a y 2 o 3 Nanopowder and its preparation method

A nano-powder, micron-scale technology, applied in the direction of nanotechnology, chemical instruments and methods, rare earth metal oxides/hydroxides, etc., can solve the problem of high activity of yttrium ion phase grains, inability to be affected by aluminum ions, and easy aggregation. Large and other problems, achieve good industrial application prospects, overcome the difficulty of concentration gradient, and reduce the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

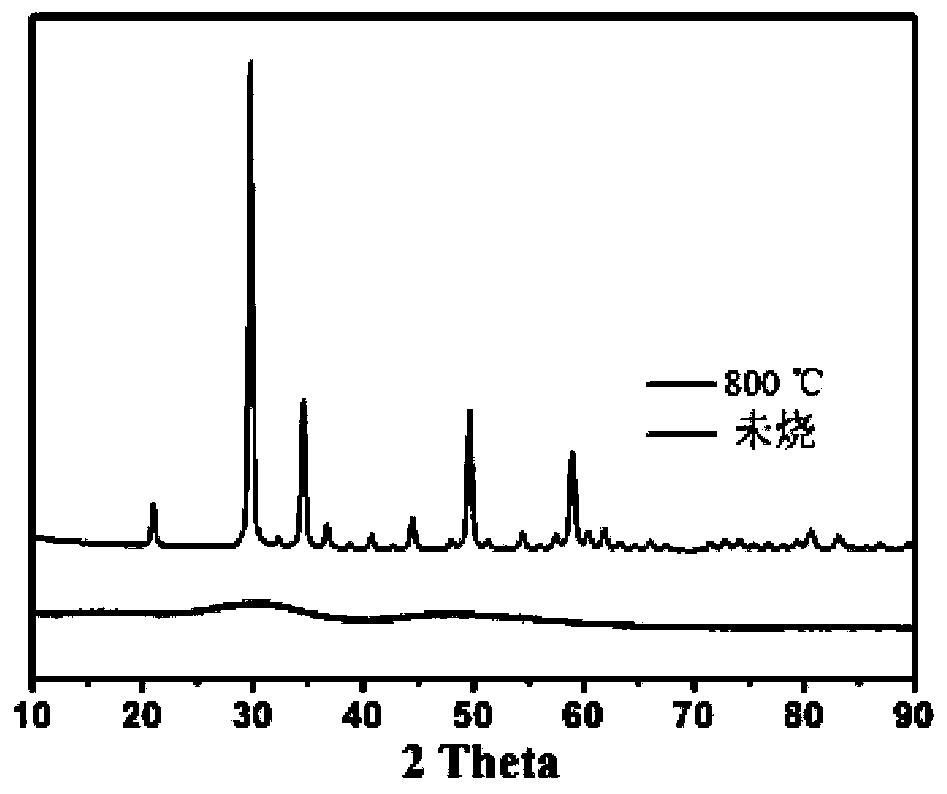

[0036] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (mass fraction is 65%), diluted with water to form 0.01mol / L Y(NO 3 ) 3 clear solution, and micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is the stoichiometric ratio of 2:3; while stirring, 15g of hexamethylenetetramine, a certain amount of (NH 4 ) 2 SO 4 Static stabilizer added above Y (NO 3 ) 3 and the added dispersant dose is the theoretical nanometer Y 2 o 31% of mass. , stirred until the solution was completely transparent, placed in a microwave oven with a frequency of 2.45 GHz and an output power of 1100 W and a model BS1200 for 1.5 h of microwave irradiation, and then quenched the precursor synthesized by microwave in an ice-water mixture for 0.5 h, followed by Wash with deionized water and absolute ethanol for 3 times and centrifuge to obtain the precursor precipitate, dry it at 80°C for 2...

Embodiment 2

[0038] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (mass fraction is 65%), diluted with water to form 0.02mol / L Y(NO 3 ) 3 clear solution of micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is the stoichiometric ratio of 2:3; while stirring, 60g of hexamethylenetetramine, a certain amount of (NH 4 ) 2 SO 4 Static stabilizer and PVP are added to the above Y(NO 3 ) 3 In the clear solution of , and the added dispersant dose is the theoretical nanometer Y 2 o 3 3% of mass. , stirred until the solution was completely transparent, placed in a microwave oven with a frequency of 2.45GHz and an output power of 1100W and a model BS1200 for 1.6h of microwave irradiation, and then quenched the precursor synthesized by microwave in an ice-water mixture for 0.7h, and then used Wash with deionized water and absolute ethanol for 3 times and centrifuge to obtain the p...

Embodiment 3

[0040] A certain mass of micron-scale (4N)Y 2 o 3 The powder (purity 99.99%) is heated and completely dissolved in excess nitric acid (65% by mass fraction), diluted with water to form 0.03mol / L Y(NO 3 ) 3 clear solution of micron (4N)Y 2 o 3 The ratio of dissolving with nitric acid (mass fraction is 65%) is the stoichiometric ratio of 3:4; while stirring, 75g of hexamethylenetetramine, a certain amount of (NH 4 ) 2 SO 4 Static stabilizer and PEG40000 added above Y(NO 3 ) 3 In the clear solution of , and the added dispersant dose is the theoretical nanometer Y 2 o 3 5% of the mass. , adding the above Y(NO 3 ) 3 After stirring until the solution is completely transparent, put it in a microwave oven with a frequency of 2.45 GHz and an output power of 1100 W and a model BS1200 for 1.6 h of microwave irradiation, and then quench the precursor synthesized by microwave in an ice-water mixture for 1 h , washed with deionized water and absolute ethanol three times and cen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com