Vent-gas torch waste-heat power generation comprehensive utilization device

A technology of releasing air and thermal power generation, which is applied in steam engine devices, ignition by electric spark, combustion ignition, etc. It can solve the problems of waste heat recycling, energy waste, environmental pollution, etc., to reduce pollution, improve heat exchange efficiency, The effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

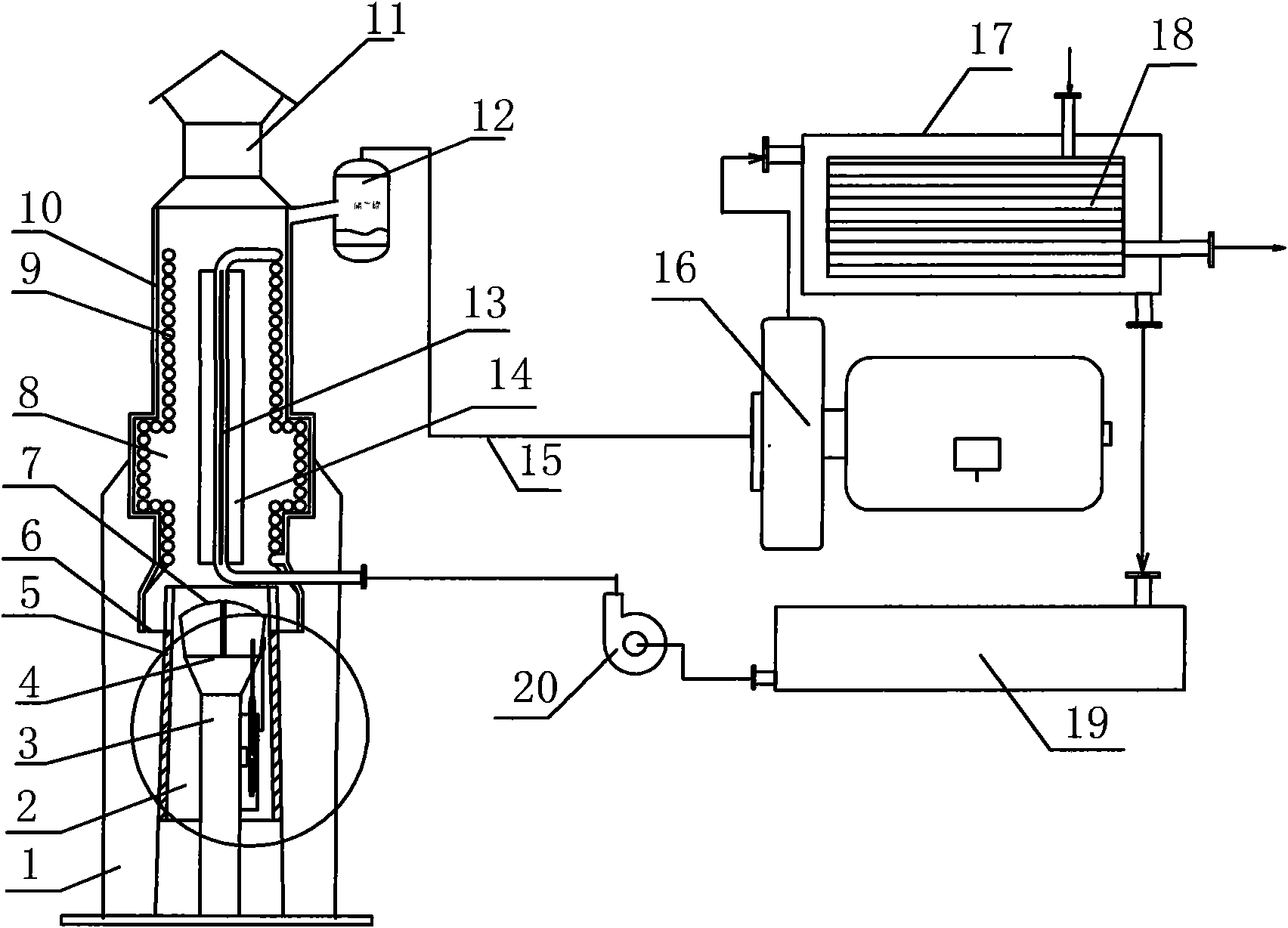

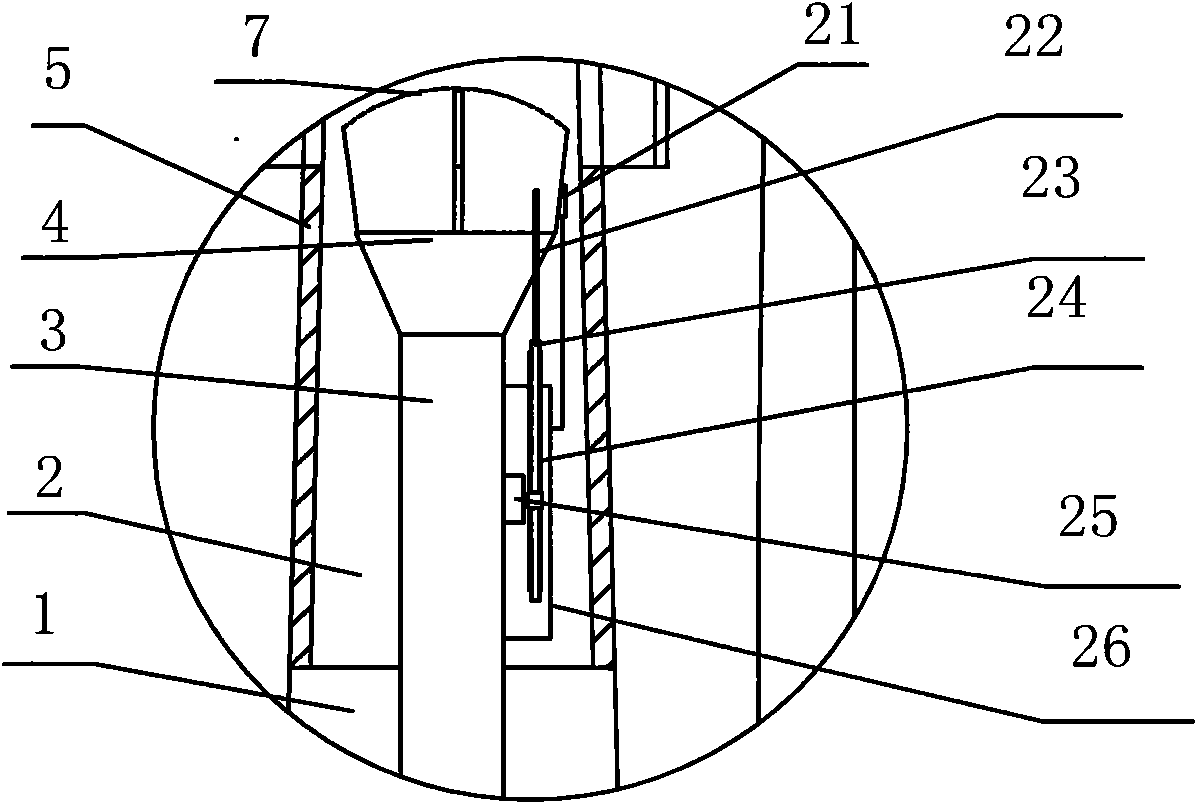

[0017] The device of the present invention will be described in detail below with reference to the accompanying drawings.

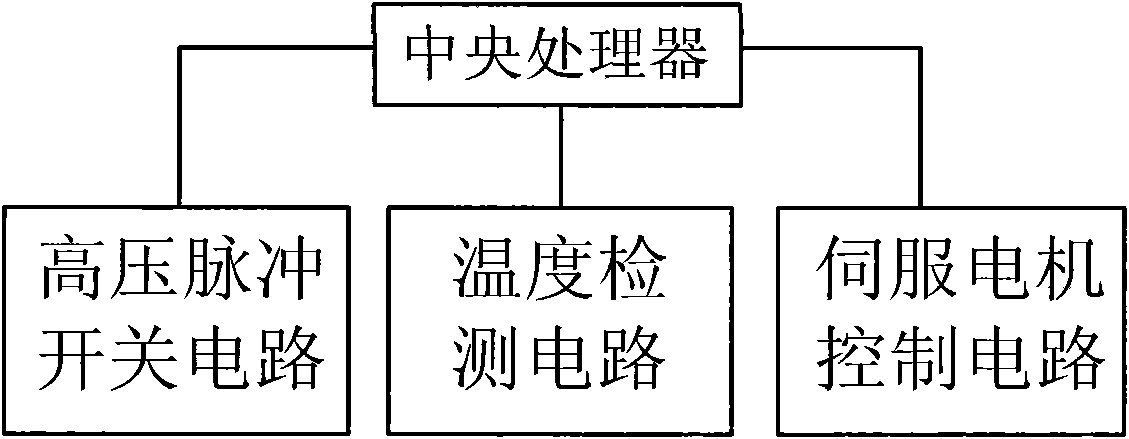

[0018] The comprehensive utilization device for waste heat power generation of the air-venting torch of the present invention is composed of a combustion device and a waste heat comprehensive utilization device, wherein the combustion device is composed of a waste gas evacuation pipe 3, a gas burner 4, an air and heat pipe, 5, and a support 1 , a jacketed furnace body 10, a serpentine heat exchanger 9, a standpipe heat exchanger 13, a rainproof cap 11 and an automatic ignition device. The upper end of the waste gas exhaust pipe 3 is provided with a gas burner 4, and the support 1 is arranged between the air and the On the outer wall of the heat pipe 5, the waste gas exhaust pipe 3 and the gas burner 4 are located in the middle of the air preheating pipe 5, the upper part of the bracket 1 is connected with the outer wall of the jacketed furnace body 10, and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap