Shimmy tester of elastic shaft coupling

An elastic coupling and testing machine technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of high test accuracy, large output torque, and the output torque can not meet the requirements of elastic coupling, and achieve fast dynamic response. , The effect of large output torque and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

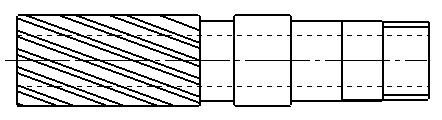

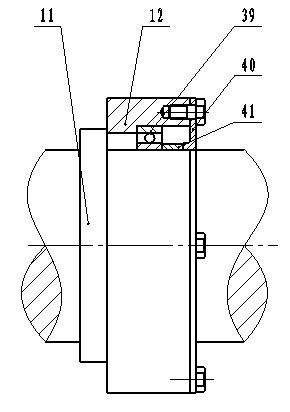

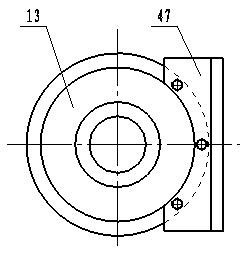

[0029] see figure 1 Summary of the invention: the present invention provides a high-torque multifunctional shimmy testing machine capable of performing elastic coupling static performance test, fatigue test, tension and compression and dynamic torsional swing test, including hydraulic drive components, force sensor 3, ball joint earrings 4, ball joint Seat 5, connecting device and positioning piece for fixing the elastic coupling to be tested; the hydraulic drive component provides the power for tension, compression and torsion tests, and the output end of the hydraulic cylinder 2 of the hydraulic drive component passes through the force sensor 3, ball Hinge clevis 4 and ball hinge seat 5 are connected with connecting device; Said connecting device comprises first connecting device 6, second connecting device 43 and third connecting device 44; The output end of first connecting device 6 is converted by connecting force / motion The mechanism and detection device are connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com