Processing method of changing food waste into resources

A technology of kitchen waste and treatment method, applied in the fields of environmental protection and comprehensive utilization of waste, can solve the problem of high energy consumption, achieve the effect of high production capacity and reduce investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

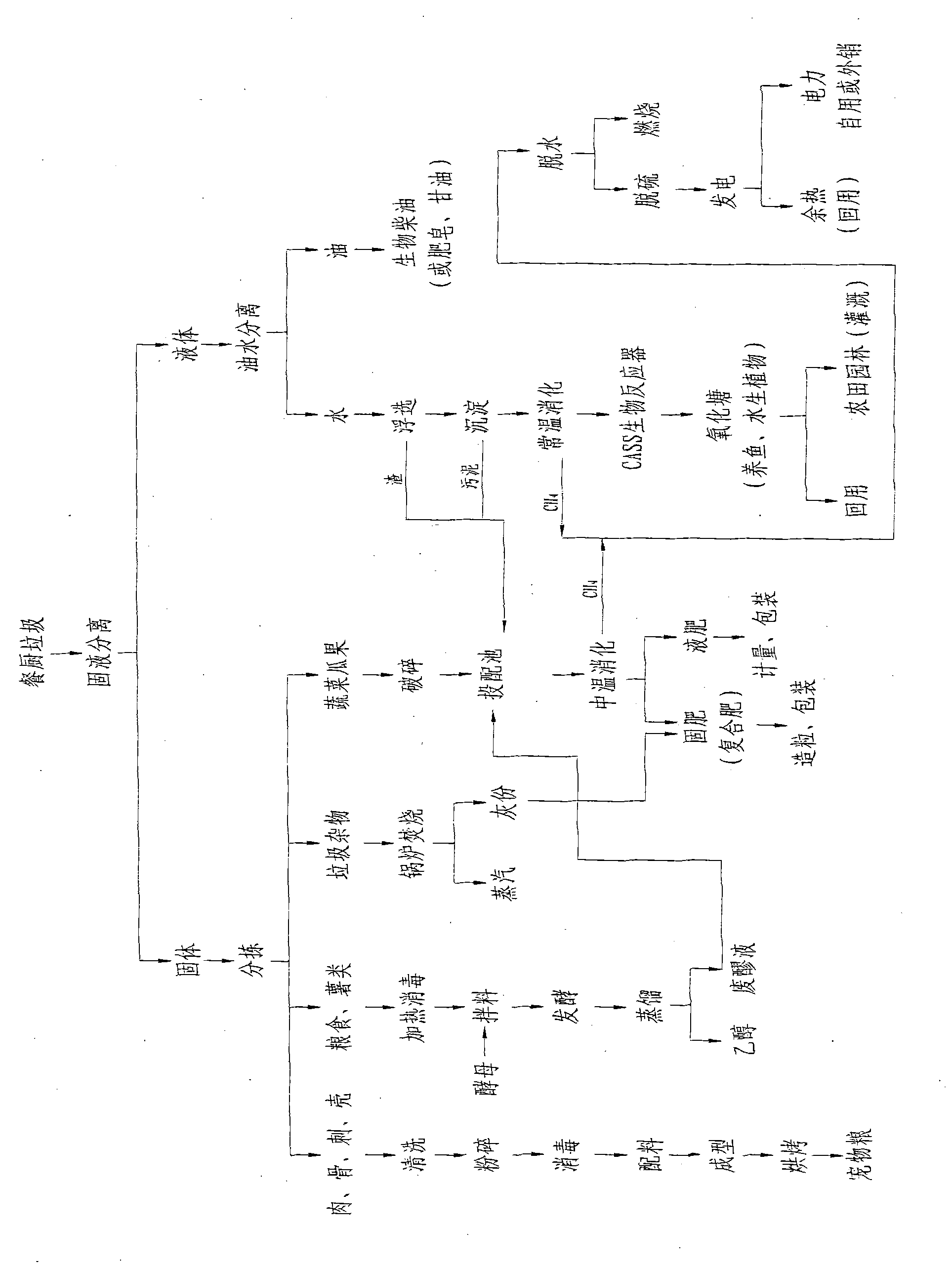

Image

Examples

Embodiment Construction

[0028] Design and build high-level swill tanks, grease traps, flotation tanks, sedimentation tanks, suction tanks, sealed anaerobic digestion tanks, CASS tanks, oxidation ponds, sorting rooms, ethanol fermentation, distillation rooms, etc. according to the predetermined processing capacity and process requirements. Biodiesel room, pet food room, generator room, power distribution room, boiler room, laboratory, warehouse, etc., and supporting pipe network, power, and control lines.

[0029] Such as figure 1 As shown, the food waste resource treatment process is as follows:

[0030] 1. Separating the kitchen waste into solid and liquid, and separating the separated solids into grains, potatoes, vegetables and fruits, animal bones and fish bones, and garbage (bamboo, wood, paper, plastic, etc.), according to the following Treat separately:

[0031] 1) After heating and sterilizing grain and potatoes, add yeast mixture according to the existing ethanol production method, ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com