Automatic distillation method and system based on solution saturation temperature and pressure relationship

A technology of pressure and relationship, applied in chemical instruments and methods, distillation separation, separation methods, etc., can solve the problems of low evaporation efficiency, no consideration of the influence of solvent heating rate, and large energy consumption, so as to prevent foaming and ensure distillation The effect of purifying the test index and improving the utilization rate of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

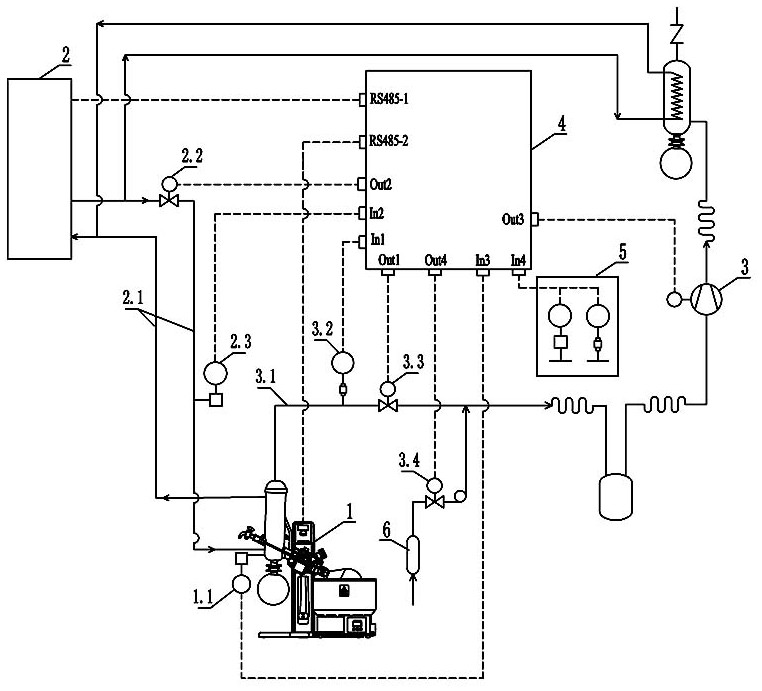

[0039] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

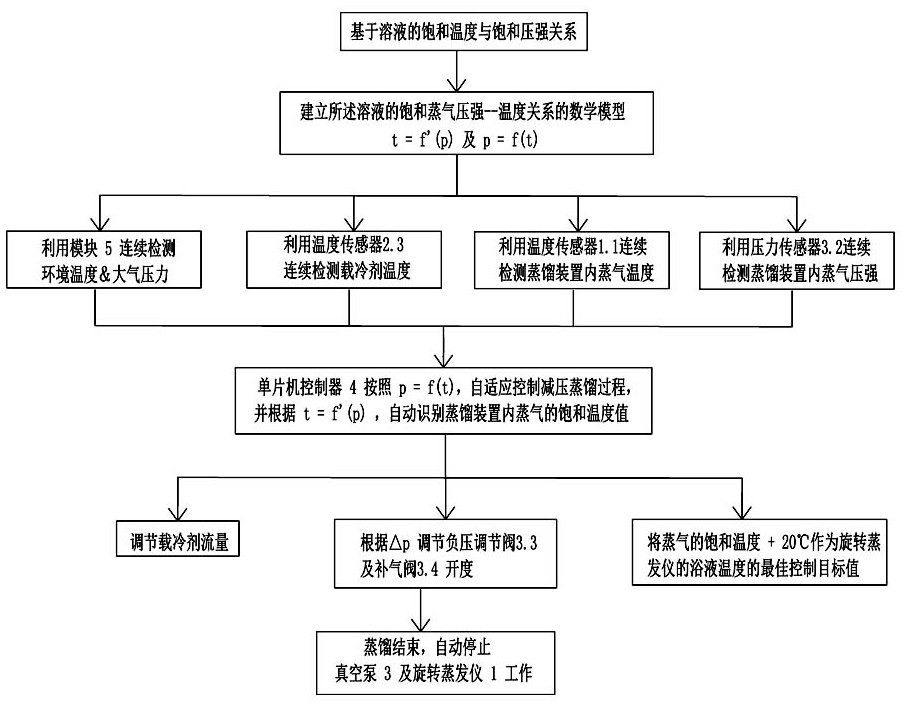

[0040] like figure 1 Shown, the method for automatic distillation based on solution saturation temperature-pressure relation of the present invention, comprises the following steps:

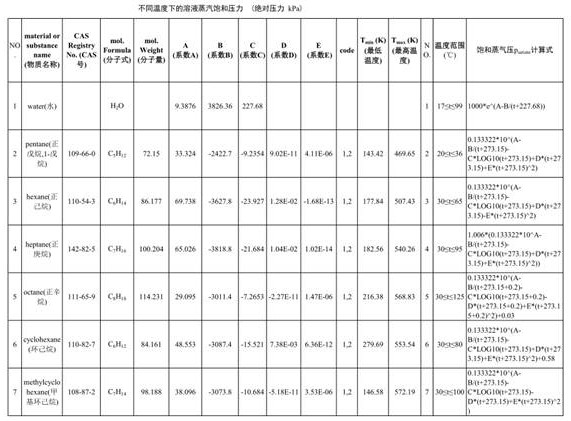

[0041] S1, according to the vapor pressure equation provided in the "Petrochemical Basic Data Handbook" and "Solvent Handbook" (3rd Edition) and "Practical Solvent Handbook" in the "Solution Vapor Pressure and Temperature Relation Table", using the physical property calculation method, Establish the relationship between the saturated vapor pressure of the selected solvent and its tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com