Semi-automatic bottom sowing device

A semi-automatic, driving shaft technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as loose ropes, high labor intensity of workers, and long working hours, so as to improve the uniformity of spreading and improve the safety of operations , The effect of reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

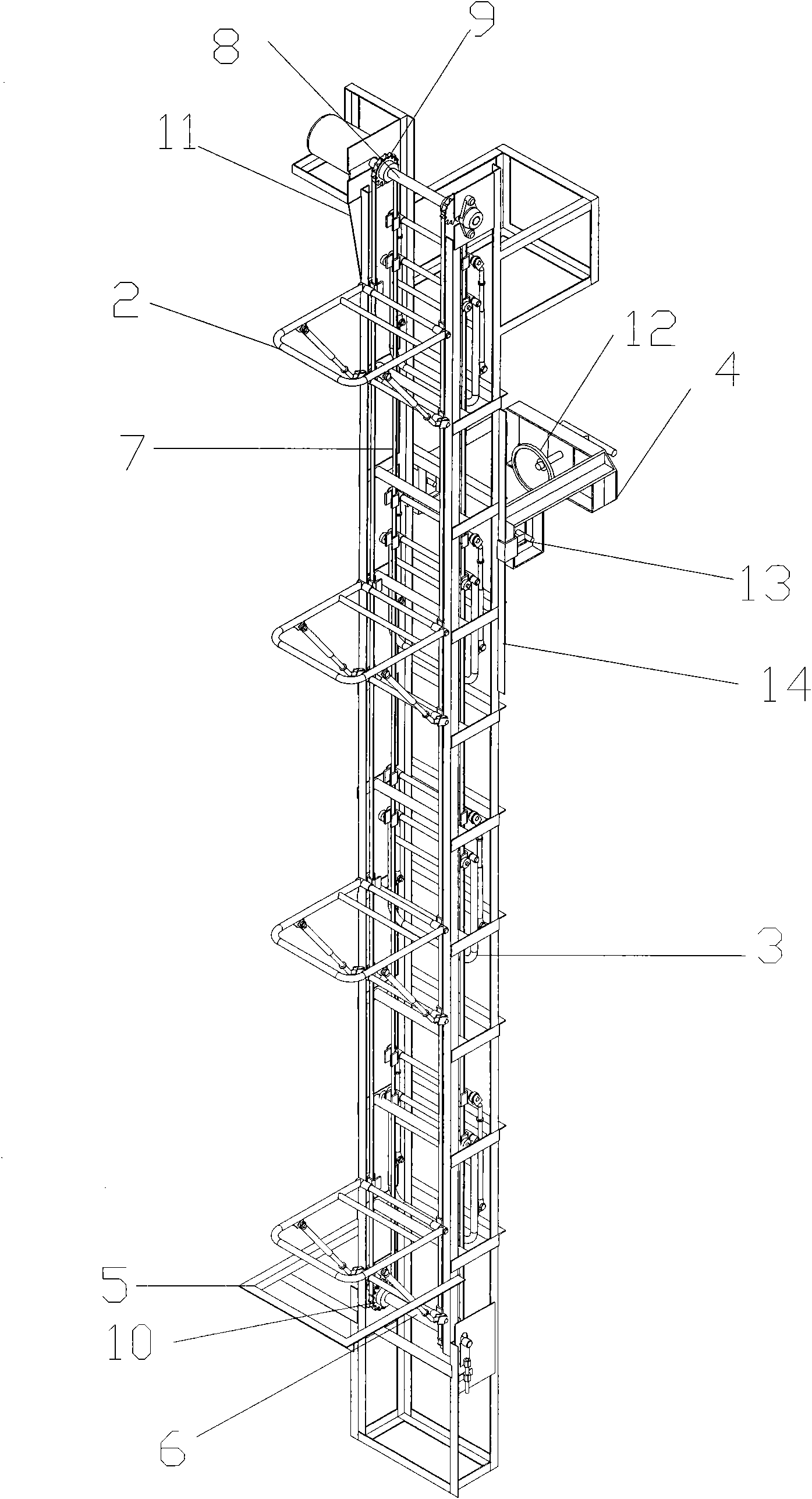

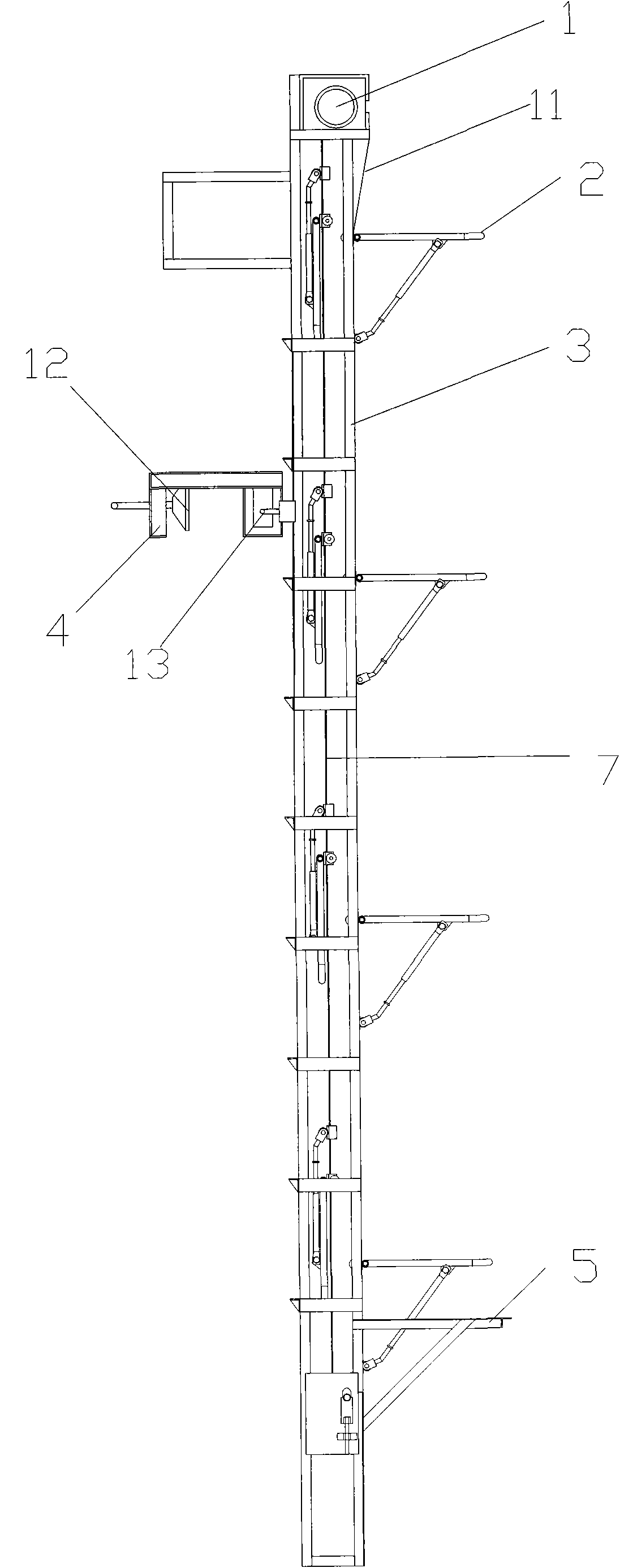

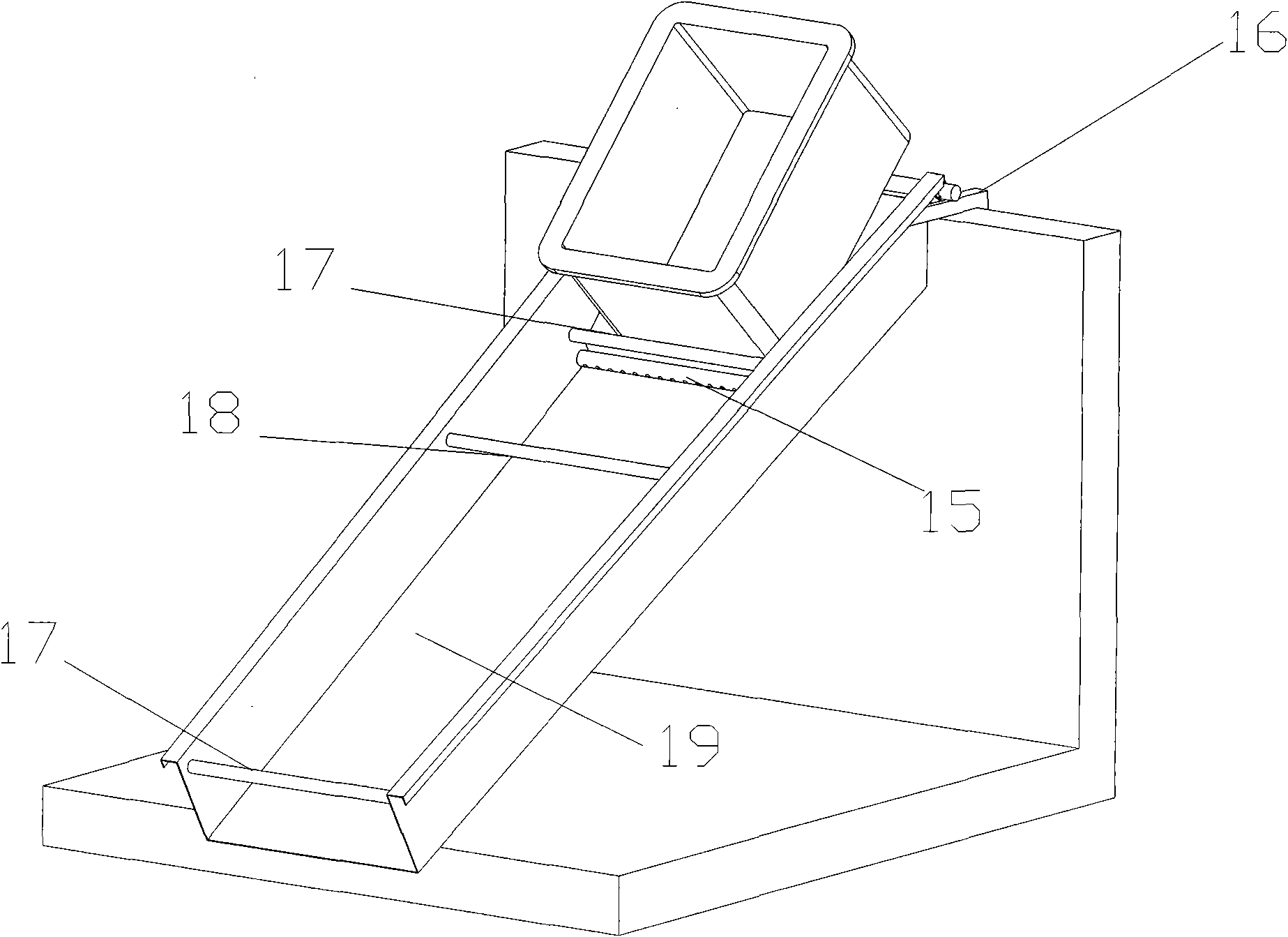

[0017] The semi-automatic bottom sowing device of the present invention is used for the bottom sowing operation, transports the seedlings in the cabin, and spreads them in the bottom sowing water area. The present invention will be further described below in conjunction with accompanying drawing.

[0018] The semi-automatic bottom sowing device includes two parts: the unloading machine A and the chute B, such as figure 1 and figure 2 As shown, the cabin machine A includes a motor 1, a bracket 2, a motor, a support 3, a fixed frame 4, a loading platform 5, a driven shaft 6, a chain 7, a driving shaft 8, a driving gear 9, a driven gear 10 and Guide plate 11; Wherein, fixed frame 4 has big handle 12 and small handle 13. Motor 1 links to each other with driving shaft 8, and guide plate 11 is arranged in the middle, and guide plate 11 prevents that when the seedling box that takes off from bracket 2 rises, just produces friction with motor 1, protects motor, and motor 1 and driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com