Device for preparing nano fibers with ordered arrangement and cross structures

A technology of orderly arrangement of nanofibers, applied in fiber processing, textiles and papermaking, clustering of newly extruded filaments, etc., to achieve good safety, small diameter and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

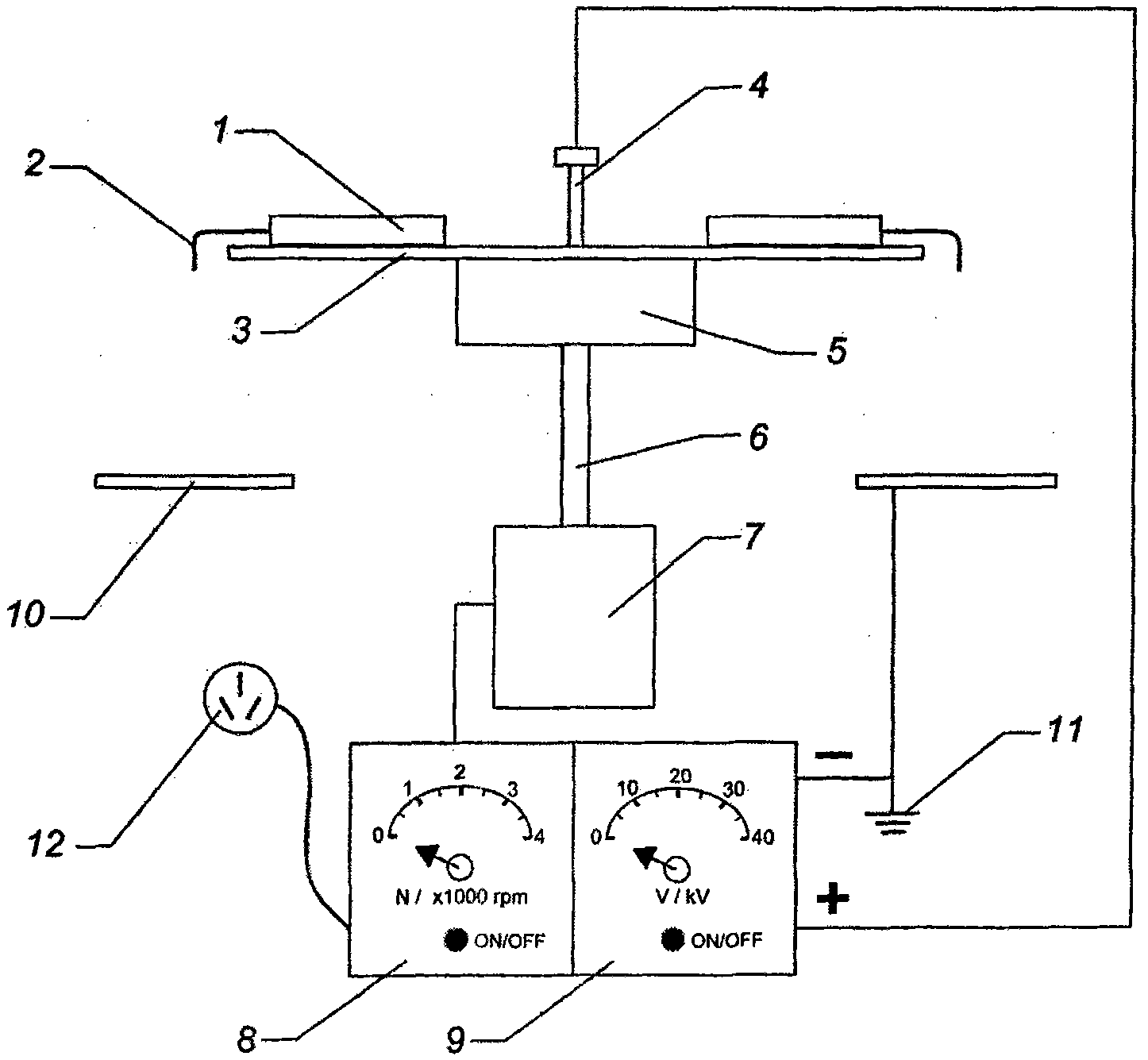

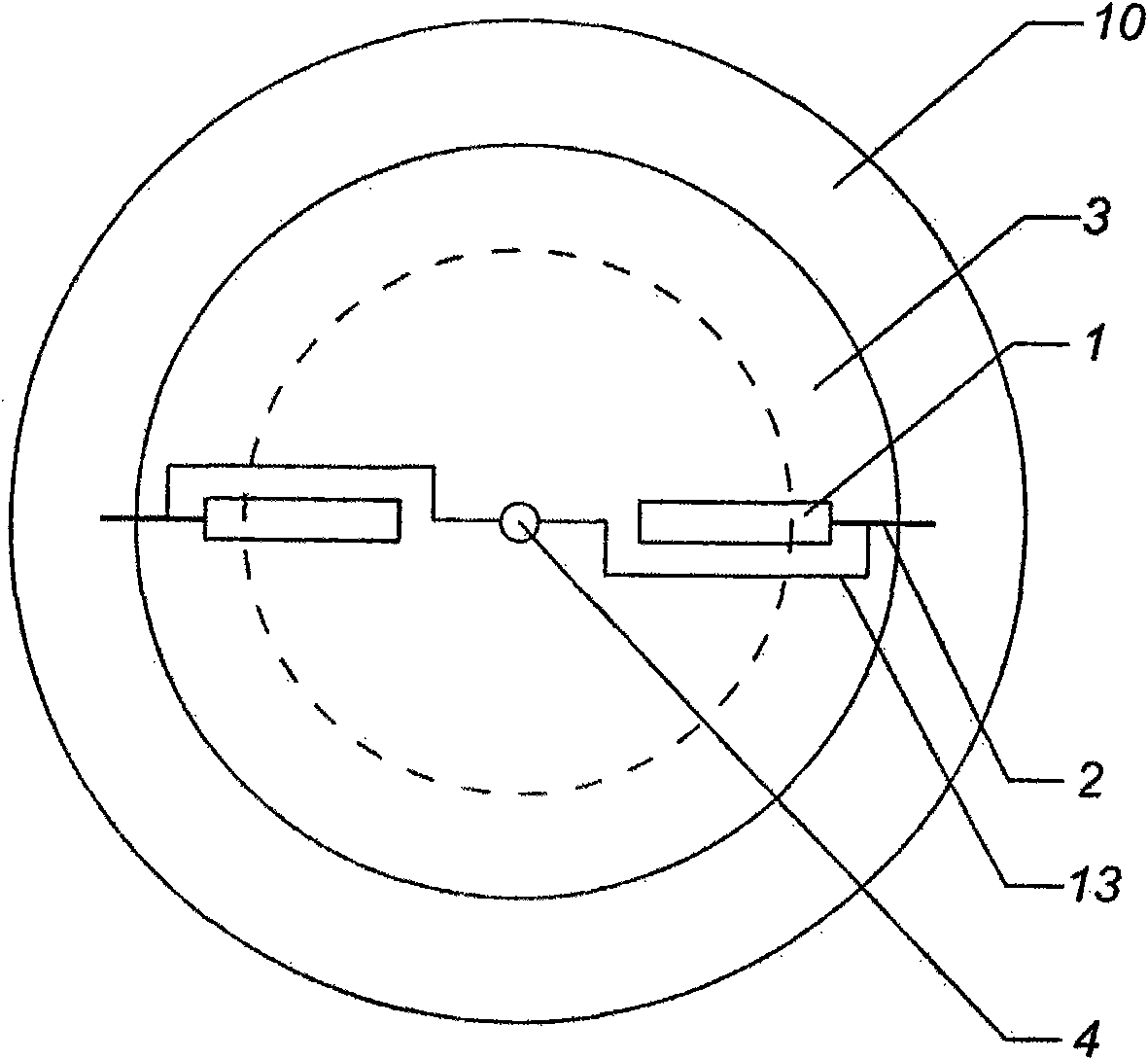

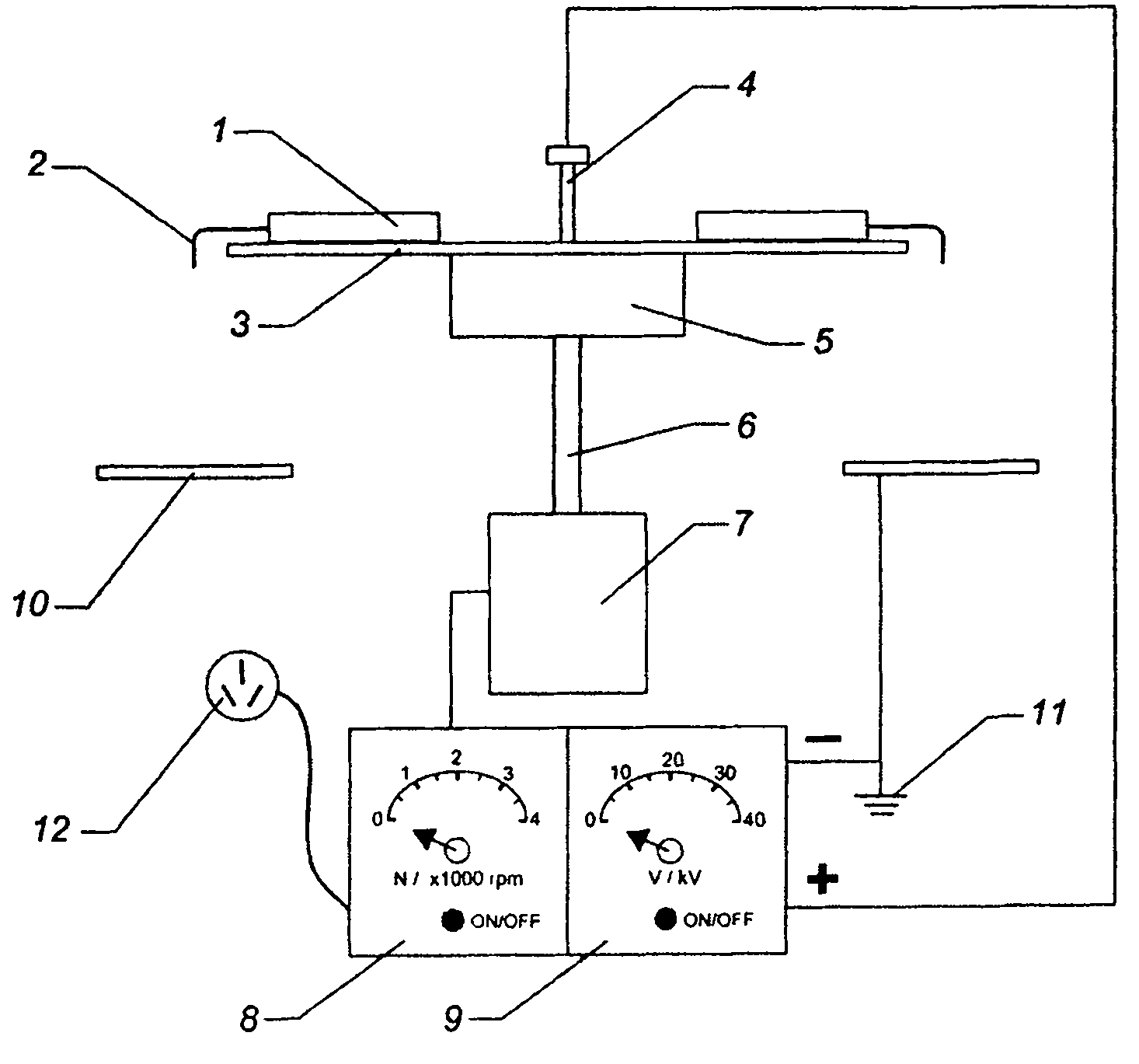

[0014] Example: Preparation of ordered electrospun fibers

[0015] The spinning solution selected in this embodiment is a polystyrene (PS) solution with a mass percentage of 18 wt%. First, 1.8 g of PS (molecular weight is 250,000) particles are slowly added to 8.2 g of tetrahydrofuran (THF) and N under magnetic stirring. In a mixed solution of N-dimethylformamide (DMF) (the mass ratio of THF to DMF is 1:1), magnetic stirring at room temperature for 4 hours, and then standing for 0.5 hours, a uniform and transparent 18wt% PS static electricity can be obtained. Spinning precursor solution; then the positive pole of the high-voltage power supply is connected to the metal rod 4, and the negative pole is connected to the annular metal collecting pole 10 and grounded 11; the position of the spinning solution container 1 (syringe) on the insulating rotating disk 3 is adjusted so that the processed The horizontal distance between the tip of the hollow stainless steel needle 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com