Heat pump with heat recovery

A heat and liquid pump technology, used in cogeneration, fuel cell heat exchange, electrochemical generators, etc., can solve problems such as expensive heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

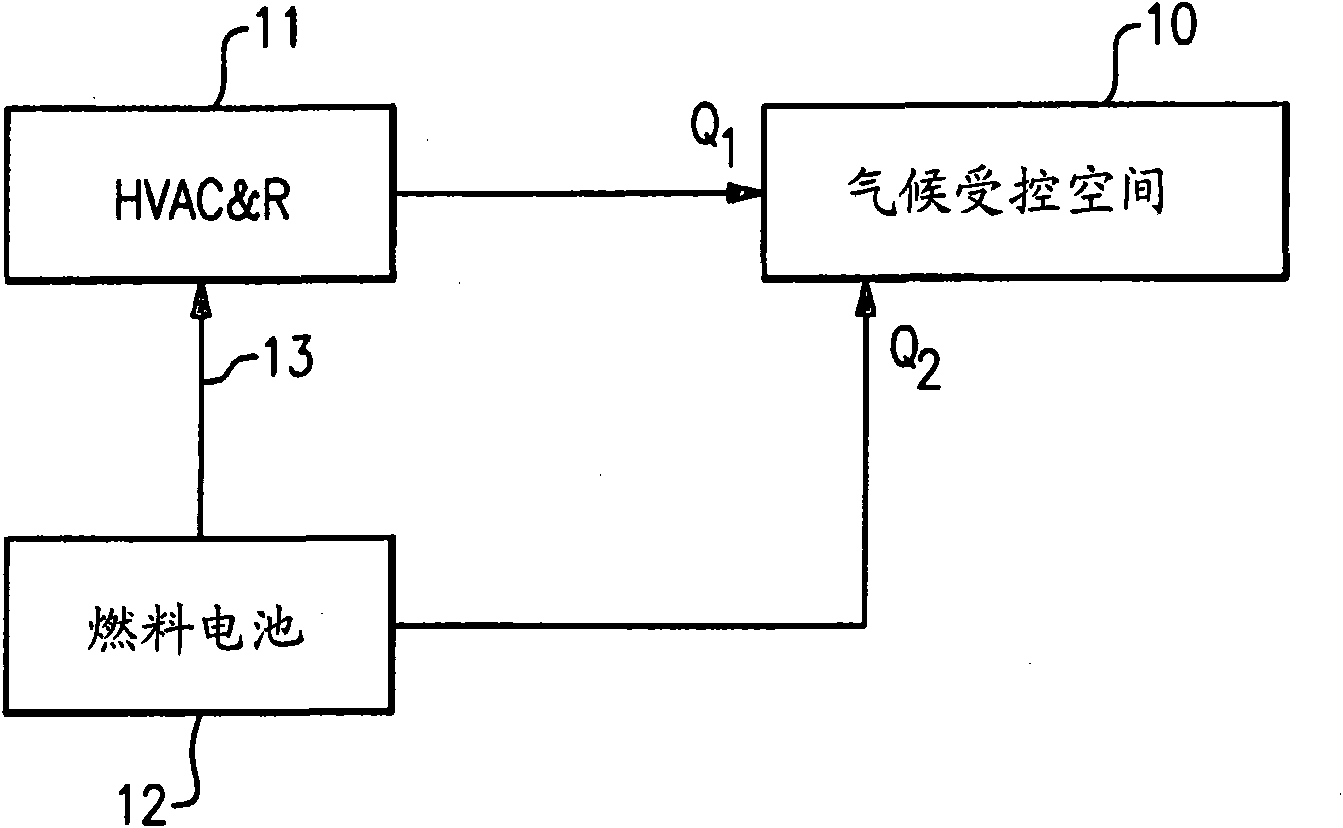

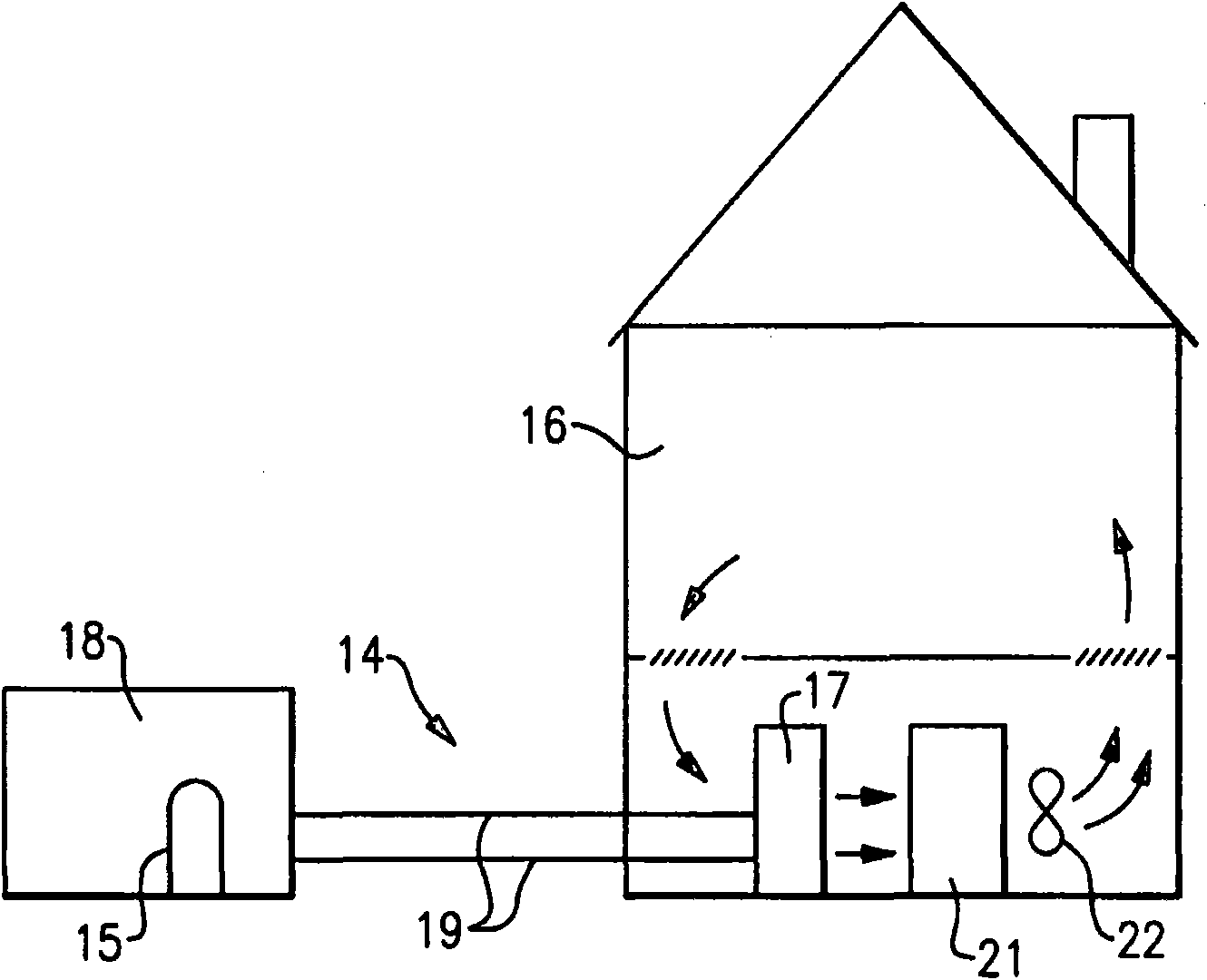

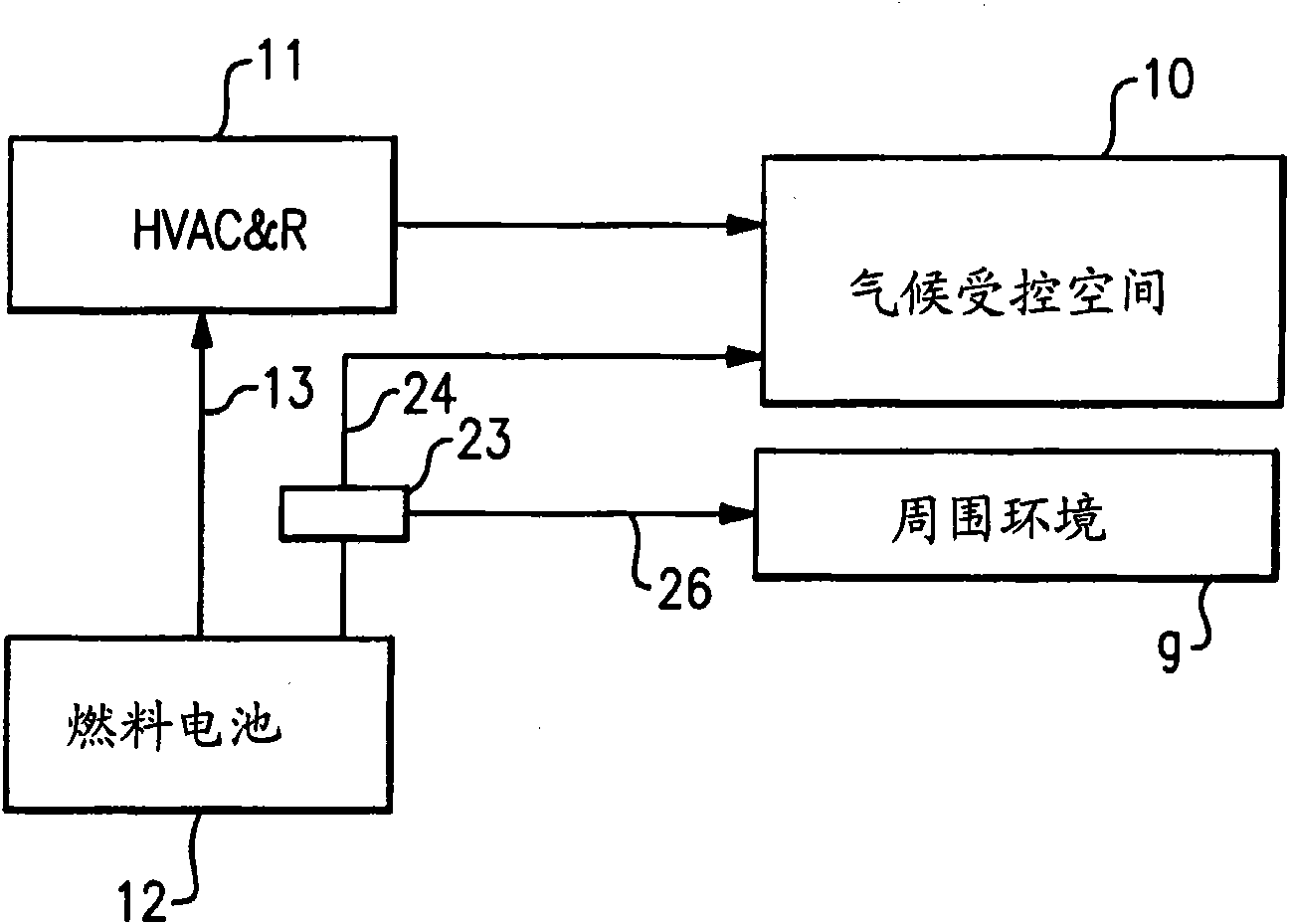

[0013] exist figure 1 A typical HVAC system 11 is schematically shown in , which may be installed to provide a comfortable environment in buildings such as commercial establishments, residences, hospitals, schools and the like. Such systems may include, but are not limited to, air conditioning and / or heat pumps, chilled water or salt water systems, and furnaces and / or hydronic heating systems, for example. A hot water heater is also available. Typically, the air conditioning system will operate in the summer, the furnace will operate in the winter, and the heat pump will operate in both seasons. The length of the cooling and heating seasons will depend on geographic location and specific applications.

[0014] A fuel cell 12 is provided for the purpose of delivering electrical energy via electrical lines 13 to the HVAC system. This arrangement allows the fuel cell 12 to provide all required electrical power to the HVAC system, and in this case, the primary power source. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com