Method and system for transferring push rod chain and friction chain

A technology of hanging and pushing rods, which is applied in transportation and packaging, conveyor control devices, conveyor objects, etc., can solve the problems of easy loss of accurate control signals, difficult position of spreaders, failures, etc., and saves maintenance costs and energy. , The effect of reducing major losses and preventing equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

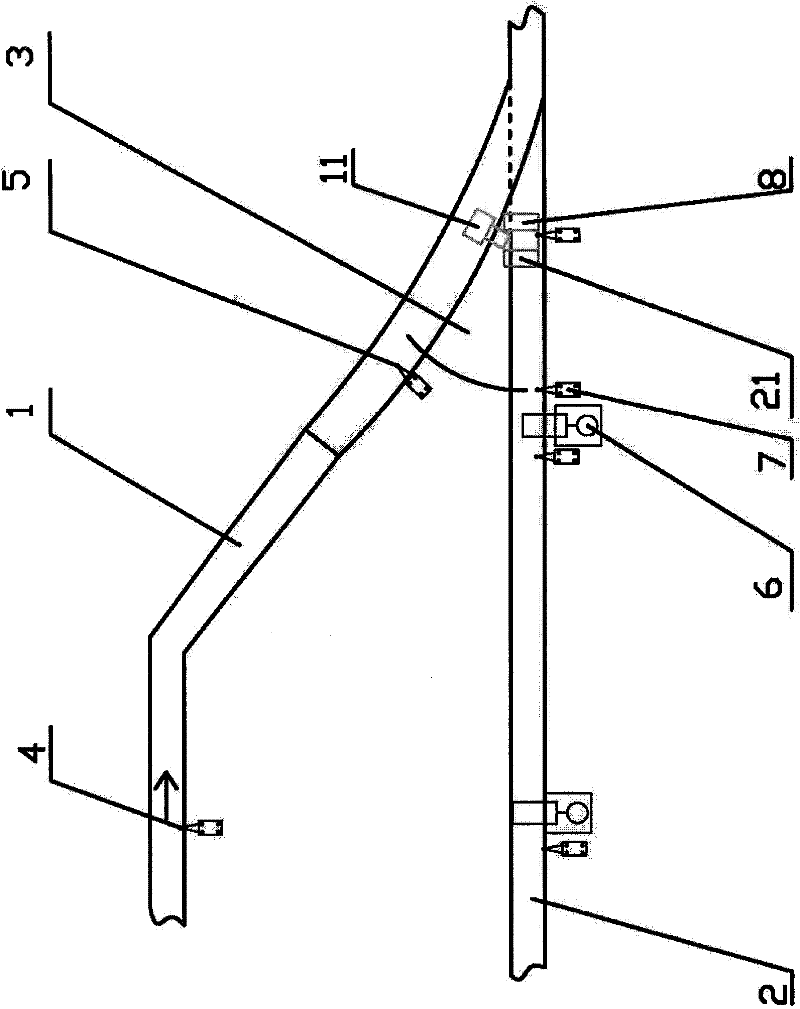

Embodiment 1

[0035] The first embodiment of the present invention proposes a push rod chain and friction chain transfer system, its structure is as follows figure 2 As shown, it includes: a spreader track 2 and a spreader 21 moving along the spreader track 2; and a pusher track 1 and a pusher 11 moving along the pusher track 1; The push head rails 1 meet and form a transfer area 3; the spreader track 2 is provided with a stop position 8 in the transfer area 3, and the spreader 21 is connected to the push head at the stop position 8. 11 meshing; the spreader track 2 is provided with a stopper 7 for fixing the spreader 21, and the stopper 7 is separated from the stop position 8 by a preset distance;

[0036] Also includes:

[0037] A primary push head detection module 10, the primary push head detection module 10 is placed on the push head track 1, and is separated from the hanging area 3 by a preset distance;

[0038] The secondary push head detection module 5 is arranged on the push hea...

Embodiment 2

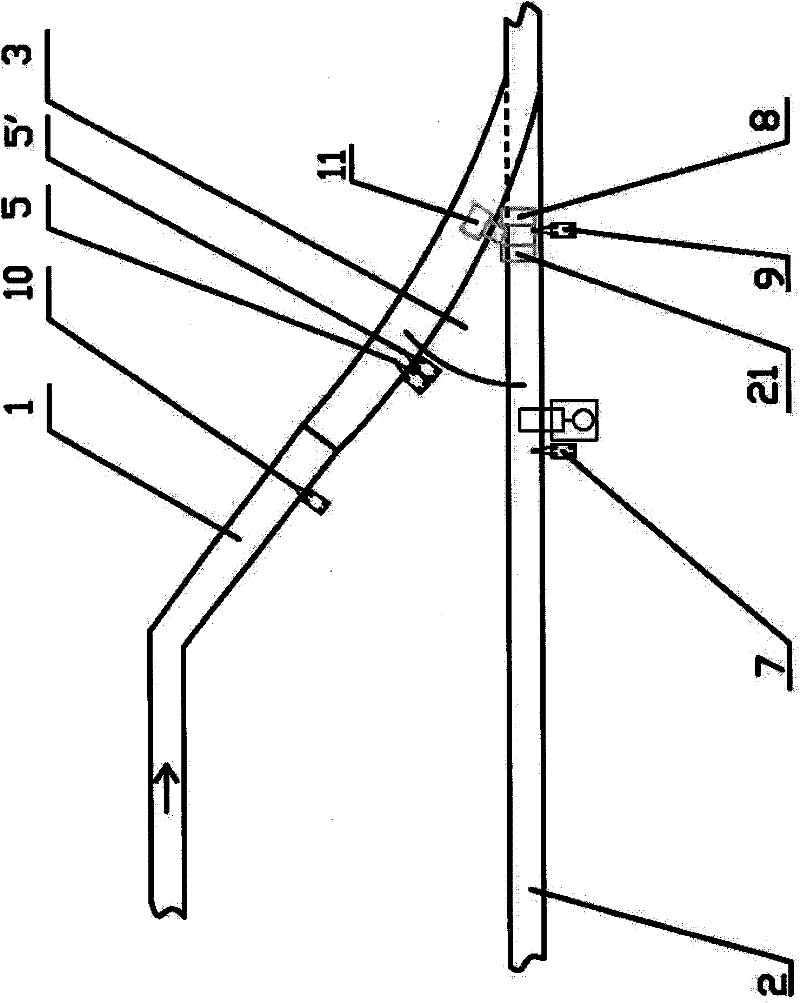

[0044] The second embodiment of the present invention proposes a push rod chain and friction chain transfer system, its structure is as follows figure 2 As shown, it is improved on the basis of the first embodiment of the present invention. That is, in the technical solution of the first embodiment, it also includes:

[0045] Further, the distance between the primary push detection module 10 and the secondary push test module 5 is not greater than the distance between the stopper 7 and the stop position 8 . This can ensure that the spreader passes the stopper when a push head detection module detects a push head. Because the distance between the primary push detection module and the secondary push test module is not greater than the distance between the stopper and the stop position. Since the travel speed of the spreader will be slightly greater than that of the push head in actual use, this can ensure that the spreader has reached the stop position when the push head reac...

Embodiment 3

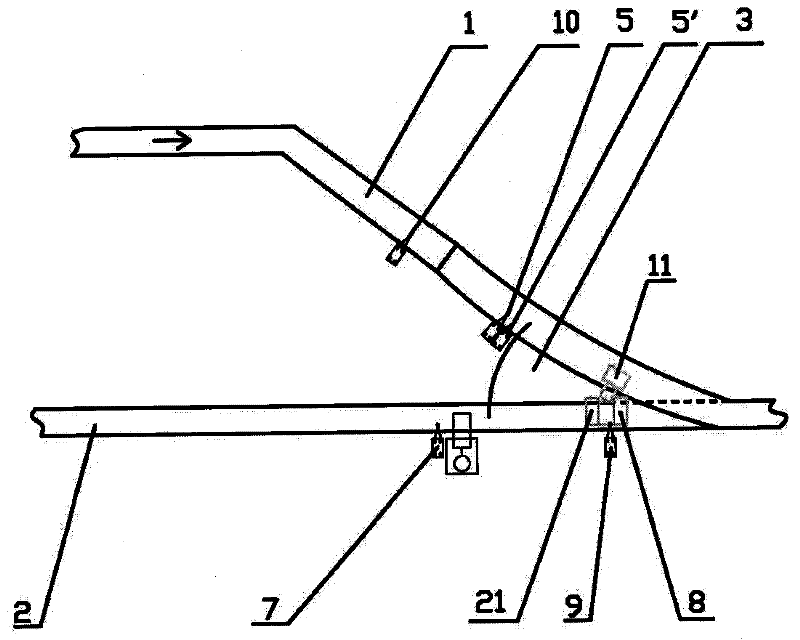

[0051] The third embodiment of the present invention also proposes a method of using the push rod chain and the friction chain transfer system of the first and second embodiments to carry out the hanging method, refer to figure 2 As shown in the system, the method of this embodiment includes:

[0052] When the primary push head detection module 10 detects that the push head 11 passes by, it sends a signal to the control module:

[0053] The control module controls the stopper 7 to open, so that the spreader 21 passes;

[0054] When the spreader detection module 9 detects that the spreader 21 is located at the stop position 8, it sends a first notification signal to the control module;

[0055] When the secondary push head detection module 5 detects that the push head 11 passes by, send a second notification signal to the control module;

[0056] When the control module receives the second notification signal, it judges whether the first notification information has been rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com