Bearing gear unit for paper maker or carton machine

A transmission unit and bearing technology, applied in paper machine, paper, textile and paper making, etc., can solve the problems of complicated, complicated and expensive removal of gears, reduce the number of pipes, reduce maintenance intensity, reduce bearing detection and Effects of Lubrication Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

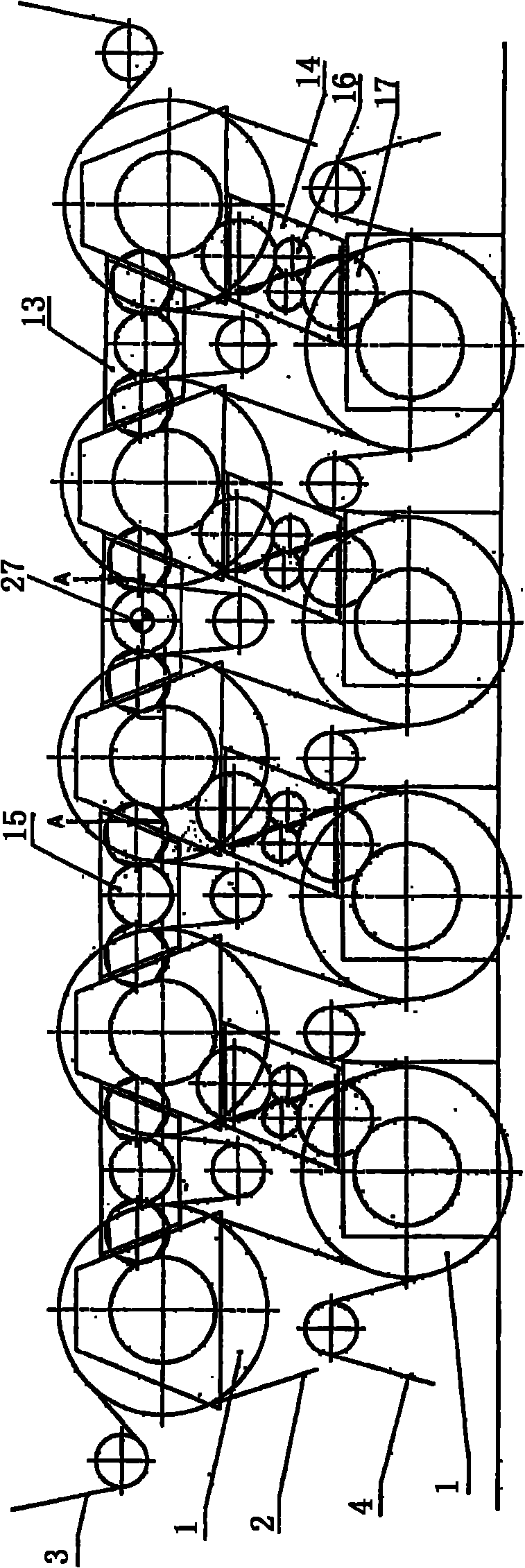

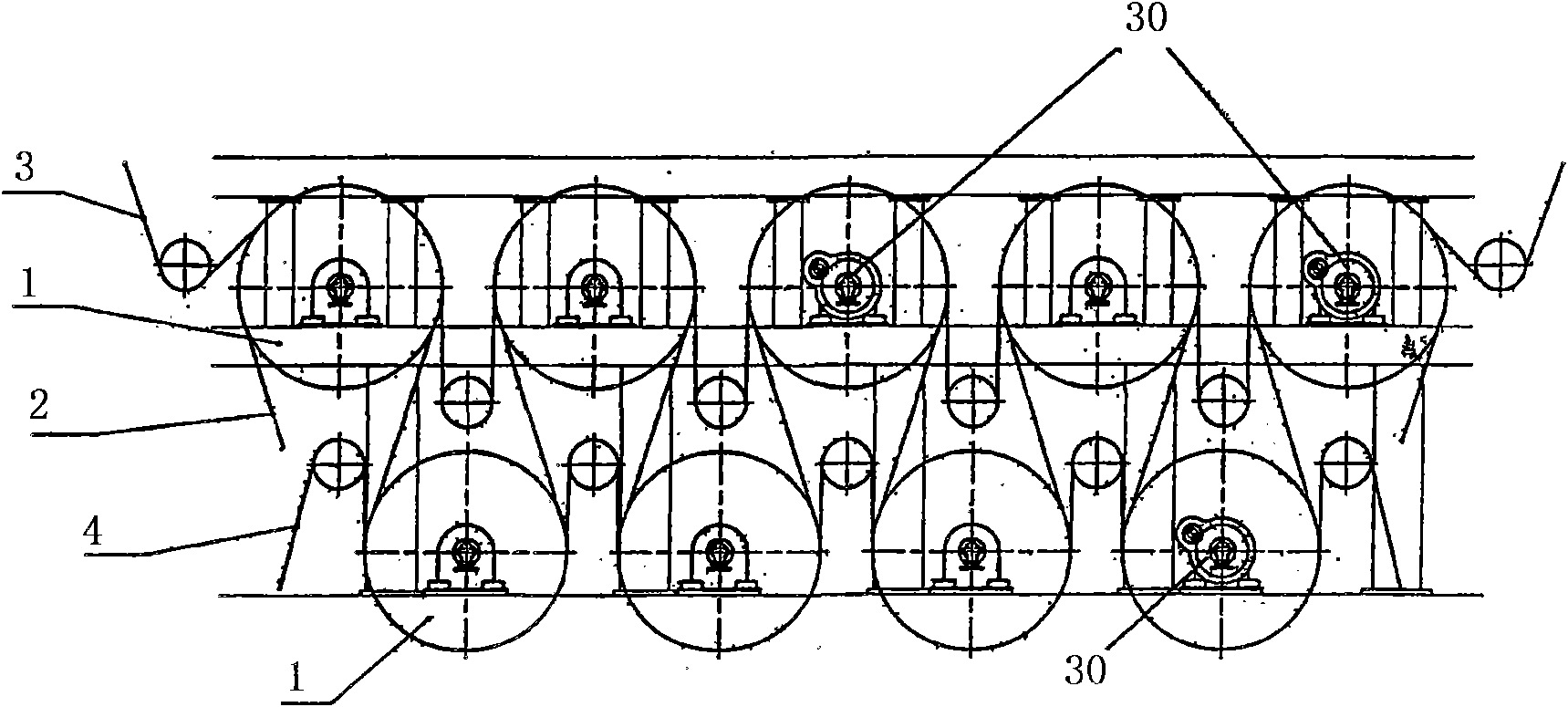

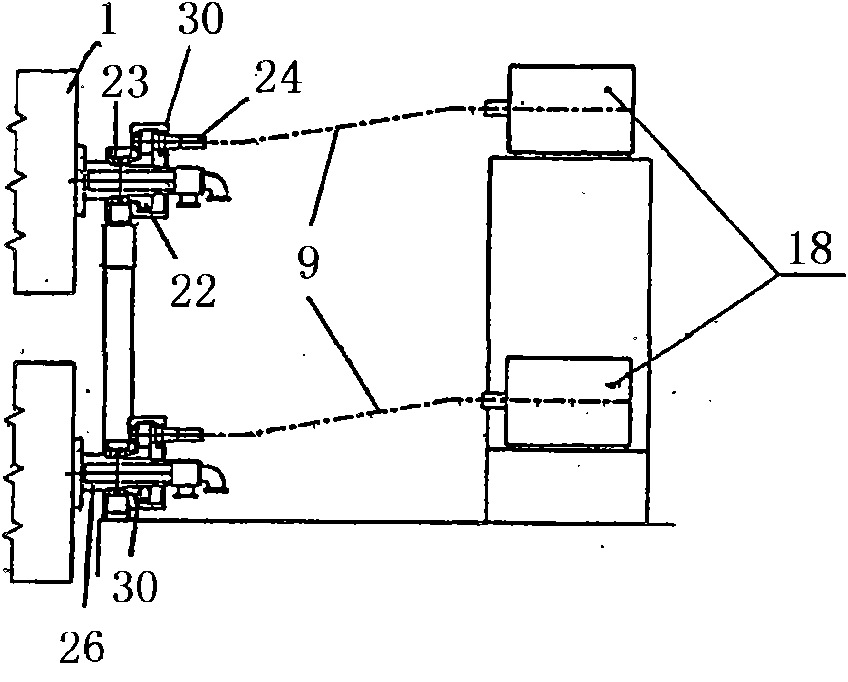

[0032] figure 1 A drying group of dryer components in the prior art is shown. Here, the paper web 2 is guided along a tortuous path past the drying cylinder 1 , which is pressurized from the inside with steam so that the cylinder shell is heated. In this process, the wet paper web 2 wrapped around the drying cylinder 1 is dried as quickly as possible, in which condensation water forms, which is drained off through holes drilled in the journal. The drying cylinder 1 is arranged in two layers, and the bottom row can also be replaced by suction rollers.

[0033] The paper web 2 is pressed against the surface of the drying cylinder by the wires 3, 4 to achieve the best possible contact and thus the best drying efficiency.

[0034] exist figure 1 In order to drive all the drying cylinders 1 and connect them to each other, a horizontal gearbox 13 or a vertical gearbox 14 is used. These gearboxes 13, 14 house a corresponding number of so-called intermediate gears 15, 16, 17 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com