Single optical frequency comb with high stability and high repetition frequency

A high repetition rate, optical frequency comb technology, applied in the field of femtosecond lasers, can solve technical difficulties and unseen problems, achieve high output power, long locking time, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

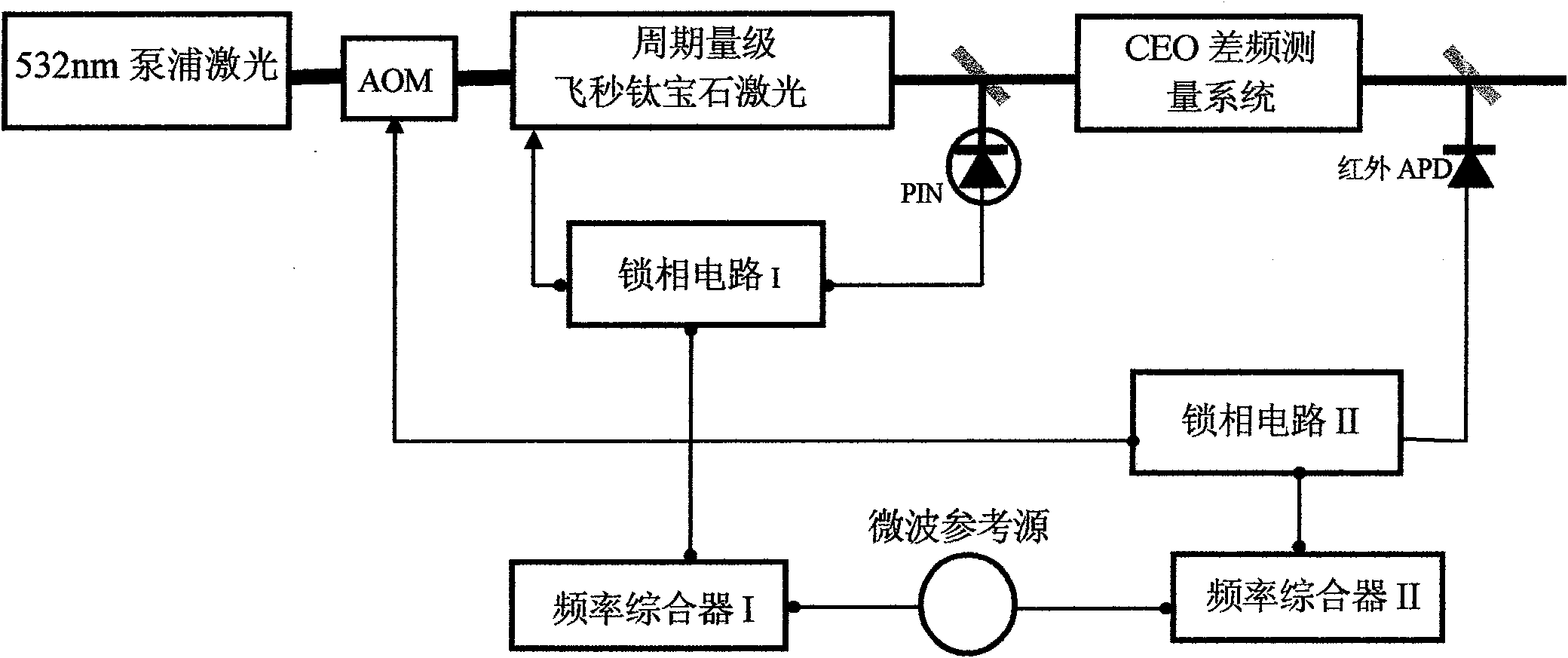

[0028] figure 1 It is a block diagram of the principle of the present invention.

[0029] like figure 1As shown, a 532nm single-frequency continuous full-curing frequency-doubling yttrium vanadate laser is used as the pump source. The pump light passes through the AOM and enters a period-scale Ti:sapphire oscillator, and then the femtosecond pulse output by the oscillator is divided into a small part by The PIN tube receives the repetition frequency signal, and most of it enters the difference frequency crystal to measure the CEO frequency. The optical pulse after the difference frequency measurement system is divided into two parts. The infrared light is received by the infrared APD to obtain the CEO frequency signal, and the visible light part is used as the available light of the optical comb. pulse output. Finally, in order to obtain an absolutely stable optical comb output, the repetition frequency received by the PIN and the CEO frequency electrical signal received by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com