Automatic electric connector assembling method and automatic electric connector assembler

An electrical connector and automatic assembly technology, which is applied in the field of automatic assembly machines, can solve the problems of low production efficiency, high production cost, and low degree of automation, and achieve the effects of improving productivity, flexible and convenient production and use, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

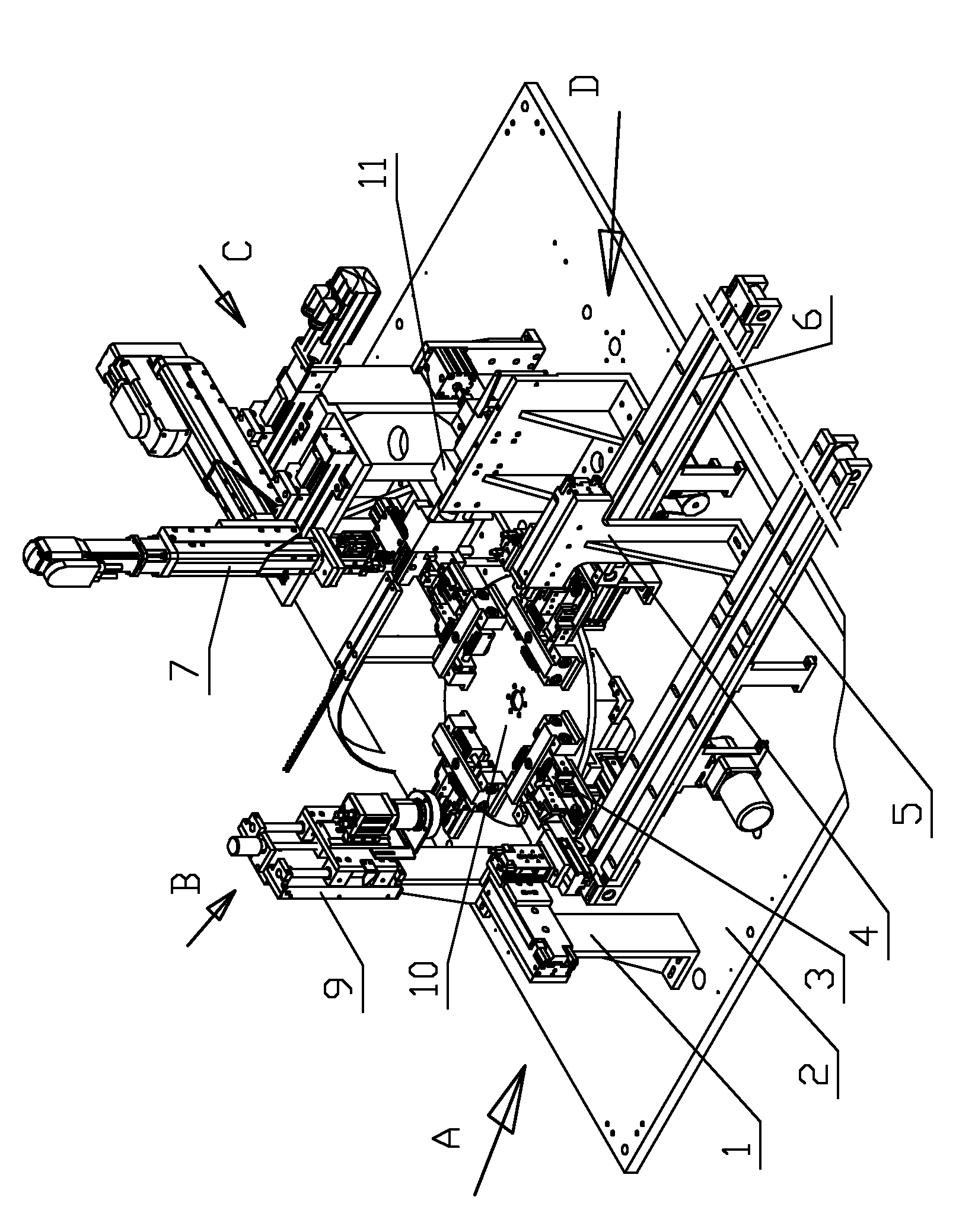

[0027] A preferred embodiment of the electrical connector automatic assembly method provided by the present invention is as follows:

[0028] A method for automatic assembly of electrical connectors, comprising steps in the following order:

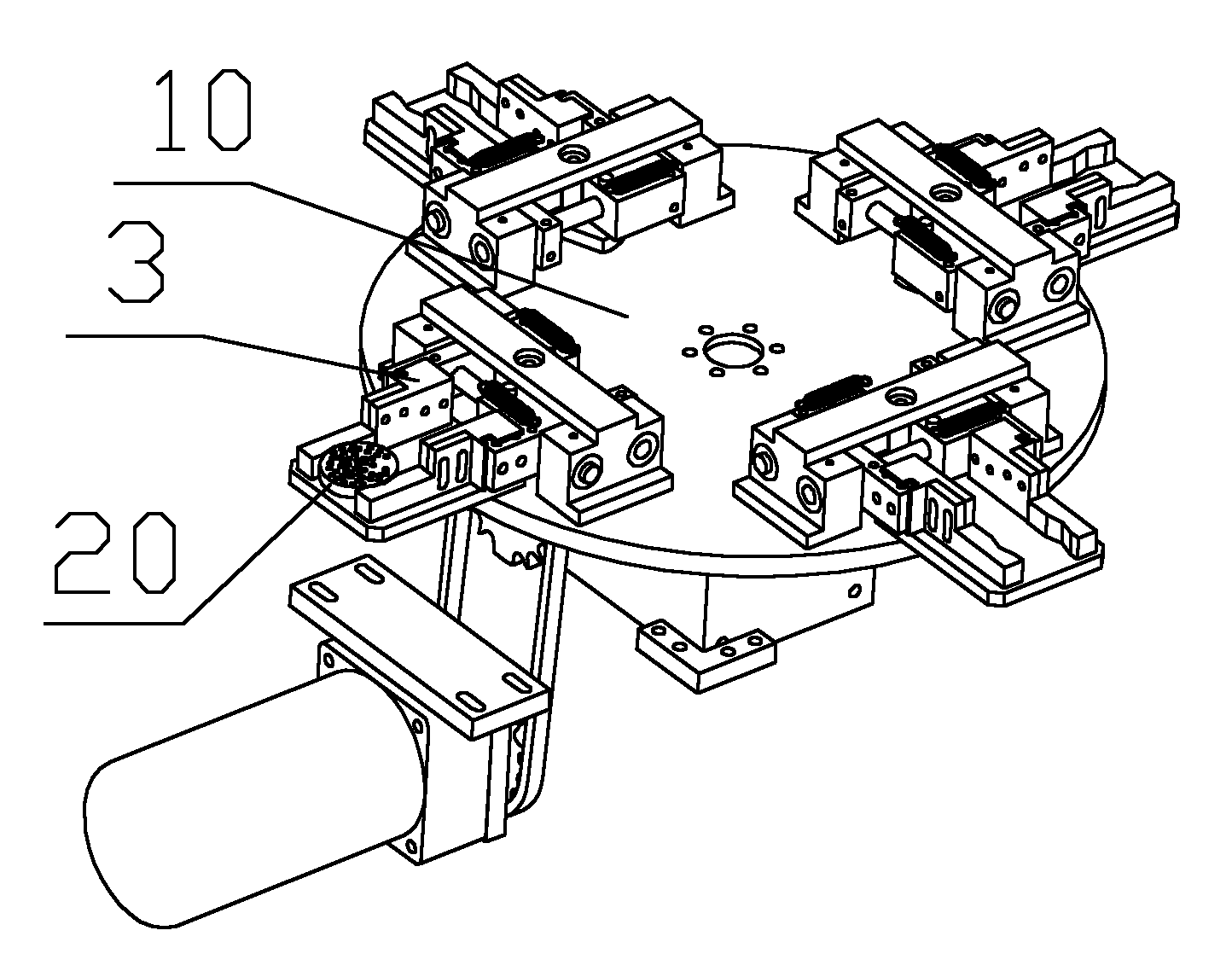

[0029] (1) An indexing turntable is set horizontally. Along the circumferential direction of the indexing turntable, there are loading stations, image detection stations, inserting stations and unloading stations in sequence. The indexing turntable corresponds to each station. The fixtures for clamping the parts with holes are arranged in turn, and the imaging device of the image detection system is correspondingly installed on the image detection station;

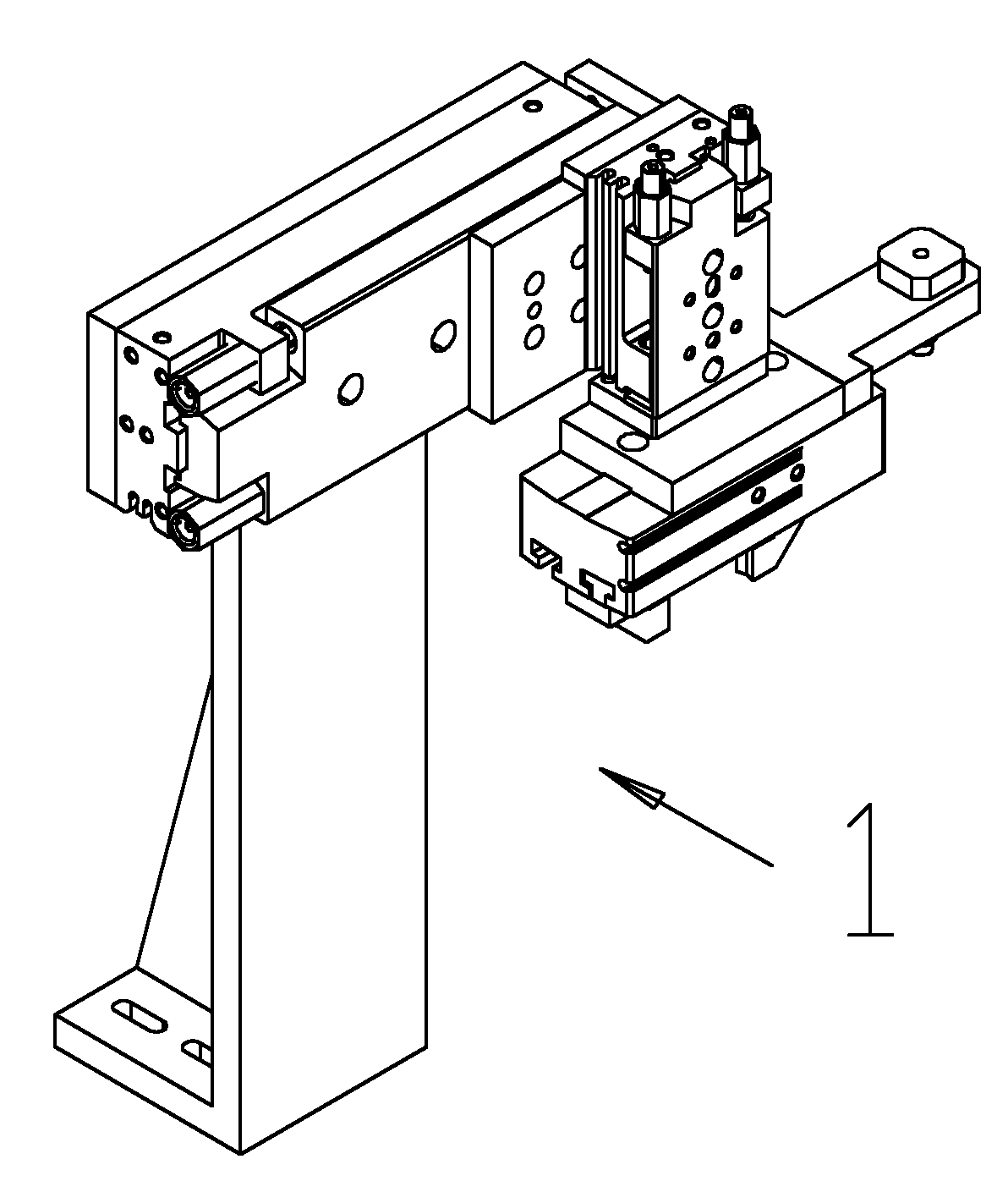

[0030] (2) Feeding: At the feeding station, the correspondingly set feeding manipulator grabs the parts with holes and moves them to the fixture on the indexing turntable at this station, and the parts with holes are clamped by the fixtures;

[0031] (3) Acquire image information and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com