Method for preparing double-exchange biasing field type spin valve

A technology of bias field and spin valve, which is applied in the manufacture/processing of electromagnetic devices, static memory, instruments, etc., can solve the problems of complicated process, high cost, and degraded giant magnetoresistance performance, so as to simplify the preparation steps and increase the The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for preparing a double exchange bias field type spin valve includes the following steps:

[0027] Step 1: Using a thin film deposition process and under the action of an external magnetic field, a double exchange bias field type spin valve is prepared.

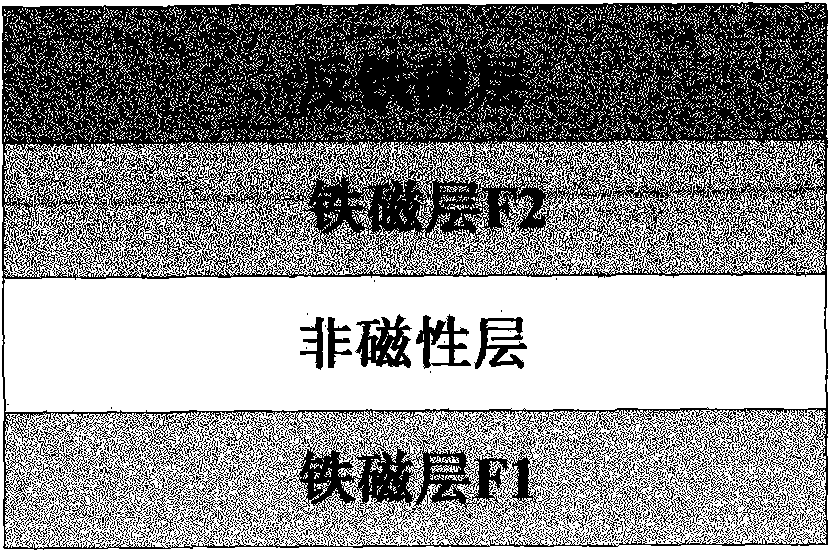

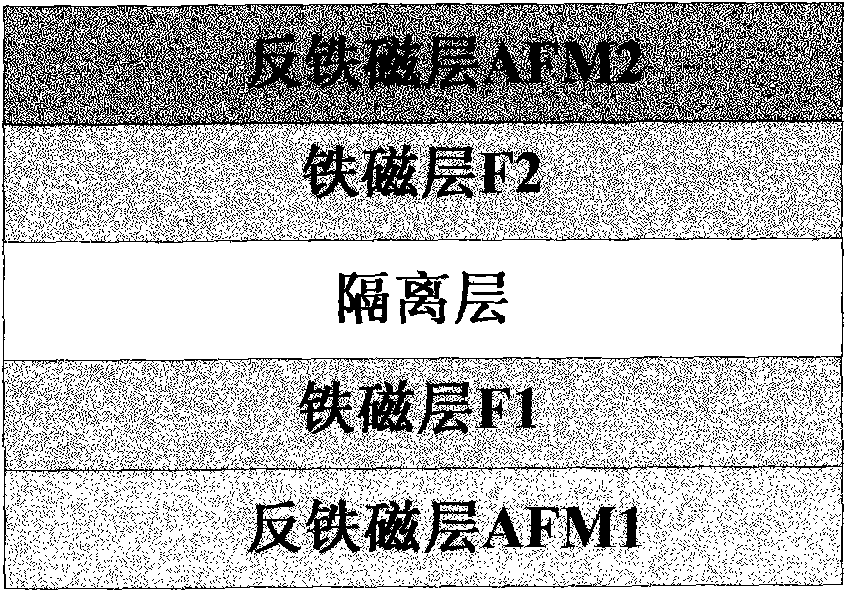

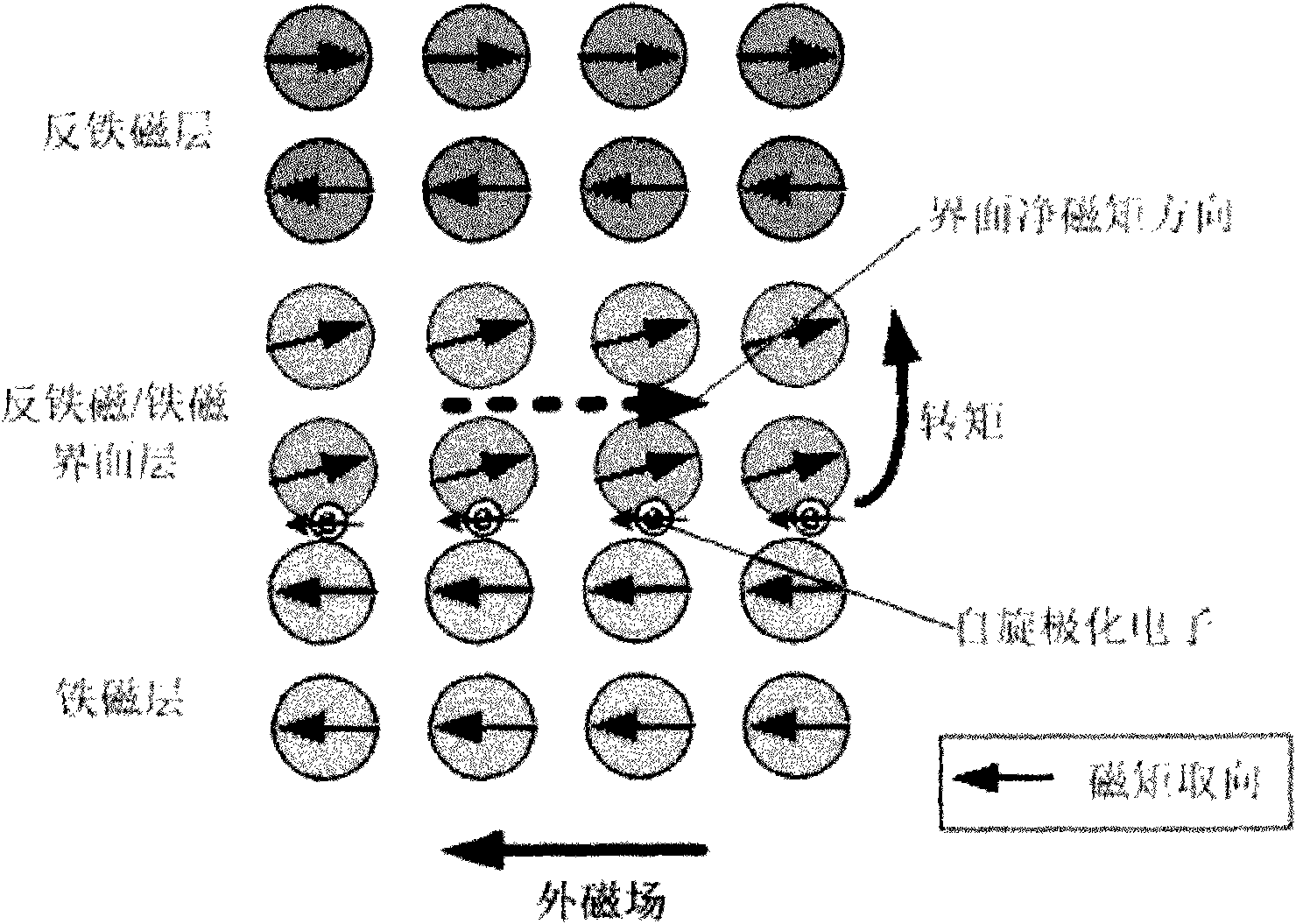

[0028] The structure of the double exchange bias field type spin valve is as figure 2 As shown, from the top of the substrate, there are buffer layer, antiferromagnetic layer AFM1, ferromagnetic layer F1, isolation layer, ferromagnetic layer F2, antiferromagnetic layer AFM2 and cover layer in order. The substrate can be Si substrate or glass substrate, the buffer layer material is Ta, the antiferromagnetic layer AFM1 and the antiferromagnetic layer AFM2 material are FeMn, NiMn, IrMn, PtMn or NiO, the ferromagnetic layer F1 and the ferromagnetic layer F2 The material is Ni, Fe, Co or Ni / Fe / Co alloy, the material of the isolation layer is Cu, and the material of the cover layer is Ta.

[0029] The external magnetic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com