Apparatus and method for treatment of pulp

一种纸浆、测量装置的技术,应用在化学仪器和方法、分离方法、洗涤/置换纸浆处理液等方向,能够解决更换测力计、密封件易受磨蚀磨损和其它应力、无法确定占优势等问题,达到成本低廉、减少过载的风险、少空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the figures, the same reference numerals are used for similar or corresponding parts.

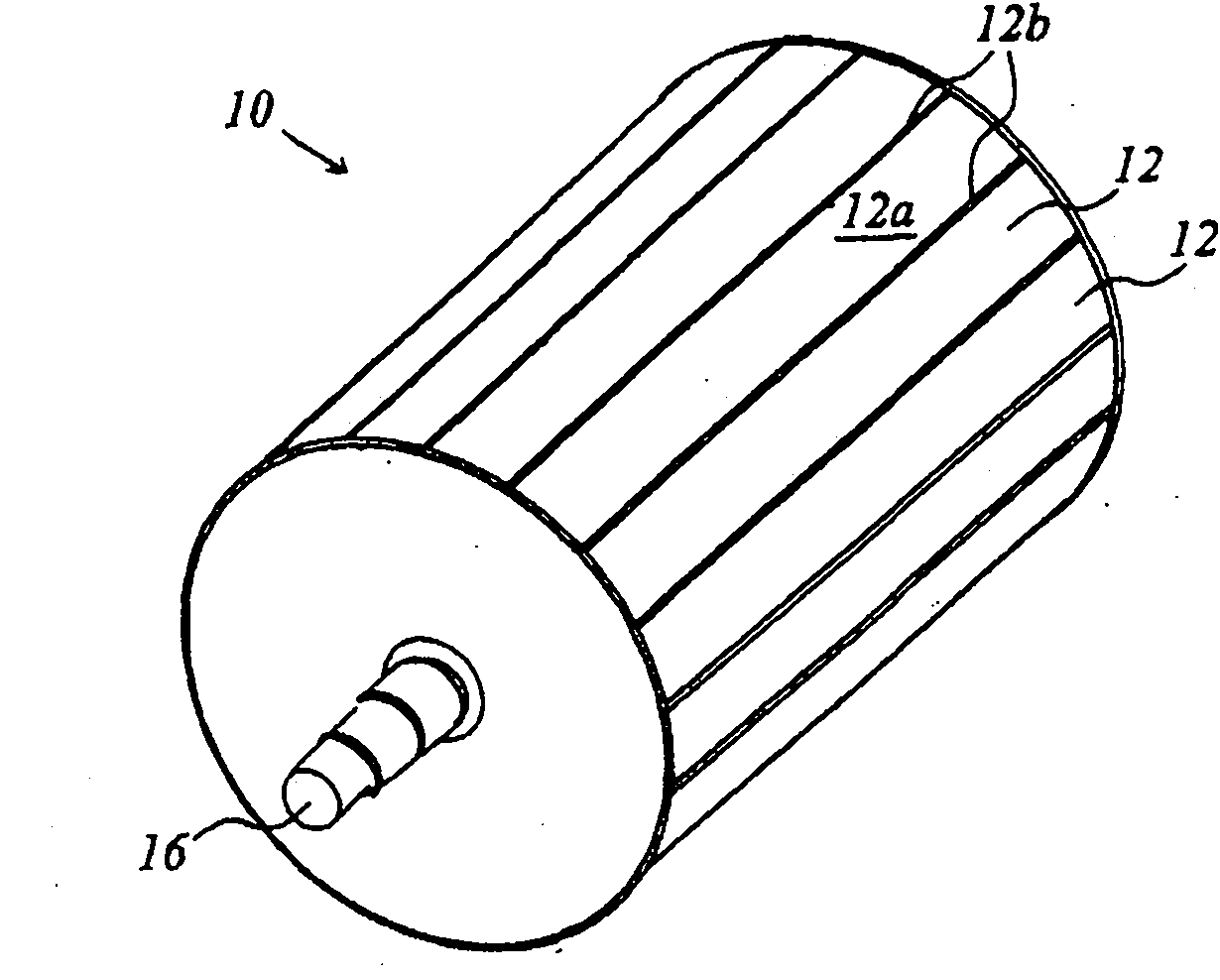

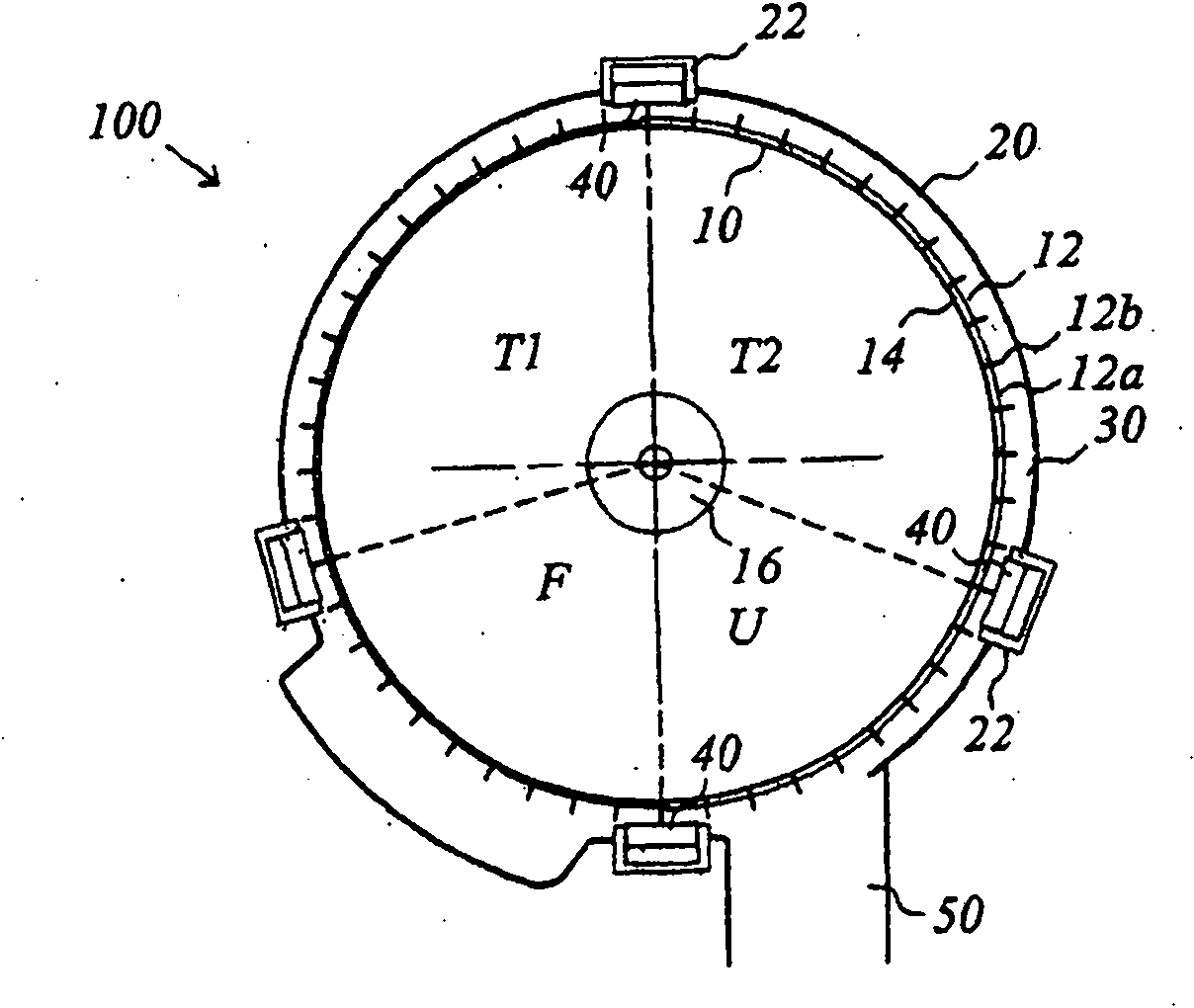

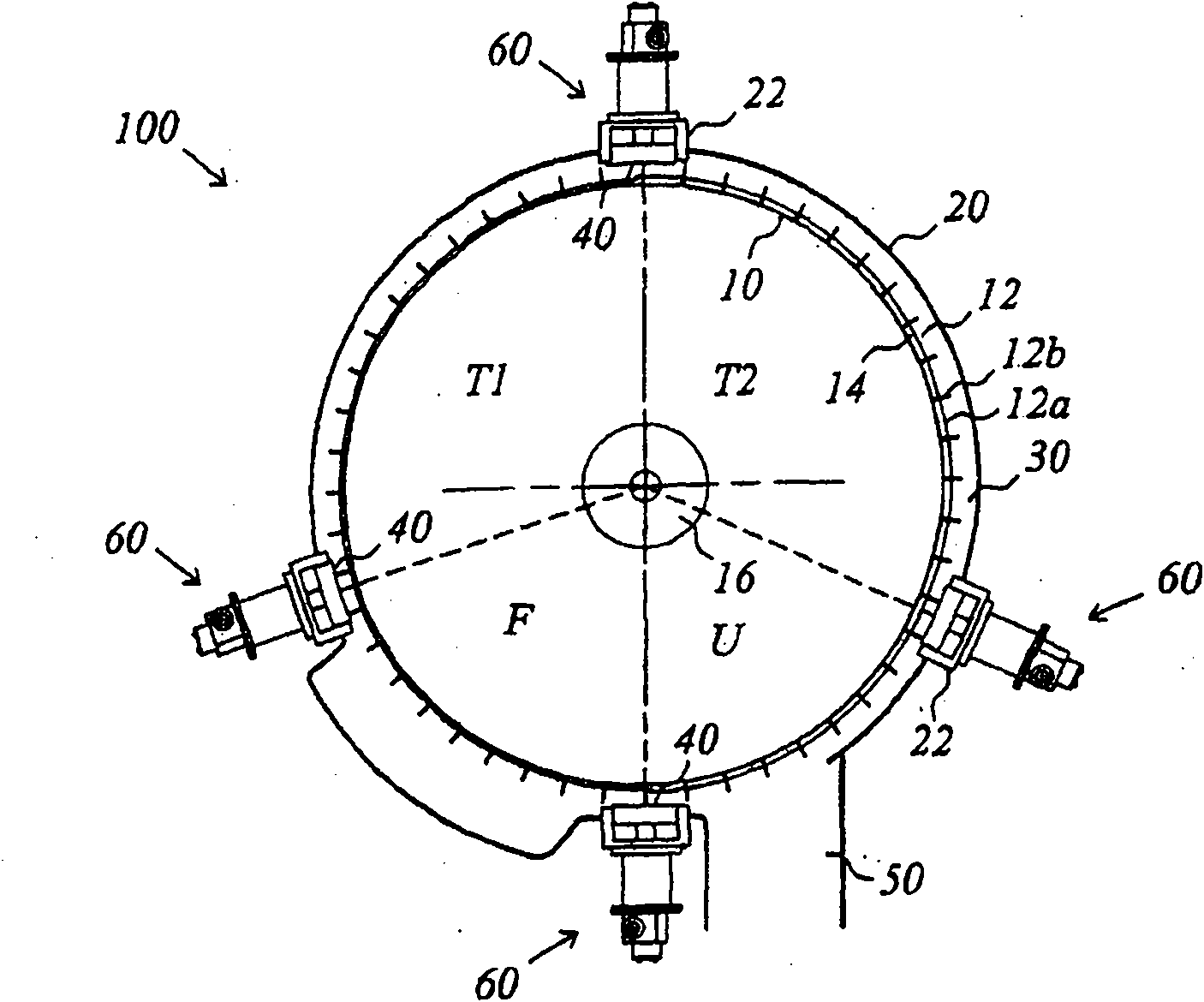

[0027] figure 1 is a schematic perspective view of a drum provided with compartments which, together with a stationary casing, can be included in a pressure displacement washer according to the invention. A drum 10 is shown provided with a plurality of external compartments (also called pulp compartments or compartments) 12 in which pulp to be washed is placed as it is fed towards the drum. Each compartment 12 has a bottom 12a constituted by a perforated plate and two compartment walls (compartment walls) 12b arranged axially with respect to the drum shaft 16 . exist figure 1 In the illustrated drum, the compartment walls 12b are evenly distributed along the circumference of the drum. The drum 10 is typically journalled on a stationary stand (not shown) in the washing apparatus and is surrounded by a cylindrical casing (eg figure 2 The reference numeral 20 in ) is enclosed, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com