LED light mixing device

A light mixing device and LED light source technology, which is applied to lighting devices, components of lighting devices, optics, etc., can solve the problems of large thickness of the light mixing device, non-compliance with thinning, and low light output rate, so as to improve the light output rate, The effect of reducing thickness and uniform light mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The substantive features of the present invention will be further described below in conjunction with the drawings and specific implementations of the specification.

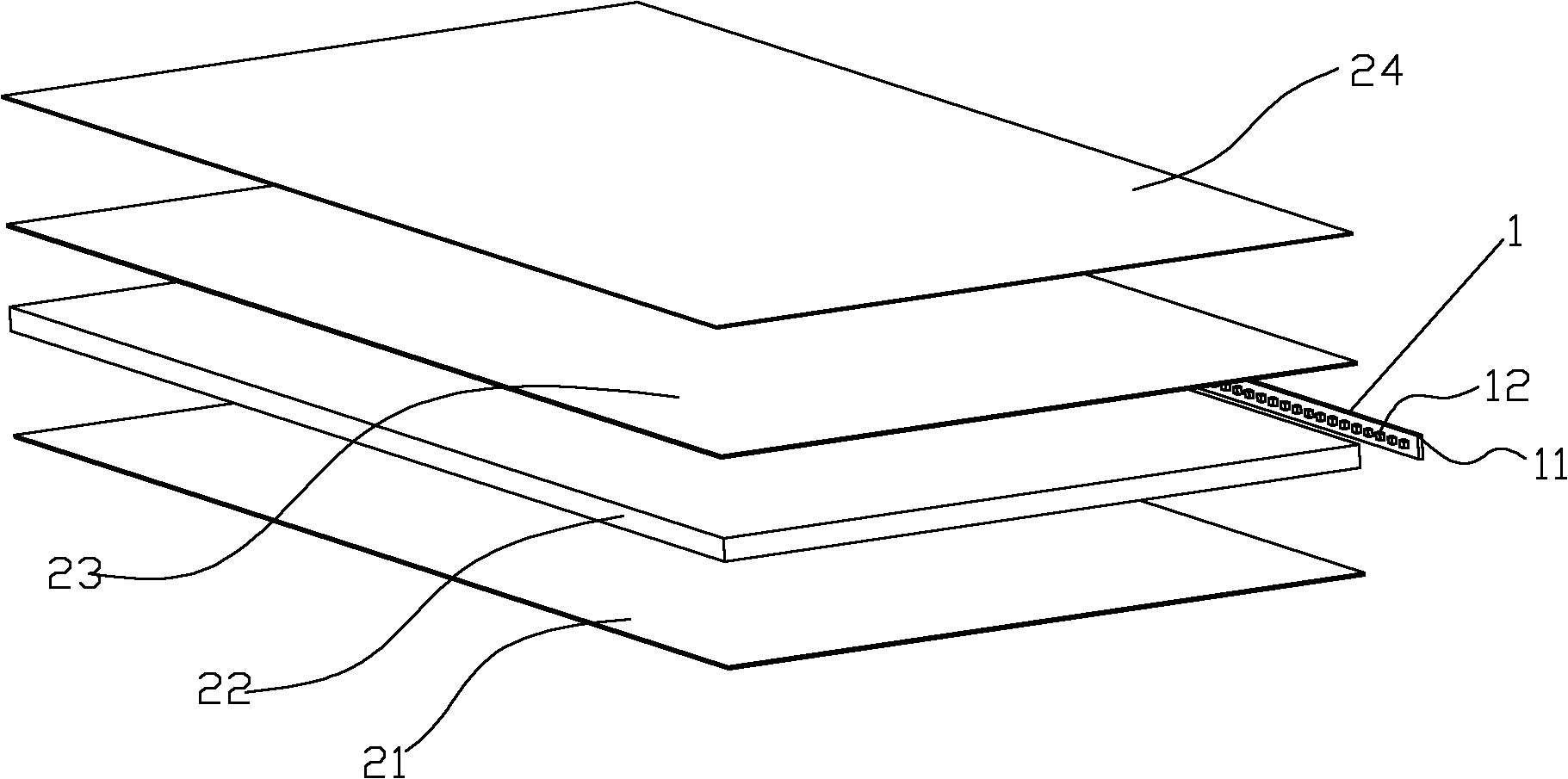

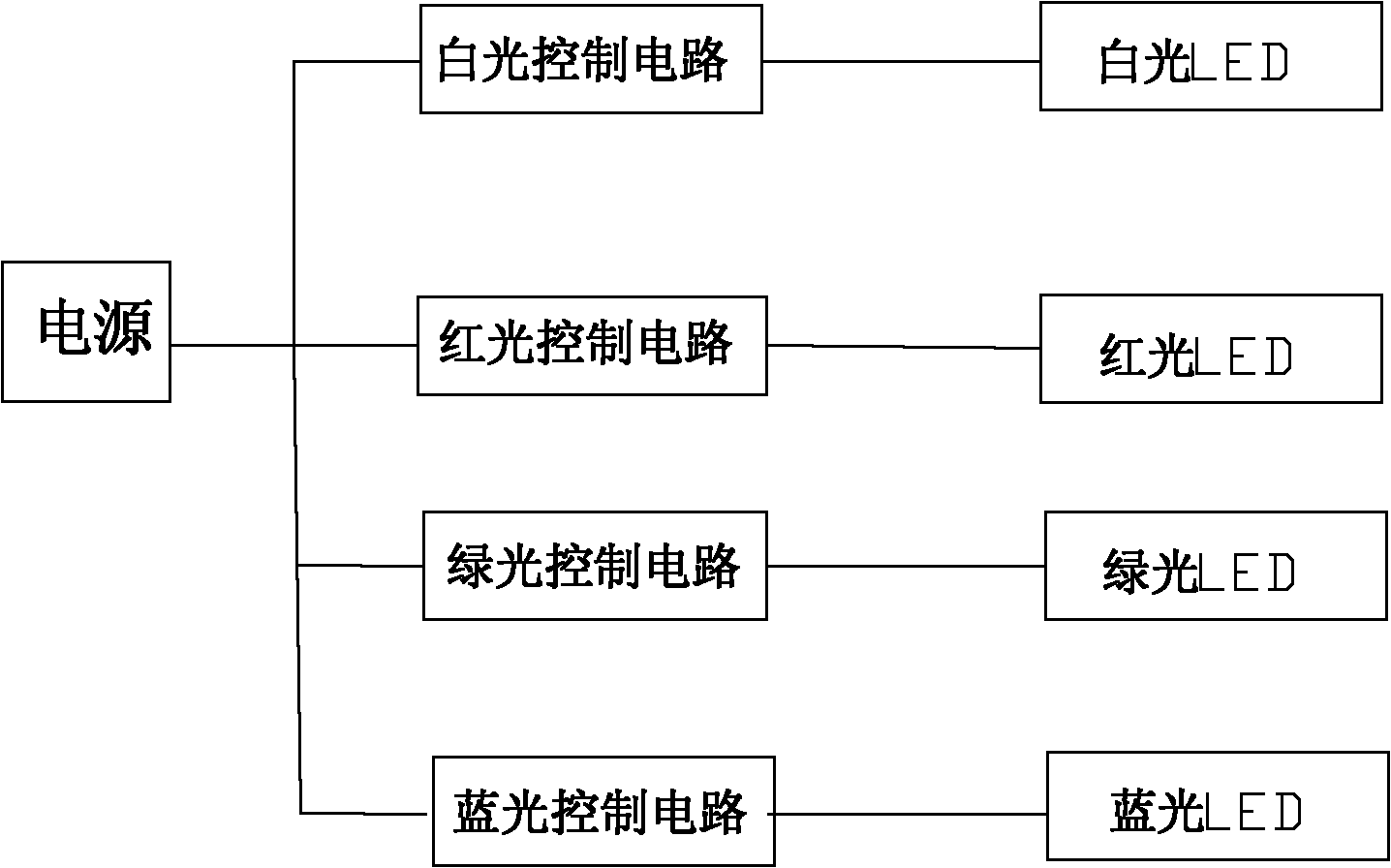

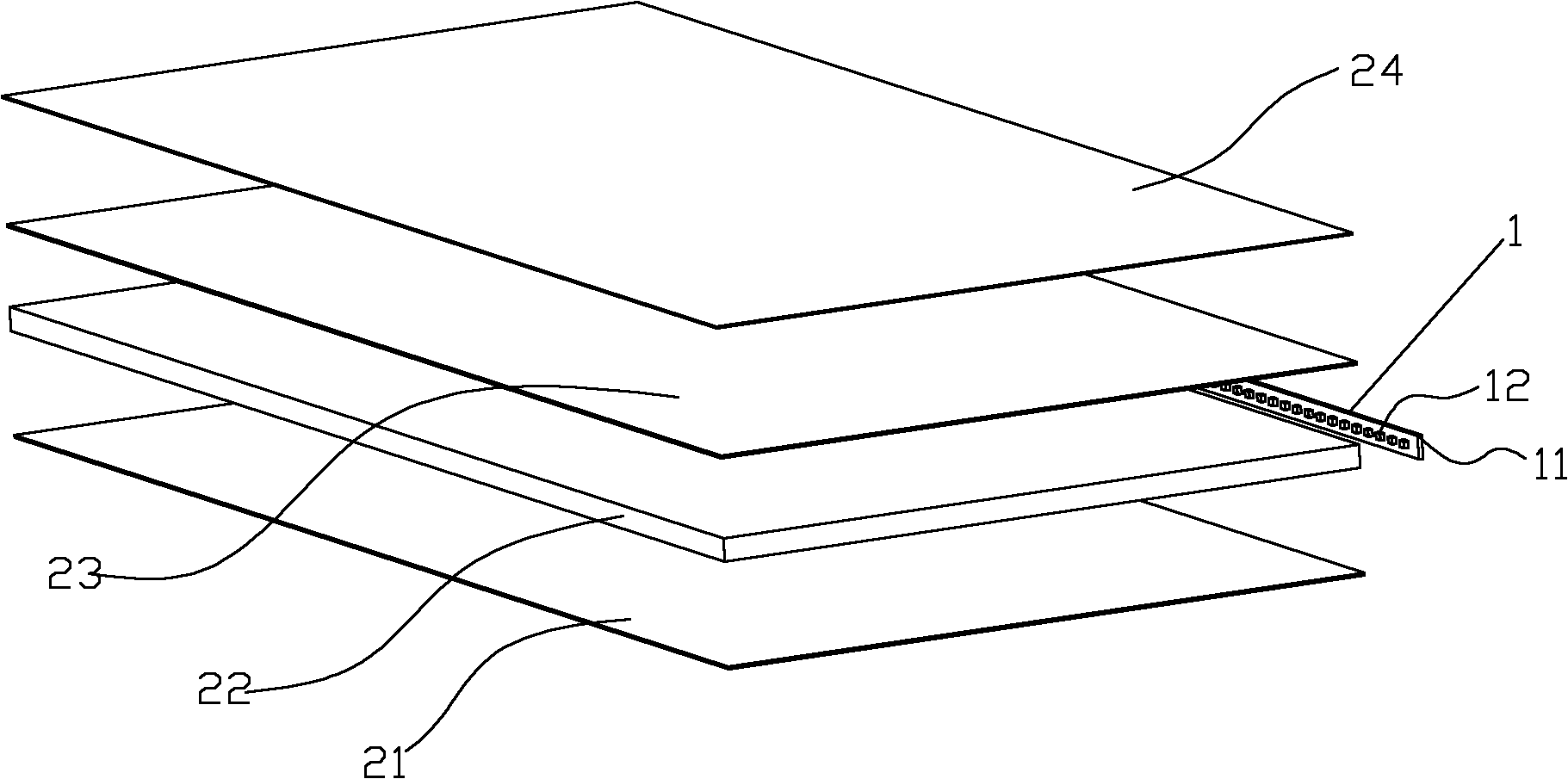

[0018] Such as figure 1 with figure 2 The LED light mixing device shown includes a rectangular parallelepiped light guide plate 22 made of materials such as PMMA, COP, or PC. The lower plate of the light guide plate 22 is formed with uniform scores or reflective dots. A light-emitting module 1 is provided on at least one side of the light guide plate 22. The light-emitting module 1 includes a long substrate 11 on which at least two monochromatic LED light sources 12 are mounted. A diffusion film 23 is provided above the upper panel of the light guide plate 22. The diffusion film 23 A light-transmitting plate 24 is provided above. A reflective sheet 21 is arranged under the lower panel of the light guide plate 22, and the reflective sheet 21 is made of PET or a material with a highly reflective coating on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com