Rotatable component of incineration hearth of cooking and heating furnace

A technology for heating stoves and hearths, which is applied in the direction of household stoves/stoves, climate sustainability, and combustion technology mitigation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

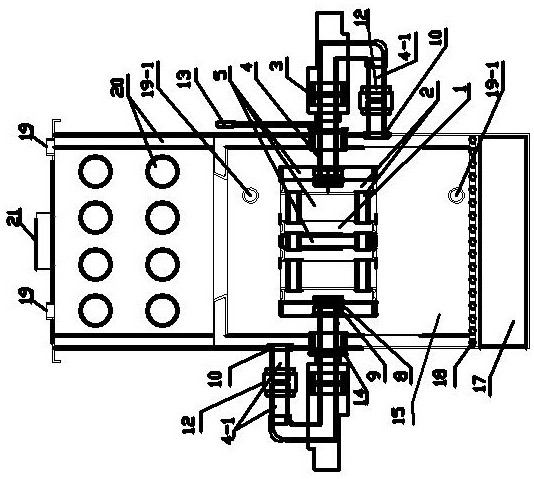

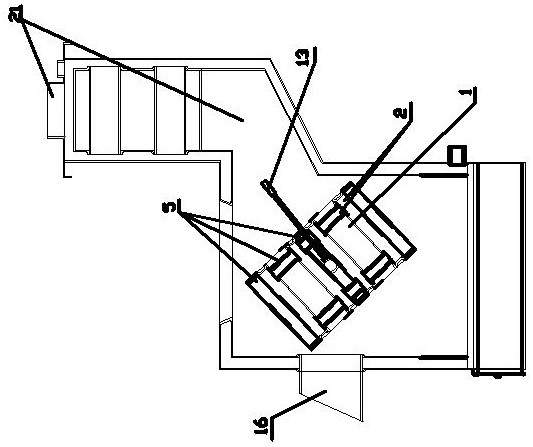

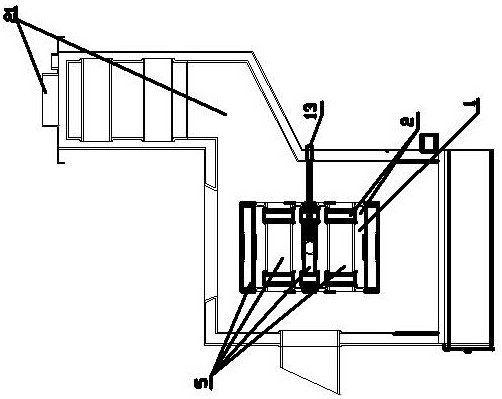

[0036] Embodiment: The structure of the rotary joint mainly includes a base, a rotating shaft, bearings assembled on the rotating shaft in sequence, a constant ring, a motion base, a slewing ring, an O-ring on the motion base, and a stopper The C-shaped buckle of the bearing and the slewing ring. The front and rear edges of the motion base are respectively provided with protrusions of different thicknesses. The protrusions respectively form the steps of the stop bearing and the constant ring. The rotary joint is assembled with the rotating shaft of each component. Inserted into the seat body, the assembly of the rotary joint is more convenient and fast, so as to reduce the operation cost. In addition, the shape of the shaft center portion of the swivel joint is formed such that the swivel joint swivel passage is arranged in the axial direction. The male thread portion is provided at the outer surface of the rotary shaft portion, and the female thread portion is provided at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com