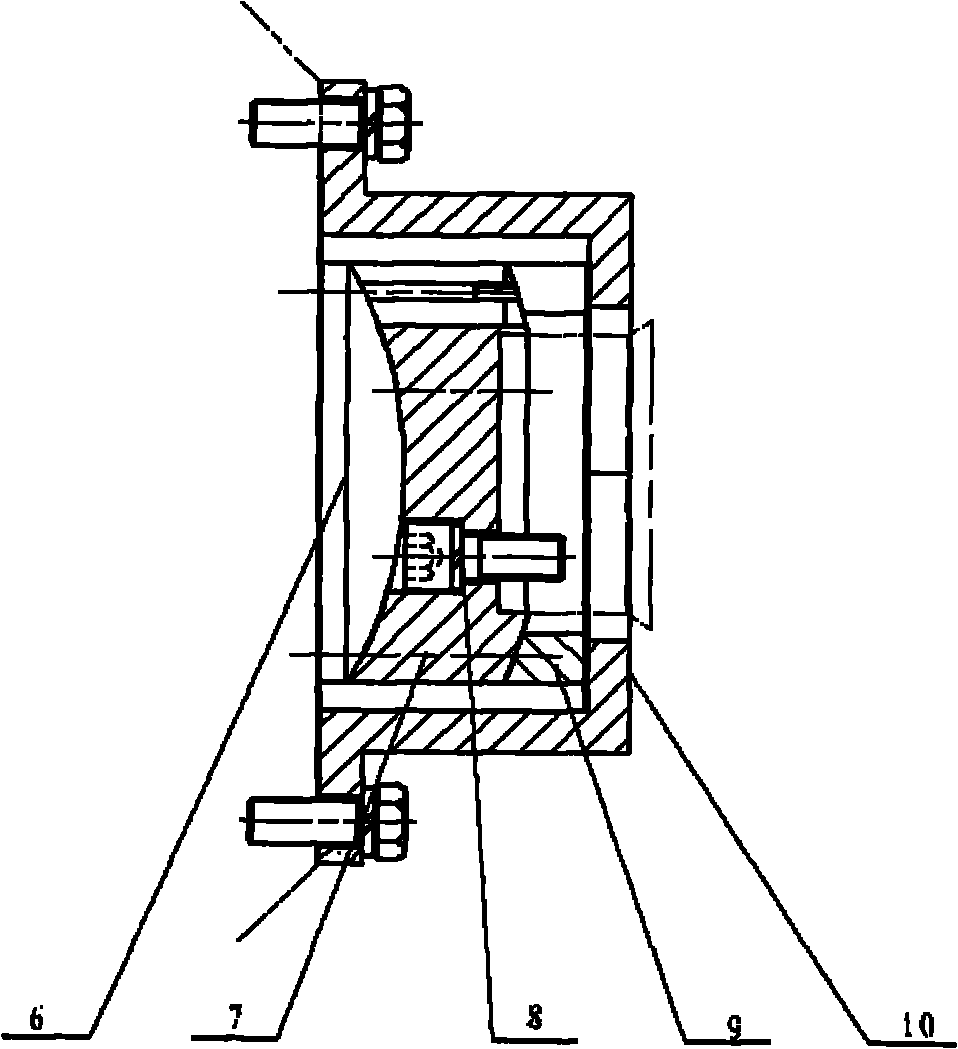

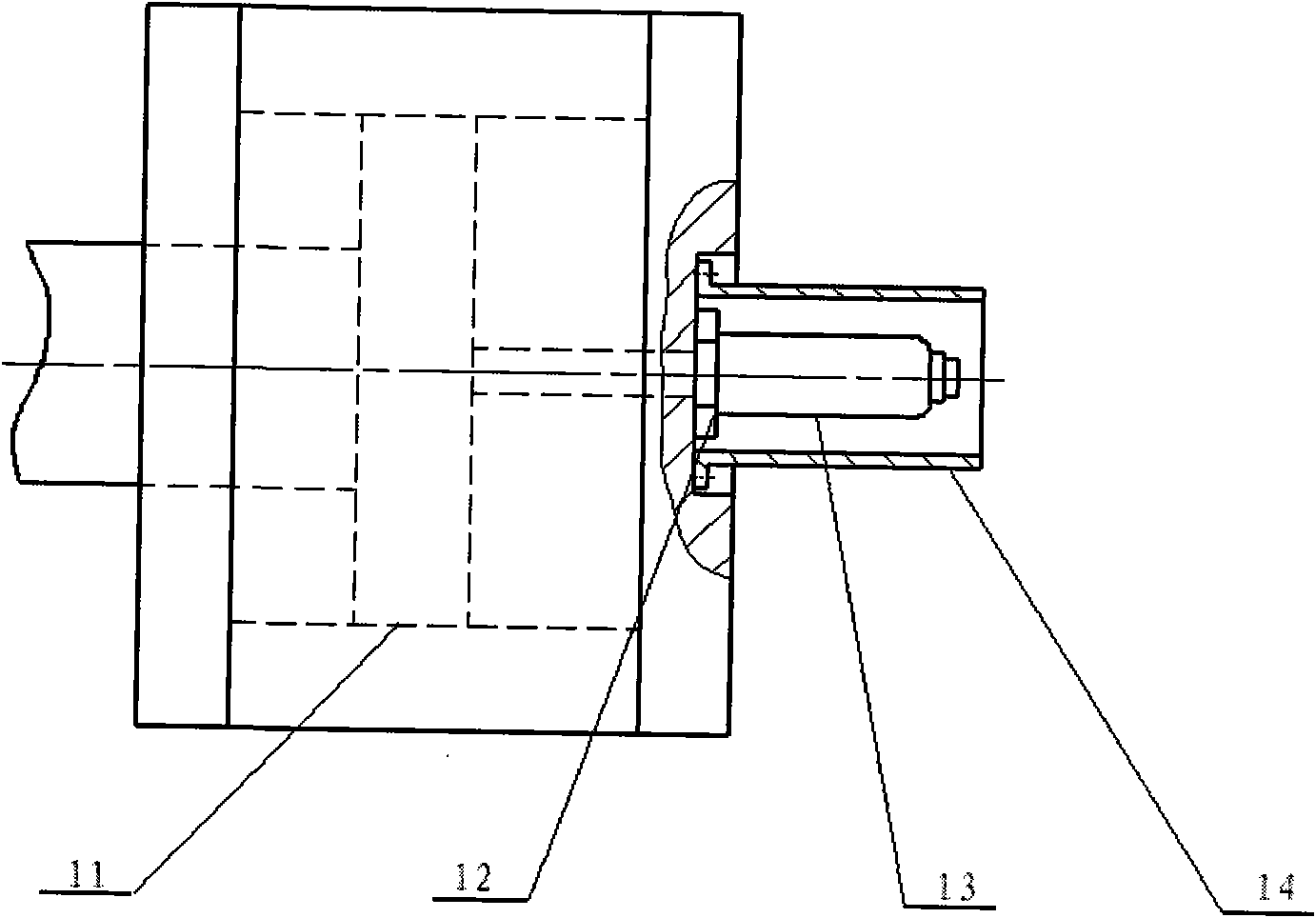

[0028] The specific implementation is as figure 1 Shown:

[0029] 1. Working process of voltage stabilization: After the low-pressure start of the oil pump, the oil pump supplies oil to the rodless cavity, and the roller moves quickly to the target roller distance δ. After a certain distance from the target roller distance δ, it changes to a slow forward movement and advances in parallel to δ- After 0.1mm, switch the solenoid valve to fill the rod cavity of the cylinder with oil and return the cylinder to the target roller pitch δ+0.1mm, then pressurize the two cylinders alternately to the rated pressure and maintain it, and then normal rubber mixing can be performed ; When the oil cylinder loses pressure during the working process, open the control valve for charging; when the roller is offset back and forth, repeat the above process to re-establish the pressure. The whole process is automatically completed by the signal feedback of displacement and pressure and the control prog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com