Robot joint redundancy control system and control method thereof

A technology of robot joints and redundant control, applied in the field of servo control systems, can solve the problem of inability to reconfigure the resources of the primary system and backup system, and achieve the effect of ensuring normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

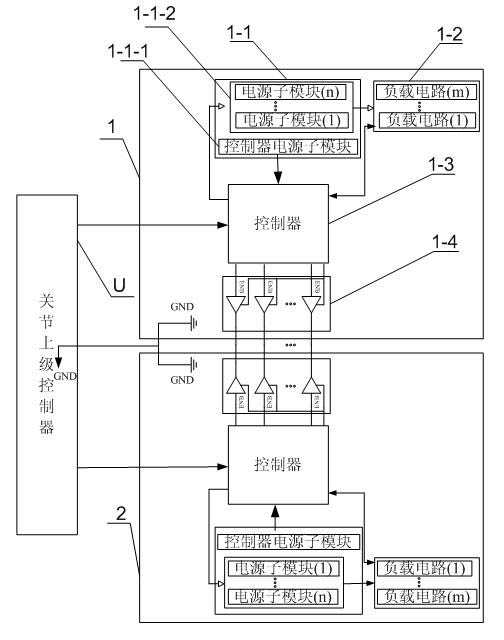

[0018] Specific implementation mode one: according to the instructions attached figure 1 , 2 and 3 specifically illustrate this embodiment, a robot joint redundant control system described in this embodiment, which includes a master control unit 1 and a backup control unit 2, and the master control unit 1 and the backup control unit 2 have the same structure , the ground wire of the primary control unit 1 and the ground wire of the backup control unit 2 are both connected to the control system return line, and the primary control unit 1 and the backup control unit 2 are connected through a signal line,

[0019] The primary control unit 1 includes a power supply module 1-1, a load circuit group 1-2, a controller 1-3 and an information exchange control module 1-4,

[0020] The power module 1-1 is used to provide power to the controller 1-3, and is also used to turn on or turn off the power output to the load circuit group 1-2 after receiving the power control signal from the co...

specific Embodiment approach 2

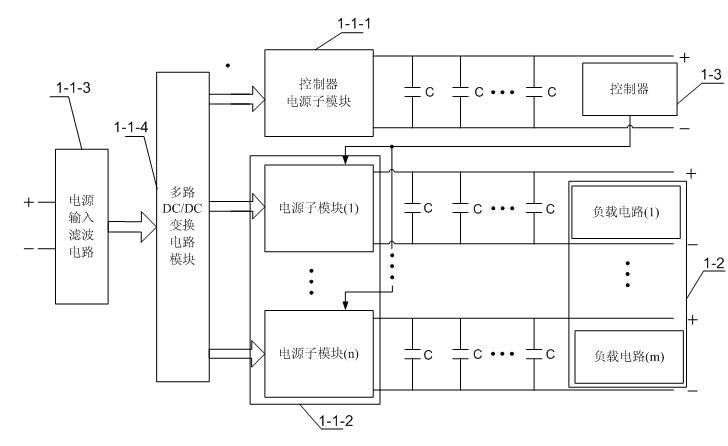

[0024] Embodiment 2: This embodiment is a further description of Embodiment 1. The power supply module 1-1 in Embodiment 1 includes a controller power supply submodule 1-1-1 and a load circuit power supply submodule group 1- 1-2,

[0025] The controller power supply sub-module 1-1-1 is used to provide power to the controller 1-3,

[0026] The load circuit power supply submodule group 1-1-2 includes n power supply submodules, n>1, and is a natural number, and the load circuit group 1-2 includes m load circuits, m>1, and is a natural number, The load circuit power supply submodule group 1-1-2 is used to turn on or turn off the power output to the load circuit group 1-2 after receiving the power control signal from the controller 1-3, so as to realize the control of the load circuit Individual control of each load circuit in groups 1-2.

specific Embodiment approach 3

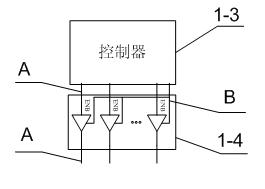

[0027] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The information exchange control modules 1-4 described in Embodiment 1 or 2 are multiple tri-state bidirectional data buffers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com