Egg shape conical gear pump

A bevel gear and oval technology, which is applied in the field of oval bevel gear pumps, can solve the problems of increasing the volume and speed of the gear pump, affecting the pump efficiency, and loud noise, so as to overcome the large radial force, save driving energy, Good transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

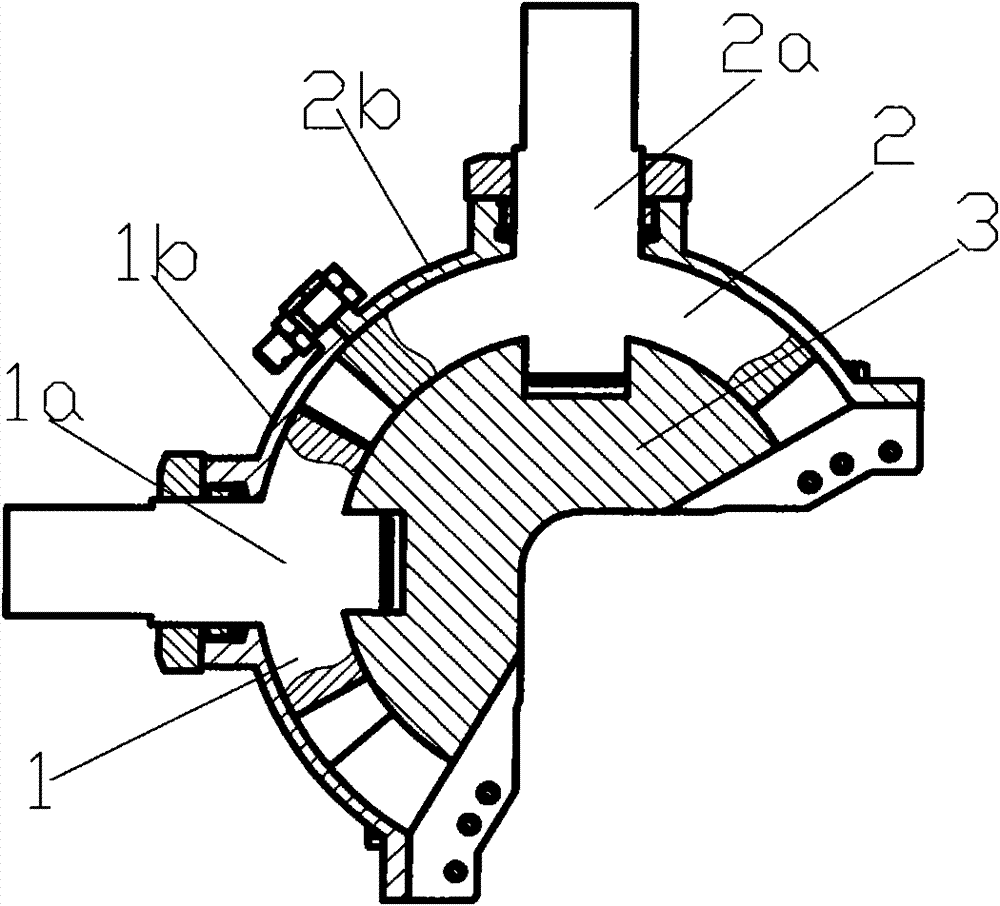

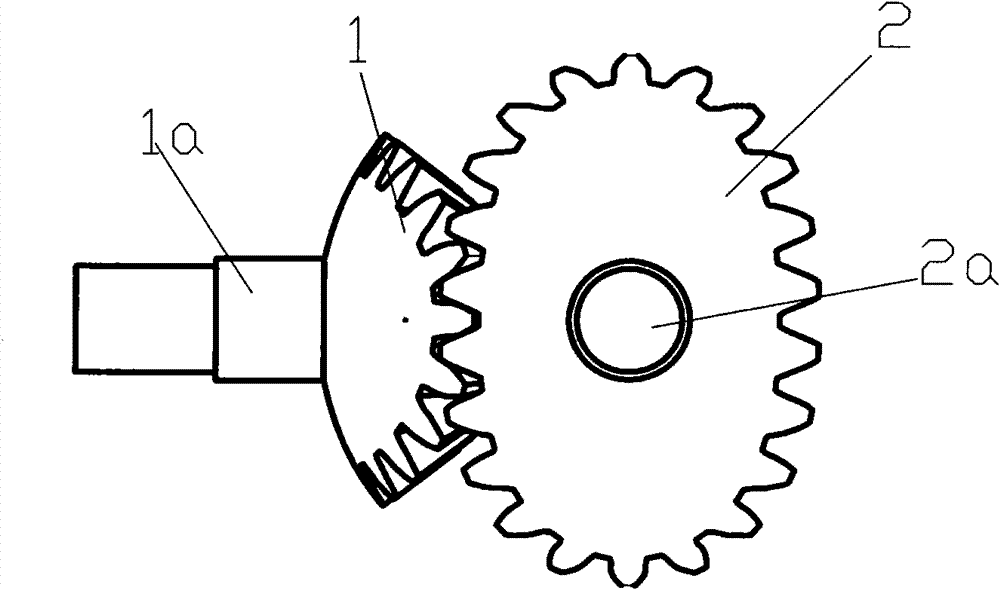

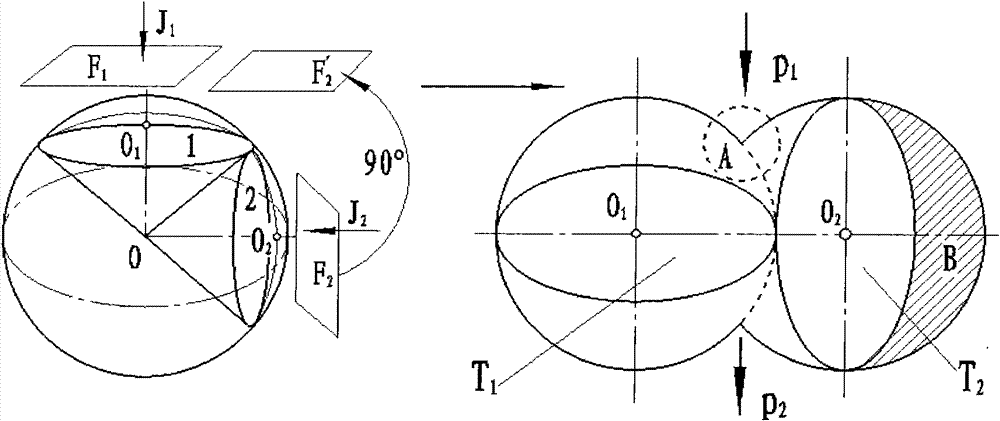

[0018] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the gear meshing structure of the present invention, as shown in the figure: the oval bevel gear pump of this embodiment includes a pump casing, a driving gear and a driven gear arranged in the pump casing to mesh with each other, the driving gear 1 and the driven gear The gears 2 are all oval bevel gears and the axes are vertically intersected and meshed. The transmission ratio of the driving gear and the driven gear is: The pitch curve of the spherical large end face of the driving gear is oval, and the equation is: The pitch curve of the spherical large end surface of the driven gear is also oval, and the equation is In the equation, R is the spherical radius, k is the eccentricity, φ 1 is the rotation angle of the driving gear.

[0019] In this embodiment, the pump casing includes a pump bottom 3 and a top cover, the inner surface of the pump b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com