A vehicle-mounted road solid binder spreader

An adhesive, vehicle-mounted technology, applied in the field of vehicle-mounted road solid adhesive spreaders, can solve the problems of inability to effectively suppress dust, inaccurate measurement, inaccurate control, etc., to achieve easy operation and maintenance, and improved environmental performance. , The effect of good spreading uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

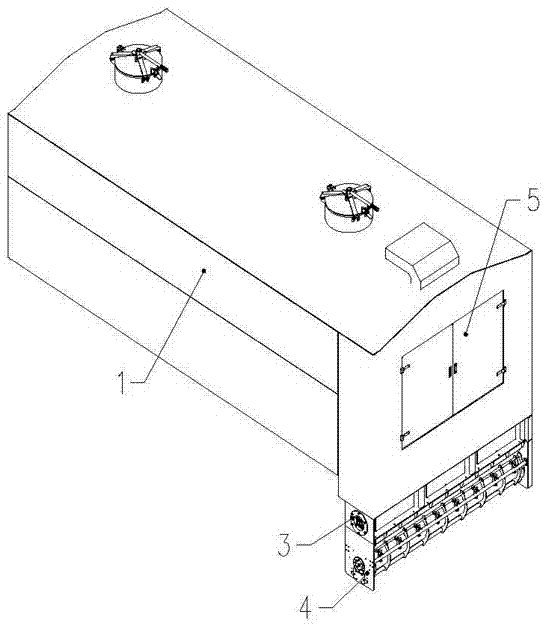

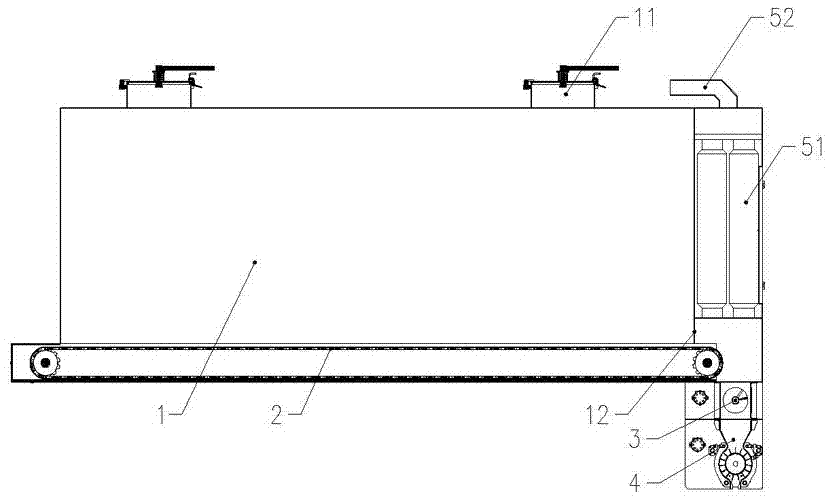

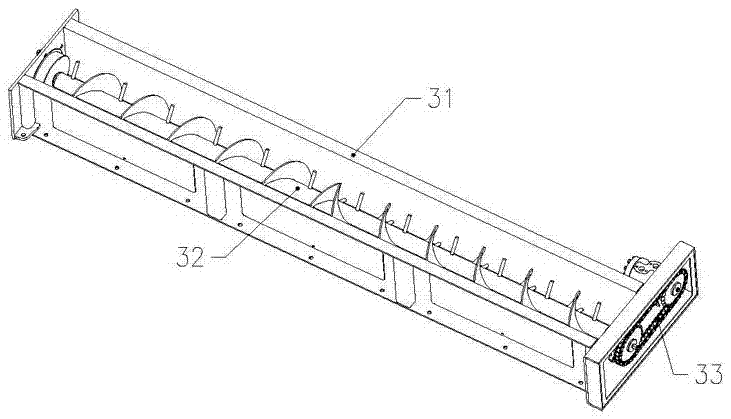

[0027] see Figure 1-Figure 2 , In order to solve the above technical problems, the present invention provides a vehicle-mounted road solid binder spreader, which includes a storage bin 1, a feeding mechanism 2, a material distribution mechanism 3, a spreading mechanism 4, and a dust removal device 5. The storage bin 1 is a square airtight box structure, the top is provided with a feed opening 11 which can be opened and closed, and the feeding mechanism 2 is sealed and connected to the lower part of the storage bin 1 and connected The discharge port 12 at the lower part of the end corresponds to; the rear end of the storage bin 1 is also sealed with a dust removal device 5; The output end of the feeding mechanism 2; the spreading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com