Photography module

An area and elastic element technology, applied in the field of photographic modules, can solve the problems of fatigue at the contact point of the elastic element 200, reduction of the service life of the elastic element 200, absorption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The camera module of the present invention will be described in detail through the following embodiments in conjunction with the accompanying drawings.

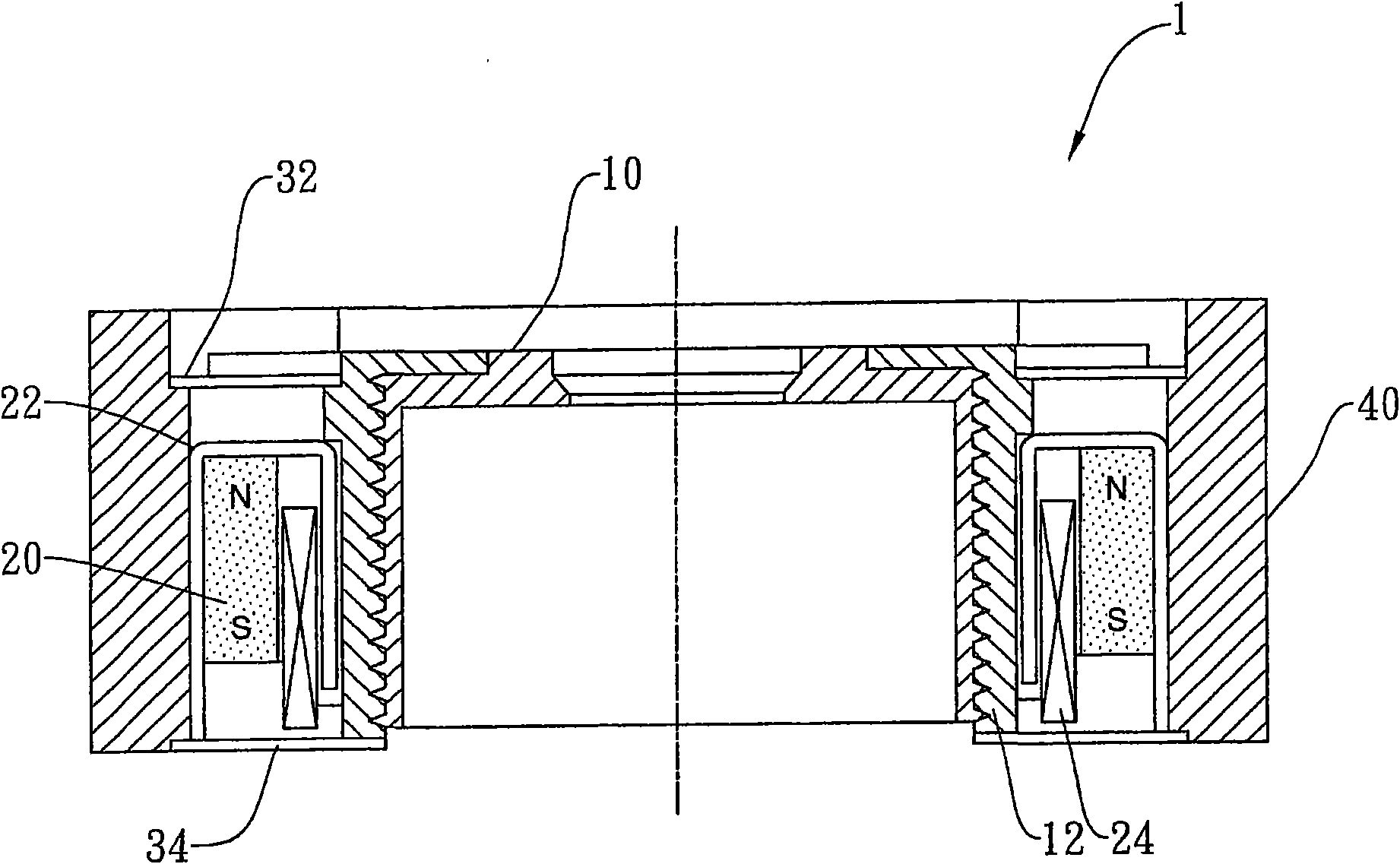

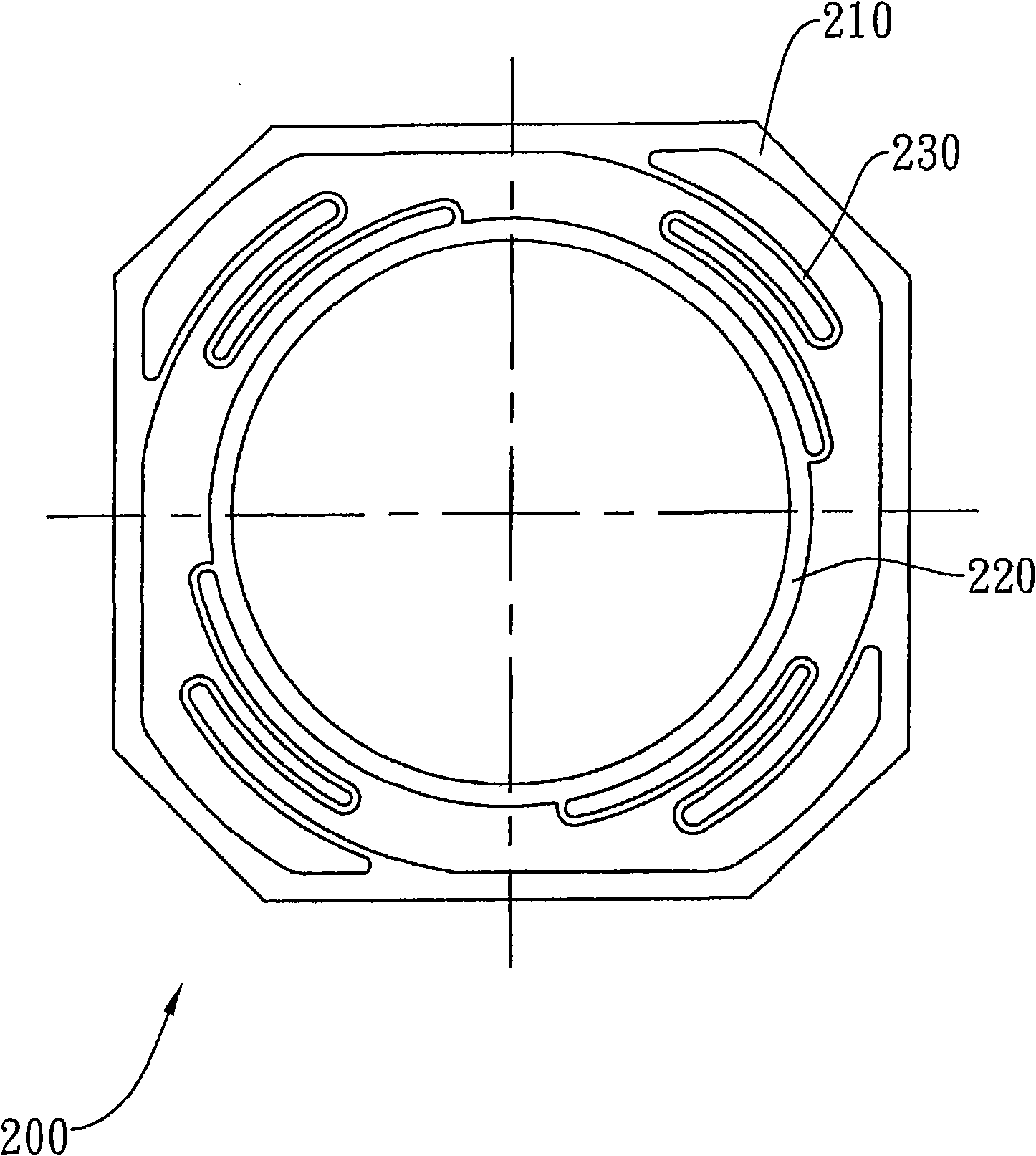

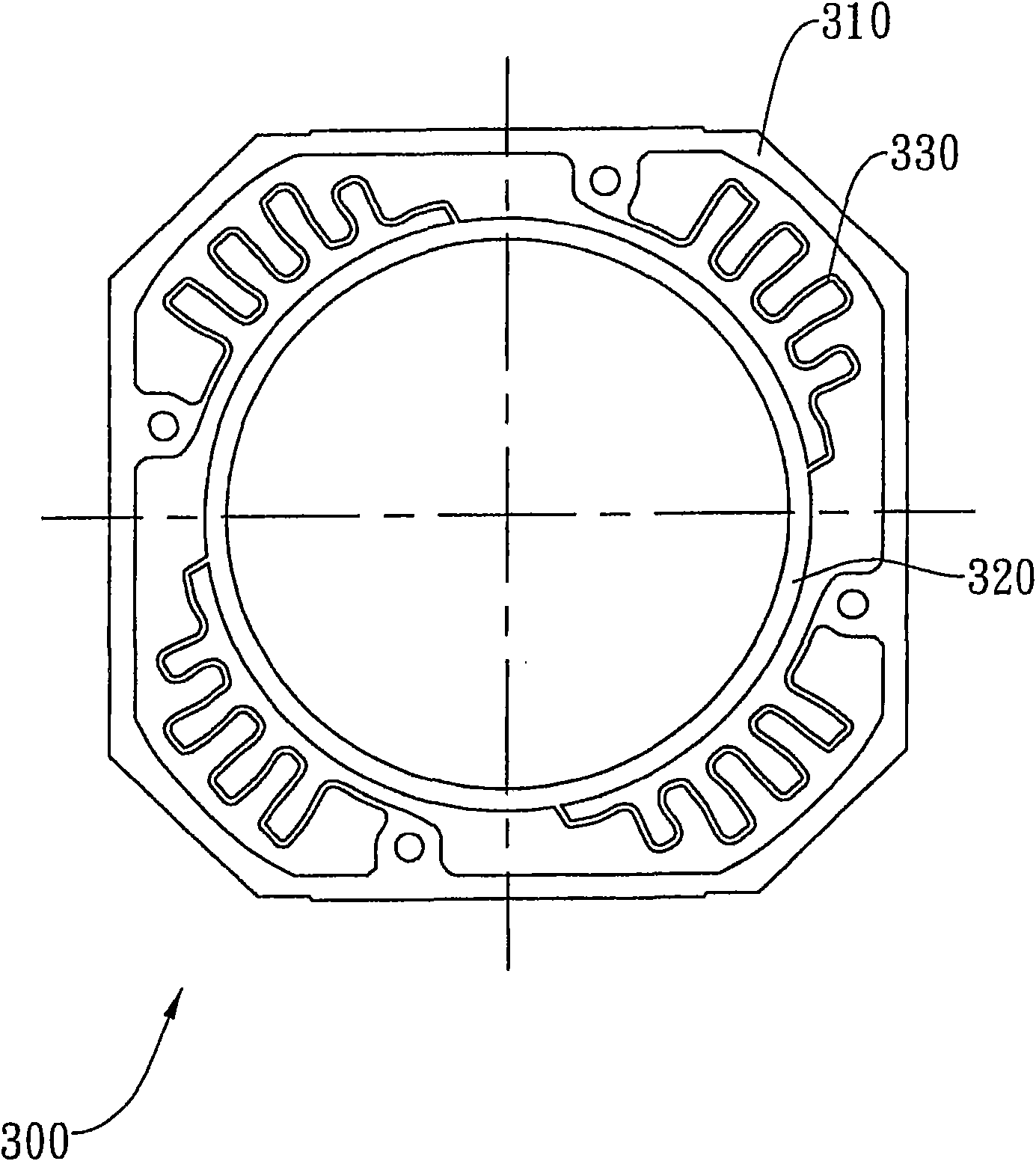

[0033] Figure 5 It is a schematic cross-sectional view of an embodiment of the camera module of the present invention. Figure 5 The camera module 500 includes a lens 501, a lens bearing seat 502, at least one coil 503, at least one yoke (Yoke) 504, at least one magnet 505, at least one insulating sheet 506, a first elastic element 507a and a An elastic element, a seat 508 , an optical filter 509 , a light sensing element 510 , a circuit substrate 511 and an outer cover 512 are formed by the second elastic element 507 b.

[0034] The optical axis of the seat 508 is hollow to form an accommodating space, and the seat 508 is assembled on the circuit board 511, and the light sensing element 510 is arranged on the seat 508 and assembled on the circuit substrate 511 . The optical filter 509 is disposed above the light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com