Special joint feature detection and parameter regulation device for robot

A parameter adjustment device and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of mechanical body impact and damage, and achieve the effect of avoiding impact and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

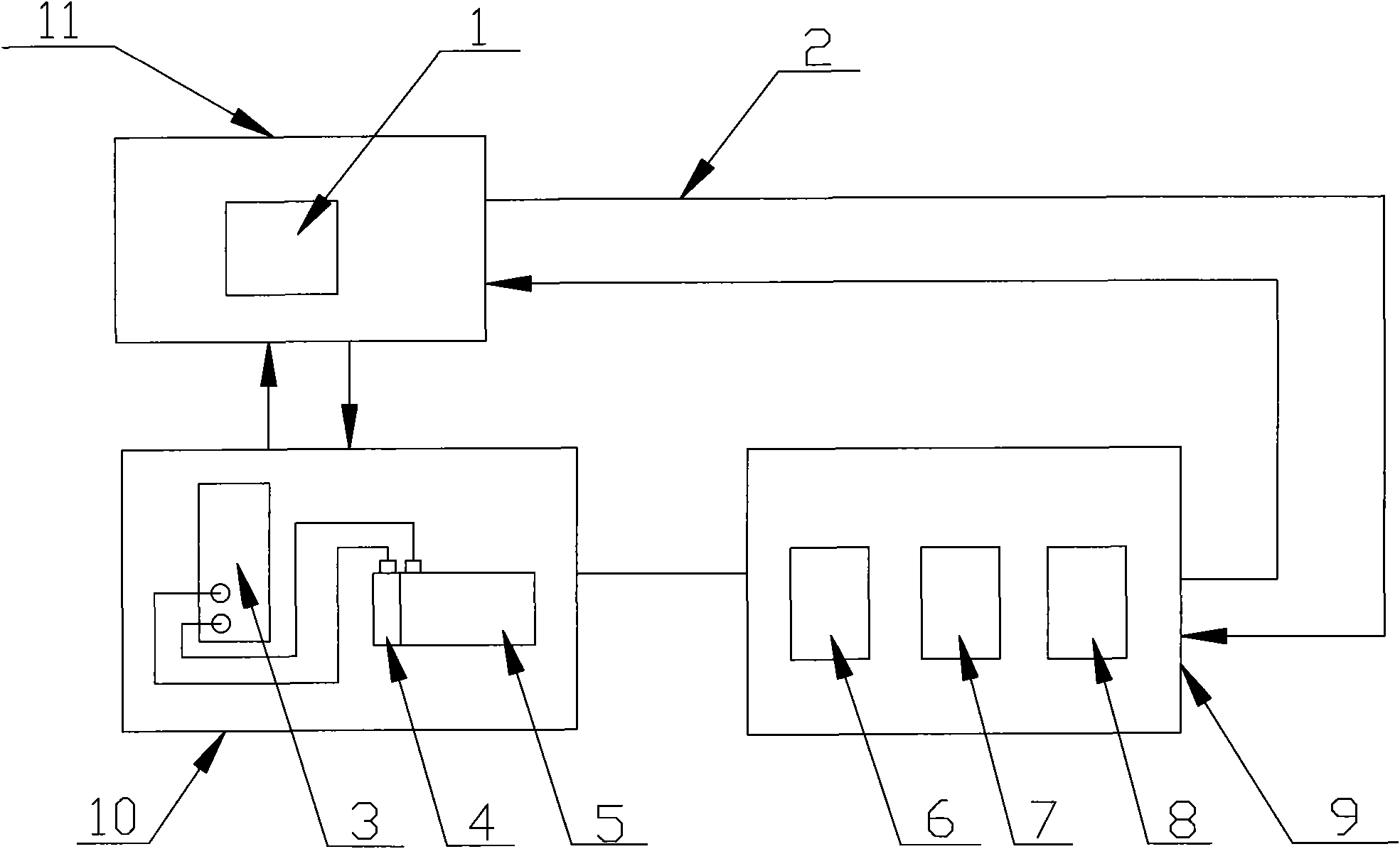

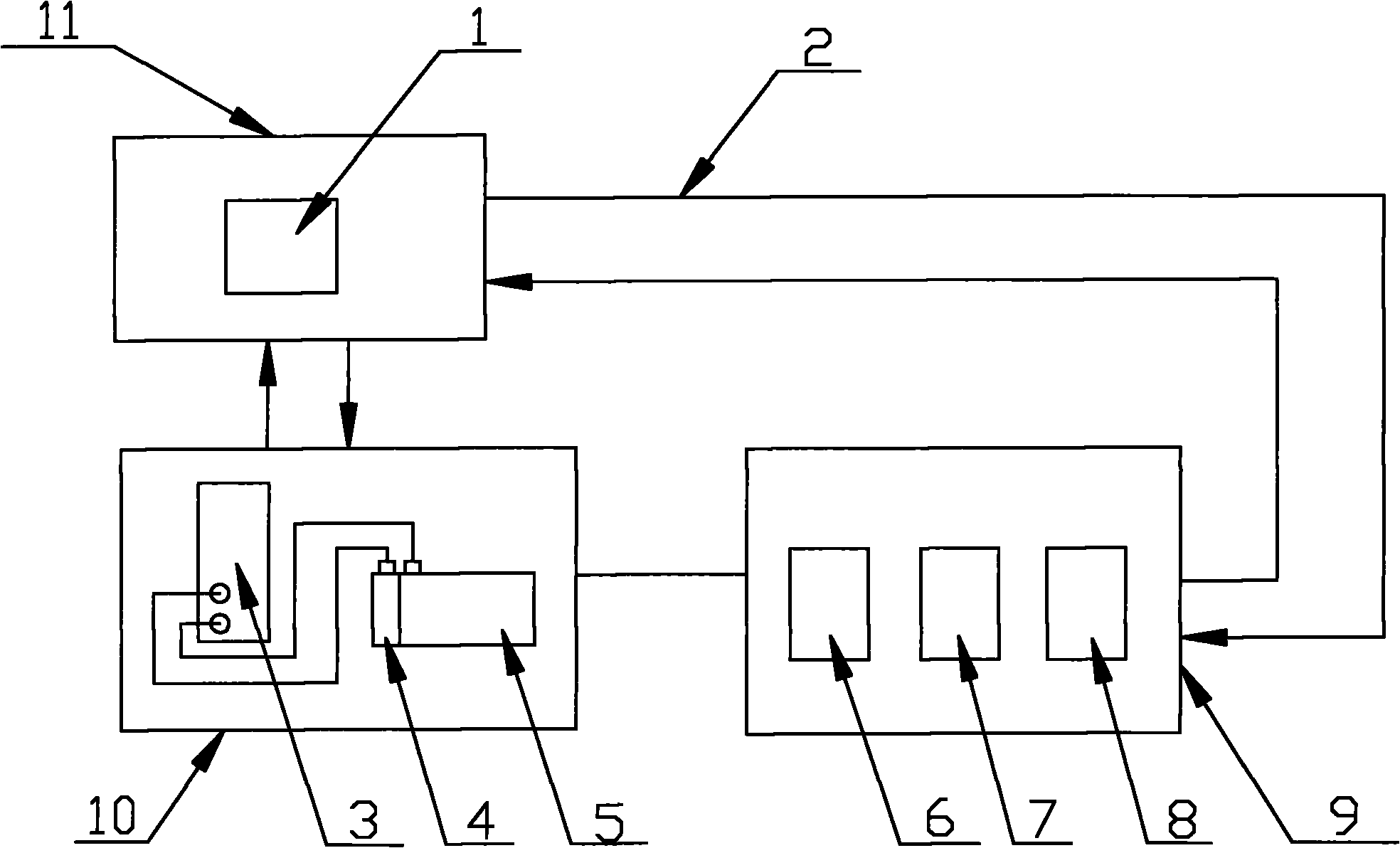

[0022] Such as figure 1 A special joint characteristic detection and parameter adjustment device for a robot is shown, which has a control and processing unit 11, a servo drive unit 10, a reducer and a load unit 9, and the control and processing unit 11 is connected with the servo drive unit 10, the reducer and the load The unit 9 transmits instructions and data through the high-speed communication bus 2 , and the servo drive unit 10 drives the reducer and the load unit 9 . The servo drive unit 10 includes a high dynamic performance servo motor driver 3 with a current real-time feedback interface, a 17-bit high-precision encoder 4 at the motor end and a high dynamic performance servo motor 5, and the servo motor driver 3 controls 17 bits through a line connection. High-precision encoder 4 and servo motor 5. The reducer and load unit 9 includes a reducer 6 for testing, a variable inertia load 7 and a 24-bit high-precision encoder 8 at the load end of the reducer.

[0023] Tes...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap