Electromagnetic core with extension edge insulating layer

A technology of insulating layer and electromagnetic core, which is applied in the direction of winding insulation shape/style/structure, magnetic circuit shape/style/structure, etc., can solve the problems of cost increase, motor efficiency reduction, electromagnetic wire consumption increase, etc., to reduce the length , Saving electromagnetic wires and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

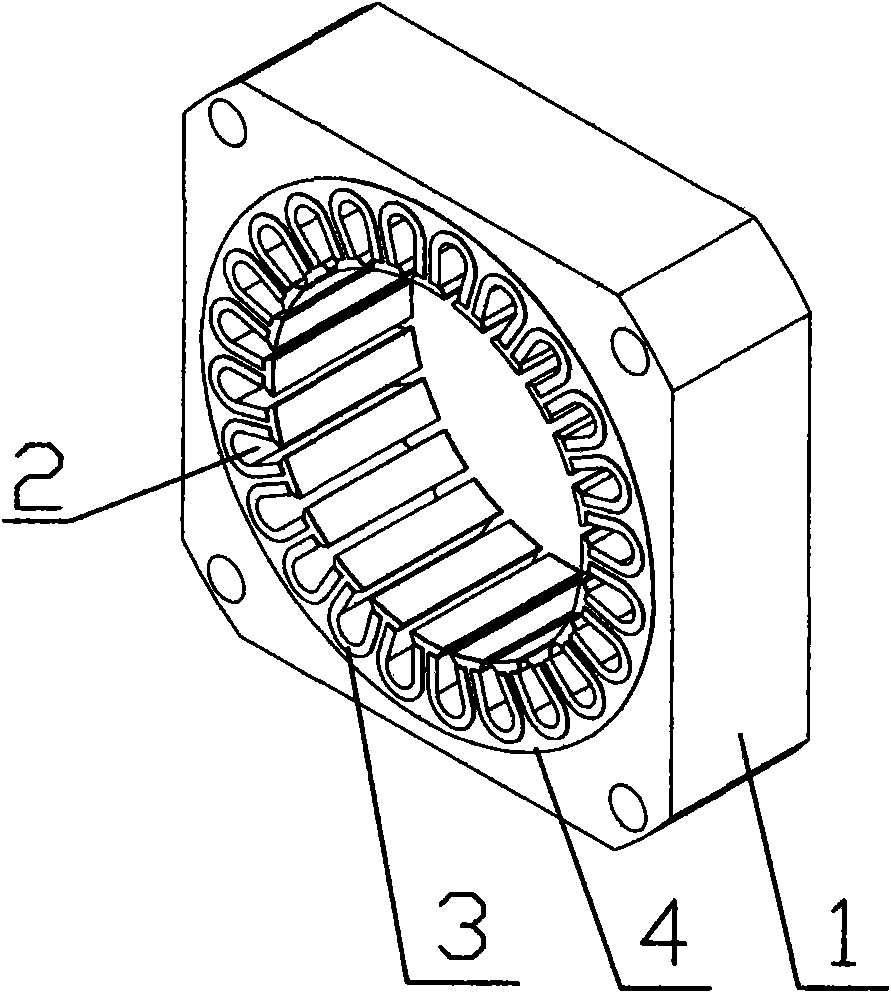

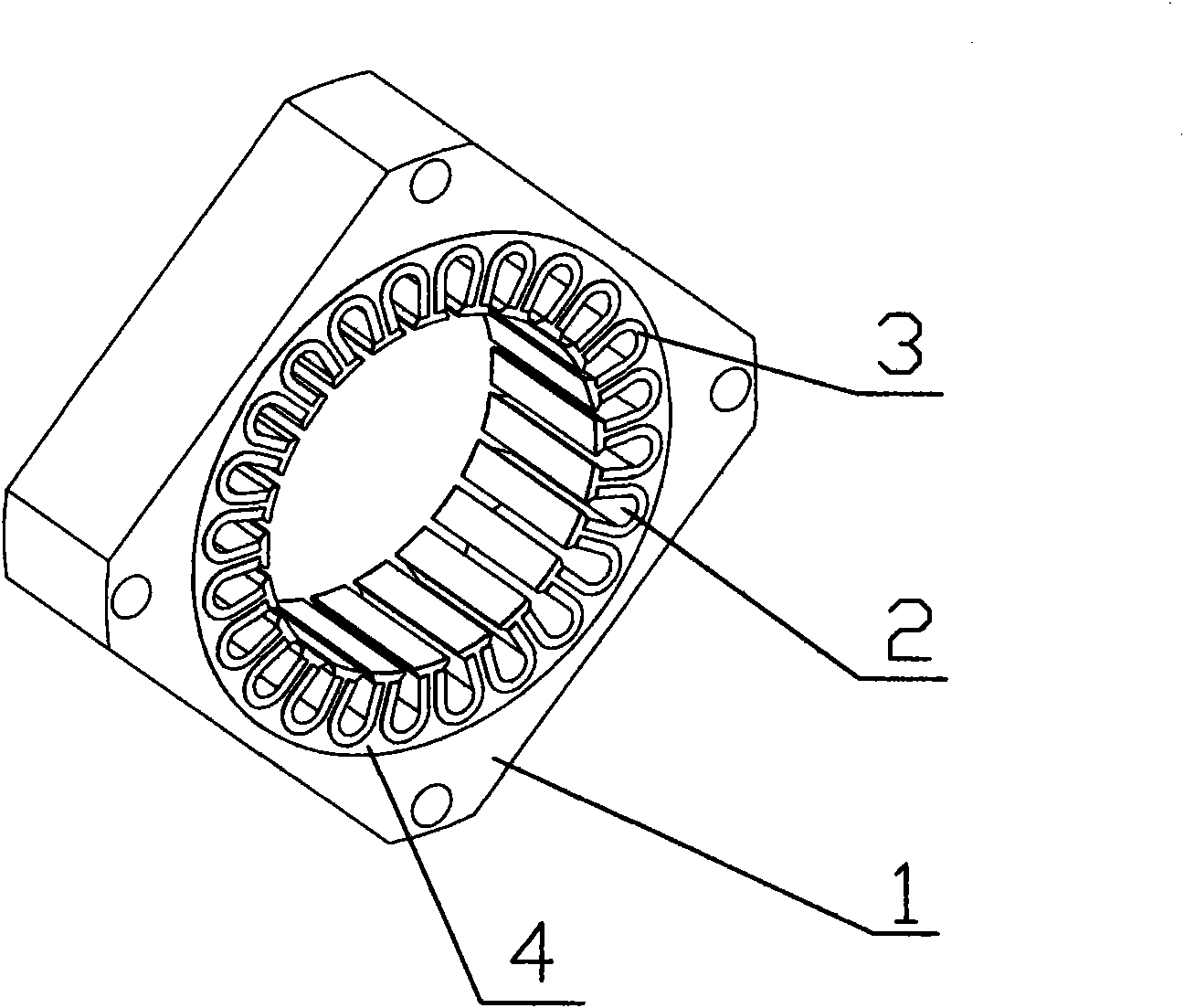

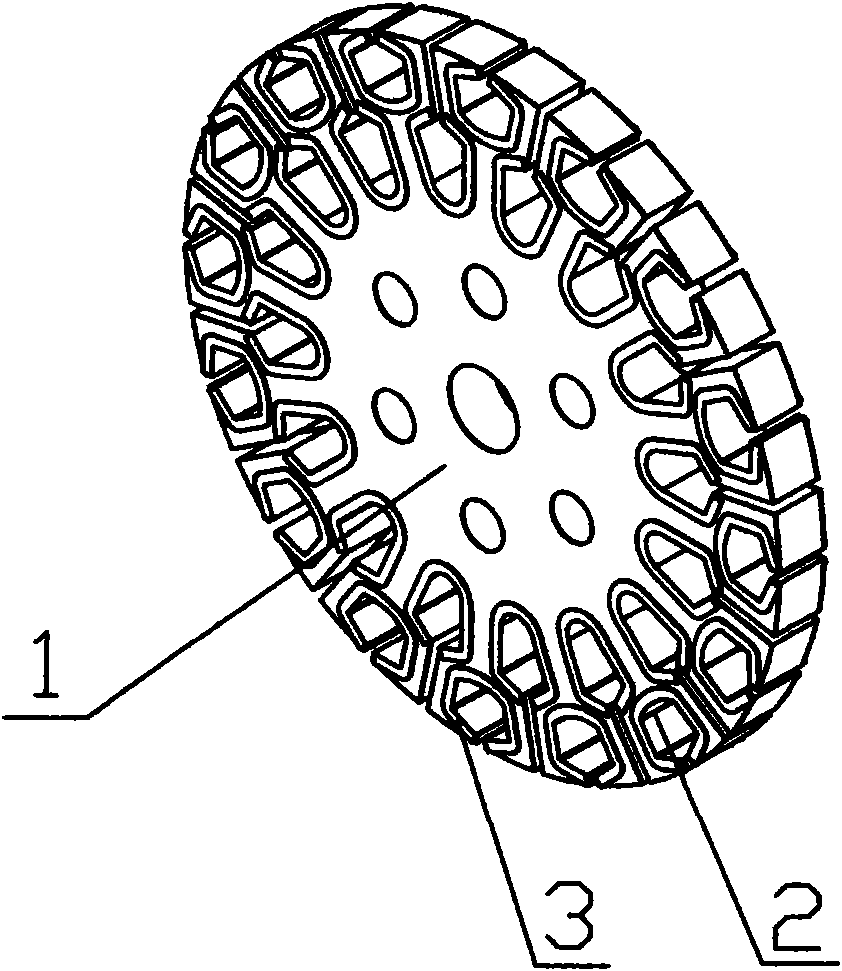

[0016] Such as Figure 1 to Figure 4 As shown, the electromagnetic core with the epitaxial insulating layer includes an electromagnetic core 1 and an insulating layer 2 arranged on the inner side of the electromagnetic core 1, and an insulating layer 3 is provided on the outer end surface of the electromagnetic core 1, and the outer side insulating layer 3 A laminated connection is formed with the inner side insulating layer 2 .

[0017] In this embodiment, the electromagnetic core 1 is provided with several grooves, and an insulating layer 2 is arranged in the grooves by a thermoforming machine, and the insulating layer 2 extends outward to form an extension edge 3, and the extension edge 3 of the insulation layer covers the Part of the end face of the magnetic core. As another embodiment, the outer end surface of the electromagnetic core 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com