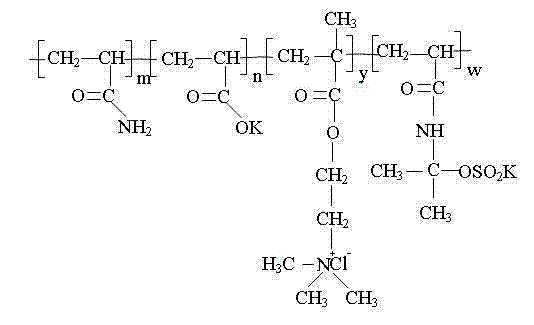

Method for preparing acid fracturing, temperature-controlled and variable-viscosity polymer and polymer cross-linked body

A polymer and acid fracturing technology, applied in the field of acid fracturing of oil and gas wells, can solve the problems of low viscosity, acid fluid loss and acid-rock reaction speed gap, etc., to ensure effective reaction, reduce damage, and improve acid fracturing effect. and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: a kind of preparation method of the polymer that is used for acid fracturing temperature control becomes viscous, comprises the following steps:

[0049] 1) Put AMPS and AA into the deionized water in the reactor in turn, stir until completely dissolved, slowly add carbonate under stirring, the amount of carbonate added is 13% to 16% of the total weight of AMPS and AA %, stirred until completely dissolved; the weight ratio of AMPS, AA and deionized water is:

[0050] AMPS 43~55

[0051]AA 1~5

[0052] Deionized water 254~280;

[0053] The carbonate in this embodiment can be one or both of potassium carbonate, potassium bicarbonate, sodium carbonate, sodium bicarbonate, ammonium carbonate, ammonium bicarbonate, etc. used in combination, such as potassium carbonate and ammonium carbonate (potassium carbonate and ammonium carbonate weight ratio is 2:1);

[0054] 2) Add acrylamide accounting for 26% to 30% of the total amount to the solution obtained in st...

Embodiment 2

[0066] Embodiment 2: A kind of preparation method of the polymer cross-linked body that is used for acid fracturing temperature control becomes viscous, comprises the following steps:

[0067] 1) Put AMPS and AA into the deionized water in the reaction kettle in turn, stir until completely dissolved, slowly add potassium carbonate accounting for 13% of the total material (AMPS and AA total weight) under stirring, and stir until completely dissolved; AMPS , The weight ratio of AA to deionized water is:

[0068] AMPS 43

[0069] AA 1

[0070] Deionized water 280;

[0071] 2) Add acrylamide (AM) accounting for 26% (by weight) of the total amount to the solution obtained in step 1), and stir evenly until completely dissolved;

[0072] 3) Add 0.3% (by weight) of methacryloyloxyethyltrimethylammonium chloride (DMC) to the solution obtained in step 2), stir well, and control the temperature of the obtained solution at 6℃~8℃, adjust the pH value to 7.4~7.8; if the pH value is high...

Embodiment 3

[0093] Embodiment 3: A kind of preparation method of the polymer cross-linked body that is used for acid fracturing temperature control becomes viscous, comprises the following steps:

[0094] 1) Put AMPS and AA into the deionized water of the reactor in turn, stir until completely dissolved, slowly add potassium bicarbonate accounting for 13% of the total material (AMPS and AA total weight) under stirring, and stir until completely dissolved; The weight ratio of AMPS, AA and deionized water is:

[0095] AMPS 43

[0096] AA 1

[0097] Deionized water 280;

[0098] 2) Add acrylamide (AM) accounting for 26% (by weight) of the total amount to the solution obtained in step 1), and stir evenly until completely dissolved;

[0099] 3) Add 0.3% (by weight) of methacryloyloxyethyltrimethylammonium chloride (DMC) to the solution obtained in step 2), stir well, and control the temperature of the obtained solution at 6℃~8℃, adjust the pH value to 7.4~7.8; if the pH value is higher tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com