Telescopic connected high-efficiency dual-purpose water tank

A sleeve-type, joint-mounted technology, applied in heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problems of low heat exchange efficiency, easy to be affected by the environment, and short service life of heat exchange tanks, and achieve heat exchange The effect of high utilization rate, long service life and small output resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

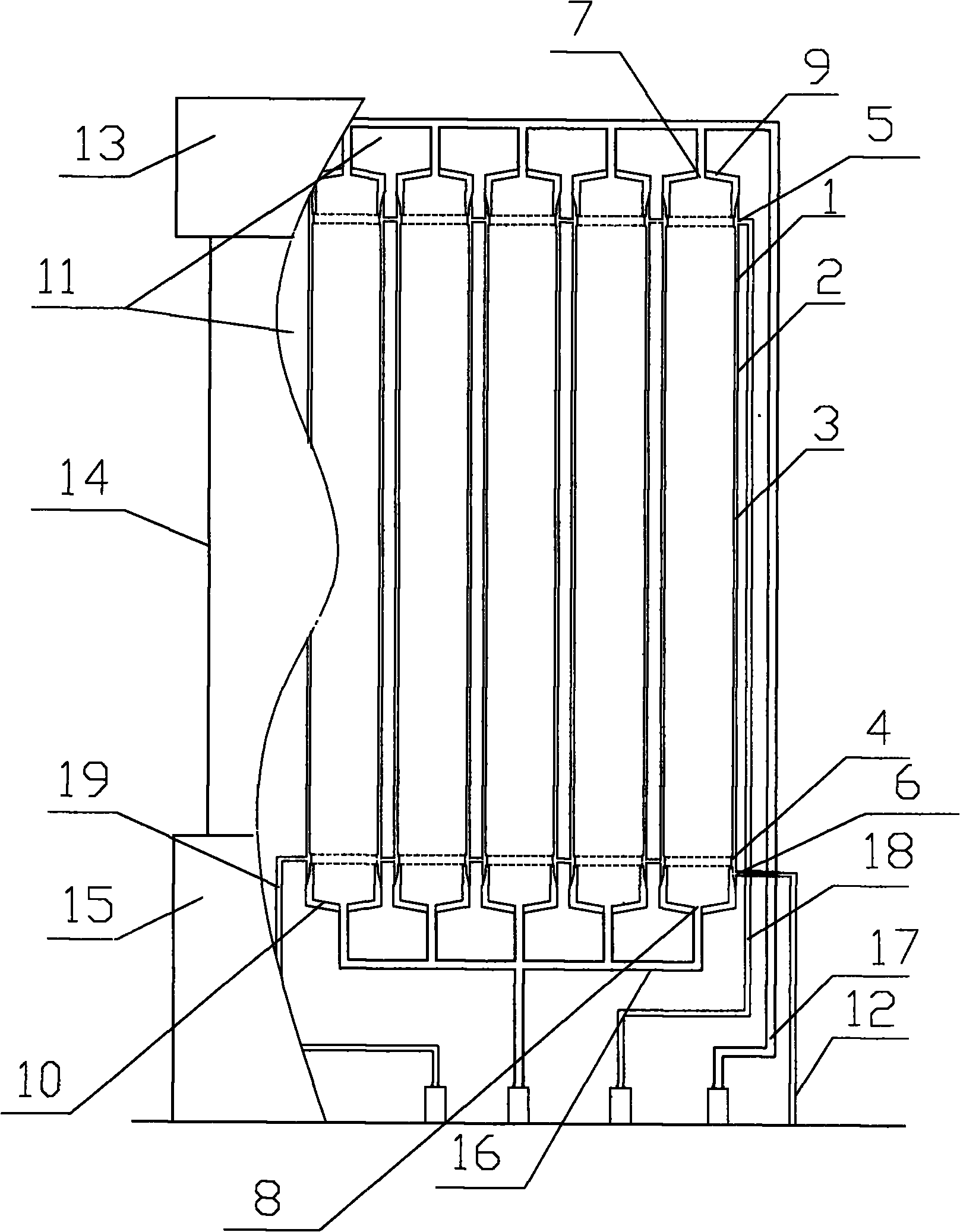

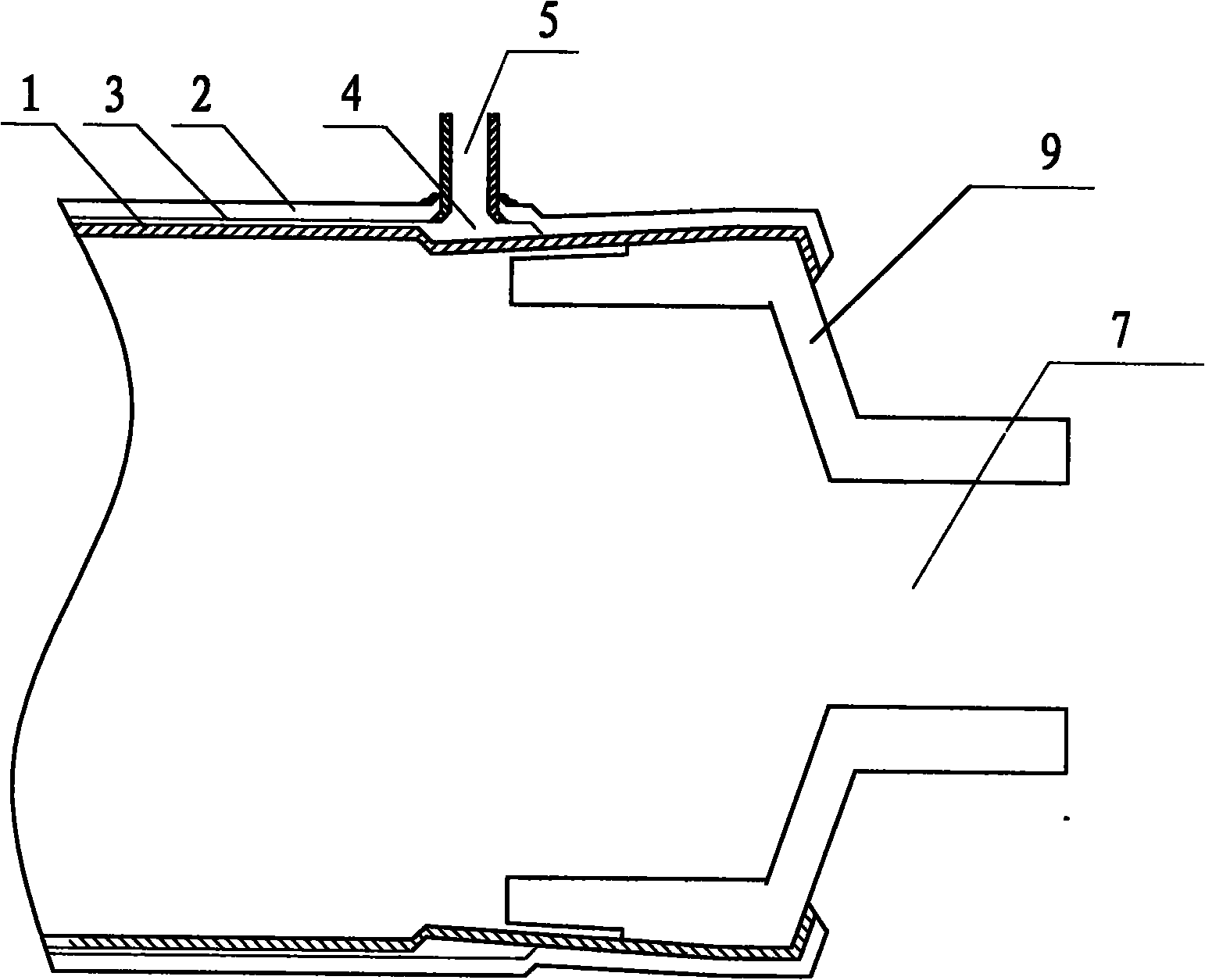

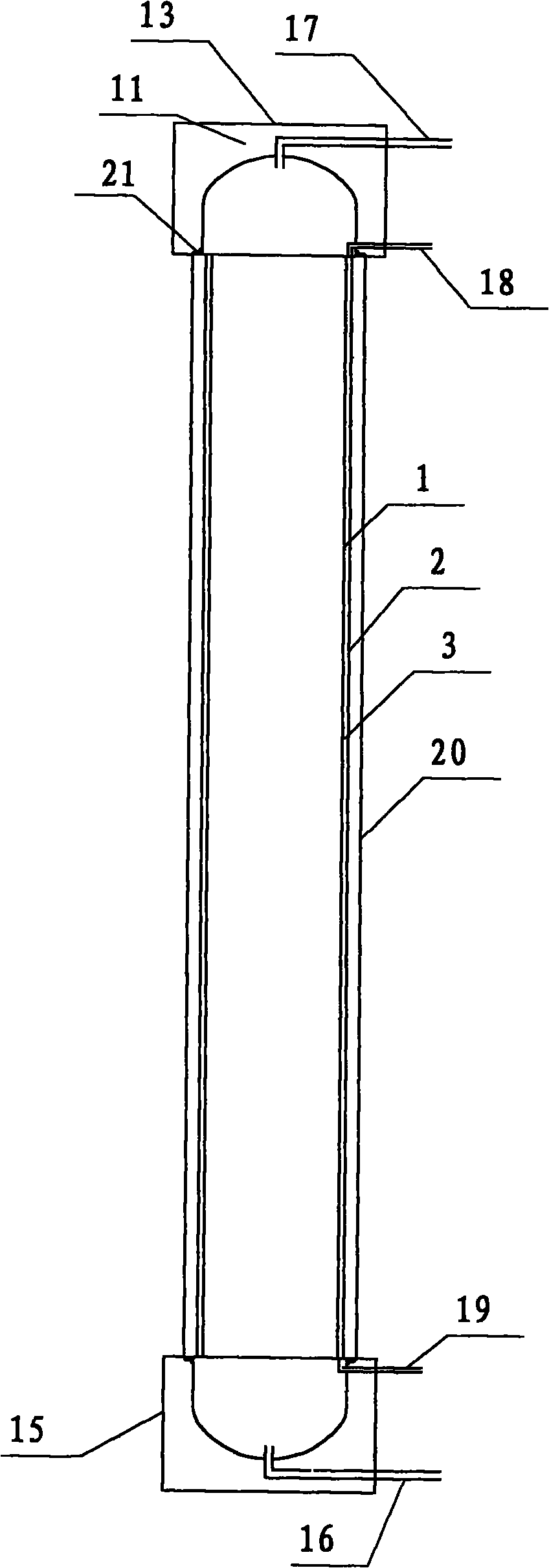

[0024] The sleeve-type joint-mounted high-efficiency dual-purpose water tank includes a shell and a water bladder, and the structure is as follows figure 1 As shown, the top structure of the water tank is as follows figure 2As shown, the water bladder is made of an upper end cover 9, a lower end cover 10 and a double-layer metal tube. The upper end cover 9 is provided with a hot water outlet 7, and the lower end cover is provided with a cold water inlet 8. The double-layer metal tube consists of an outer tube 2 and an inner tube. The upper end of the inner tube 1 is fixed with the upper end cover 9, the lower end of the inner tube 1 is fixed with the lower end cover 10, the outer tube 2 is set outside the inner tube 1, and the upper end of the outer tube 2 is connected with the inner tube 1. The upper ends are fixed together, the lower end of the outer tube 2 and the lower end of the inner tube 1 are fixed together, and there is a gap of 0.04-0.6 mm between the inner wall of ...

Embodiment 2

[0035] The sleeve-type joint-mounted high-efficiency dual-purpose water tank is the same as that of Embodiment 1, the difference is that: there are 10 water bladders in the sleeve-type joint-mounted high-efficiency dual-purpose water tank, the middle part of the shell is an outer cover with a glass plate on one side, and the other three sides It is made of opaque material, and the side of the outer tube opposite to the glass plate is provided with a black coating. A partition is used to divide the middle part of the shell into two parts. The partition and the center of each water bladder are on the same plane, between the outer tube and the opaque side The gap is filled with insulating material, and the outer surface of the outer tube opposite to the transparent side is coated with a black coating.

[0036] The heat exchange area is 0.076m×3.14m×1.8m×10=4.3m 2 , volume ratio V=(S1-S2) H N (where S1 is the inner circle area of the outer tube, S2 is the outer circle area of ...

Embodiment 3

[0040] The water tank structure of the sleeve-type joint-mounted high-efficiency dual-use water tank is the same as that of Example 1, except that the outer tube adopts a general-purpose tensile aluminum alloy tube with an inner diameter of 114.5mm and a wall thickness of 1.8mm, and the length is 1.8m. The surface is coated with black coating, and the inner tube is made of 304 stainless steel tube with an outer diameter of 114.4mm and a wall thickness of 1.6mm.

[0041] The pressure of the outer pipe is (2×1.8×160Mpa) / 114.5=5.03Mpa, the pressure of the inner pipe is (2×1.6×380 / 2Mpa) / 114.4=5.3Mpa, when the tap water pressure is 3kg, the maximum pressure at the end Only (11.4 / 2) 2 ×π×3=306kg.

[0042] There are 6 water tanks in the sleeve-type joint-mounted high-efficiency dual-use water tank, which are fixed on the footing bracket in a single row. The total heat exchange area of the water tanks is 0.114m×3.14m×1.8m×6 = 3.87m 2 , volume ratio V=(S1-S2) H N (where S1 is the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com