Needle probe for cooling operation and cooling operation system

A detector and function technology, applied in the field of needle detectors for cooling operation and cooling operating system, to achieve the effect of effective cooling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Embodiments of the present invention will be described below with reference to the drawings.

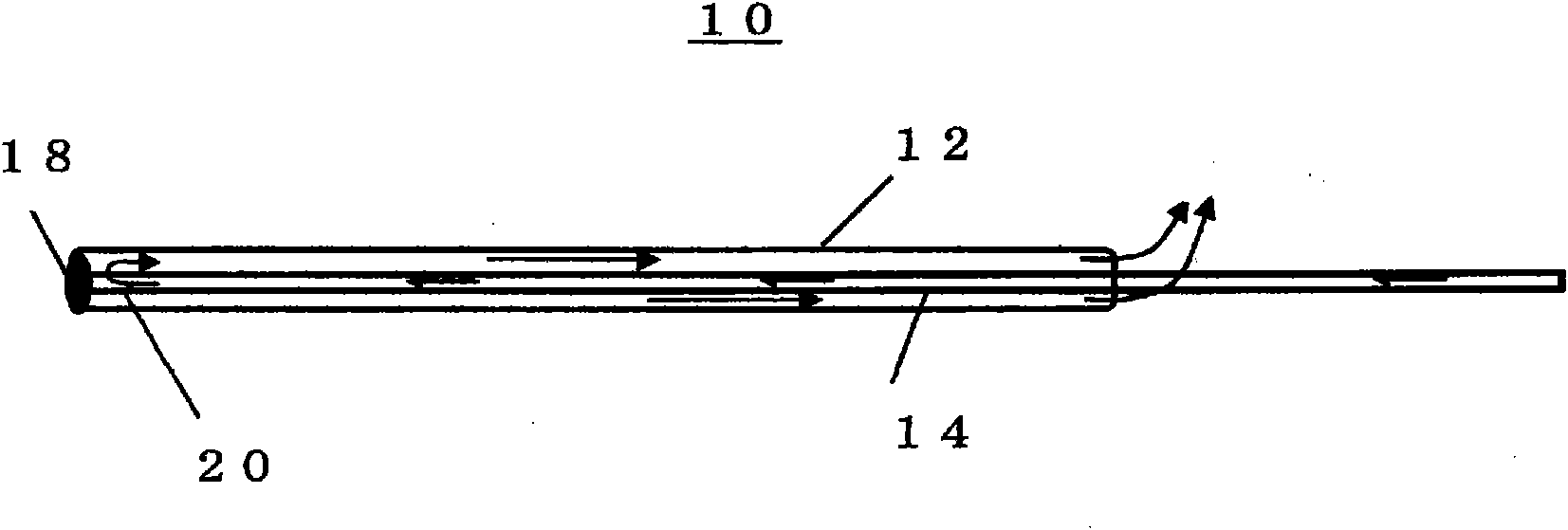

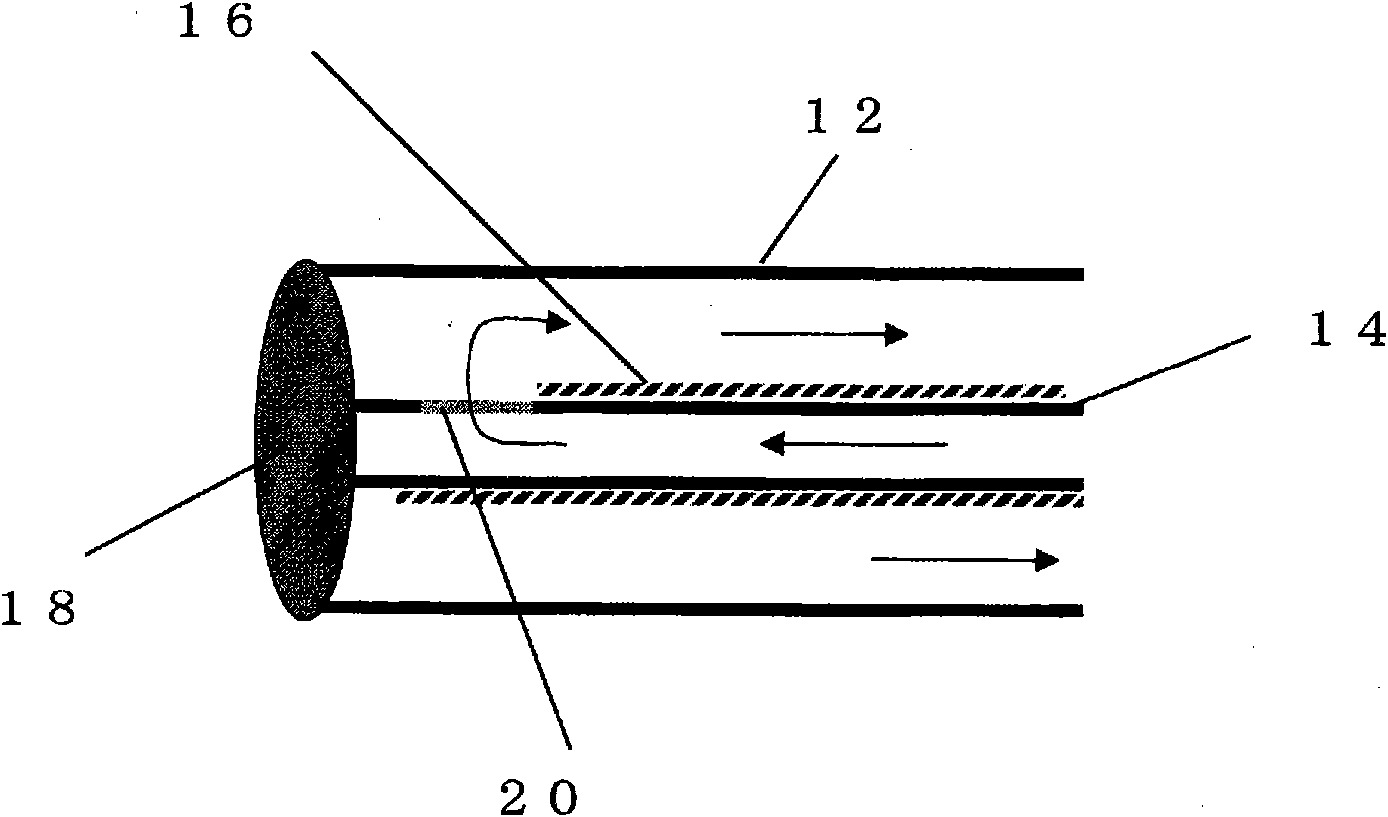

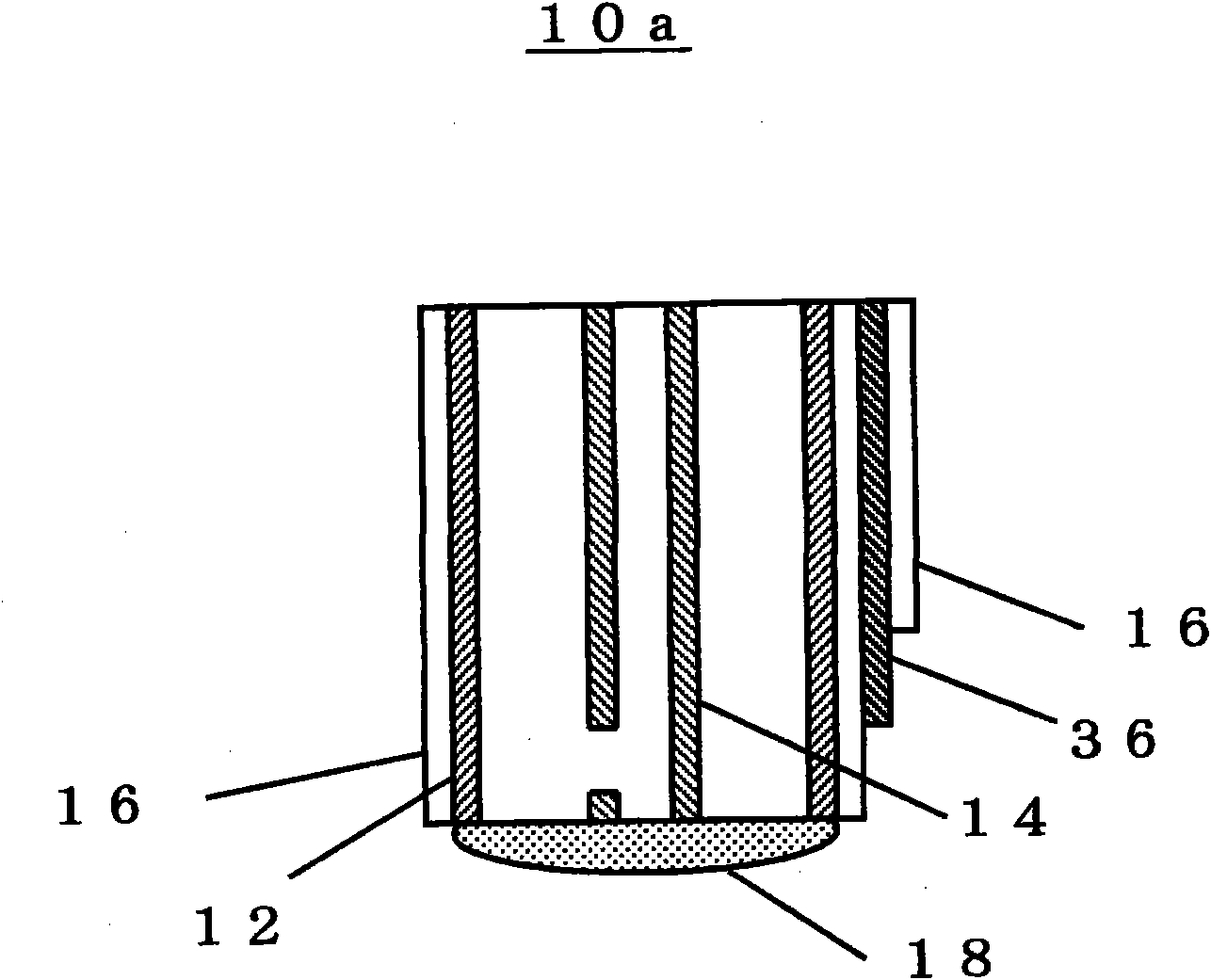

[0068] refer to figure 1 and figure 2 The needle probe for cooling operation described in the first example of this embodiment will be described.

[0069] exist figure 1 The needle probe 10 for cooling operation described in the first example of the present embodiment, whose schematic structure is illustrated in FIG. 2 , has a first cylindrical body 14 and a second cylindrical body 12 .

[0070] The first cylindrical body 14 and the second cylindrical body 12 are made of different kinds of thin metals, and are extended while being electrically insulated from each other.

[0071] The first cylindrical body 14 and the second cylindrical body 12 have the basic function of the detector that can make the refrigerant circulate, and also have the function of the compensating wire (core wire) of the thermocouple. As long as this function is played, it can be used. metal material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com