Narrowing method of straddle-type monorail transit curved track beam

A straddle-type monorail and curved track technology, applied in tracks, roads, buildings, etc., can solve the problems of high power consumption, short service life, large deformation, etc., to increase service life, prevent tire blowouts, and reduce compression deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

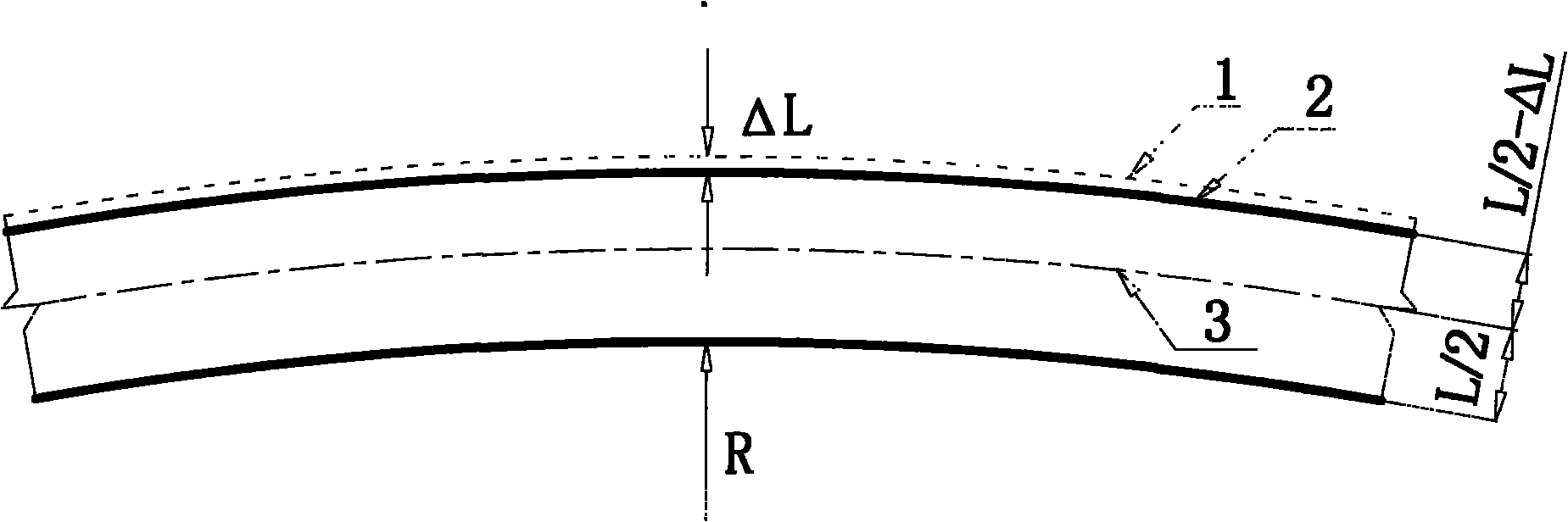

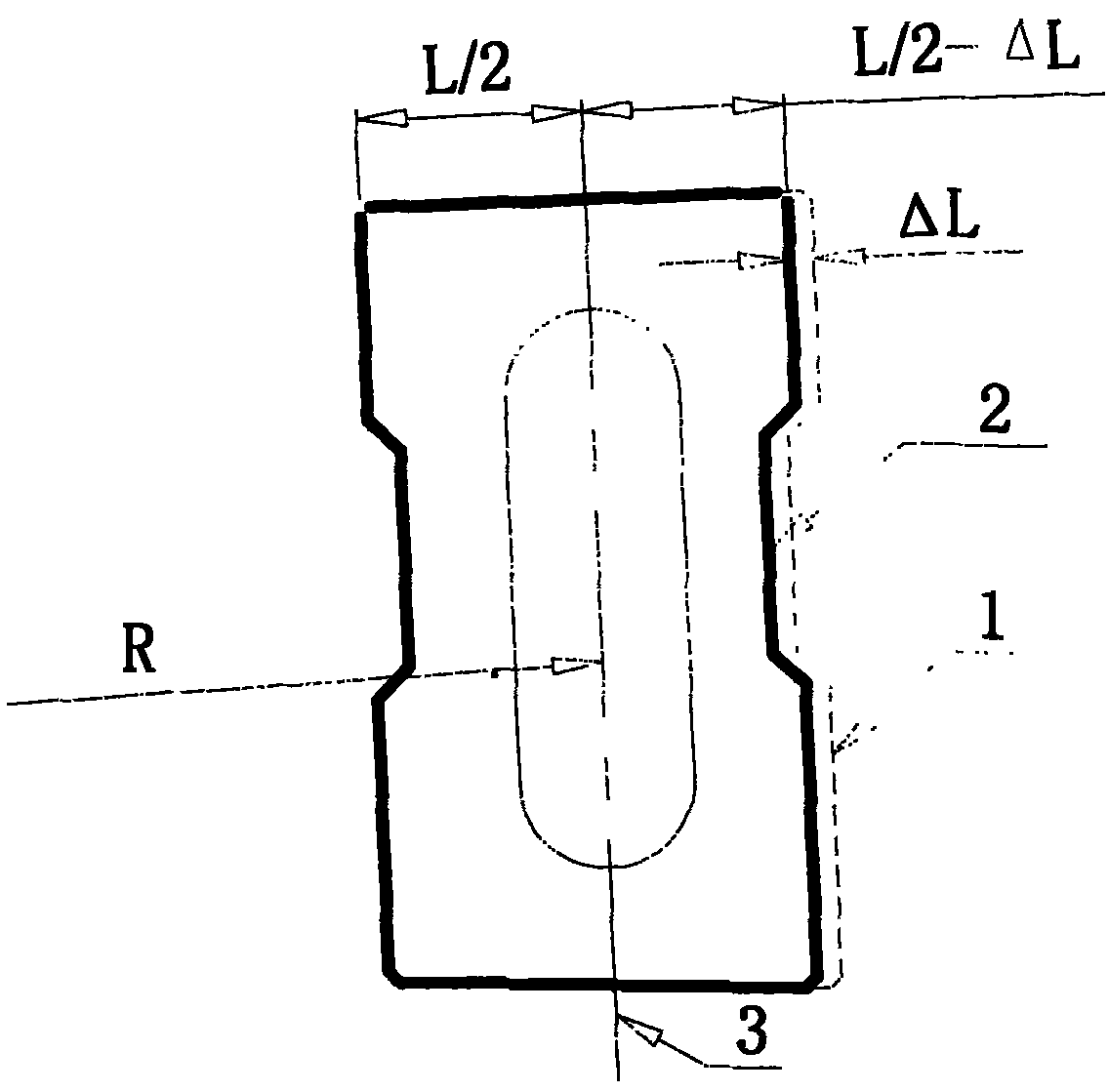

[0046] Example 1 The width of the curved track beam is narrowed, see figure 1 .

[0047] Take the narrowing of the width of the curved track beam on the line with the radius of the circular curve R=100m as an example for illustration.

[0048] Using large vehicles, the standard width of the track beam is 850mm. Since R≤150m, the beam width reduction value ΔL is 15mm from table 2, and the narrowed width of the curved track beam is 835mm.

[0049] When the track beam is manufactured, the position of the outer formwork of the curved track beam is moved from the original design position 1 to the center of the curve by 15mm to the narrowed formwork position 2, and the position of the inner formwork remains unchanged. When the track beam is erected, the center line of the line remains unchanged, and the track beam is measured, positioned and erected according to half the standard beam width from the inner side of the curved track beam to the line center line.

example 2

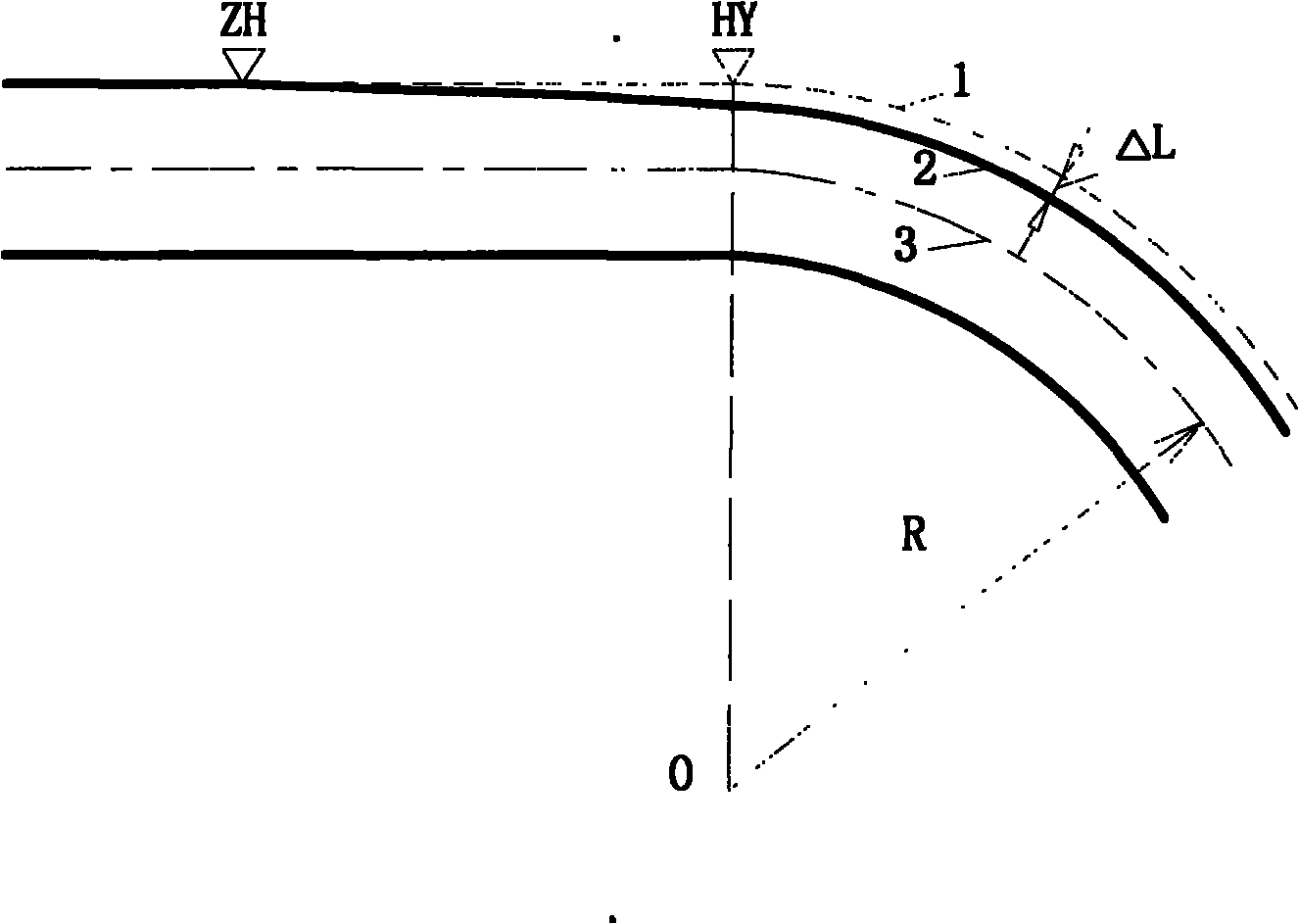

[0050] Example 2 Straight line + transitional curve + circular curve track beam width narrowed, see image 3 .

[0051] Take the narrowing of track beam width on the line of straight line + transitional curve (length 72m) + circular curve (radius R = 100m) as an example for illustration.

[0052] Using a large vehicle, when the plane circular curve radius R=100m, since R≤150m, the beam width reduction value ΔL obtained from Table 2 is 15mm, and the narrowed width of the circular curve segment track beam is 835mm. This line is provided with a transitional curve, so the change in the width of the curved track beam should decrease uniformly within the entire transitional curve between the straight line and the circular curve, and the rate of decrease is ΔL / S=15 / 72000=0.2‰, which is far less than the allowable rate of decrease Value 2‰.

[0053] When the track beam on the transition curve is processed and manufactured, the position of the outer formwork of the curved track beam ...

example 3

[0054] Example 3 The width of the track beam on the straight line + circular curve is narrowed, see Figure 4 .

[0055] The narrowing of the width of the track beam on the line of straight line + circular curve (radius R=100m) is taken as an example for illustration. Using a large vehicle, when the radius of the circular curve is R=100m, the beam width reduction value ΔL obtained from Table 2 is 15mm, and the narrowed width of the track beam at the circular curve section is 835mm. Since there is no transition curve, the track beam width should be reduced within a certain length on the straight beam section. Since the decline rate should not be greater than 2‰, the required decreasing length on the straight beam section should be at least S=15mm / 0.002= 7500mm = 7.5m.

[0056] When the track beam is manufactured, the position of the outer formwork of the track beam is moved from the original design position 1 to the narrowed position 2 in the direction of the center of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com