An electrospun membrane with adsorption and filtration function and its preparation method and application

An electrospinning and spinning technology, which is applied in the field of smog protective film materials and its preparation, can solve the problems of low adsorption rate and poor air permeability, and achieve the effects of long storage period, low cost and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the haze protective electrospun membrane is prepared by the following method, which specifically includes the following steps:

[0048] 1. Dissolve 2.2g polylactic acid-glycolic acid in 20mL hexafluoroisopropanol solvent, stir magnetically at room temperature for 12h, and obtain a spinning solution with a polymer concentration of 11% (w / v), wherein polylactic acid-glycolic acid and The mass ratio of polycaprolactone is 1:0.

[0049] 2. The solution was electrospun, with a stainless steel roller as the receiving device, the voltage was 20KV, the receiving distance was 20cm, the spinning liquid inflow rate was 10mL / h, and the spinning was 5h. A film with a thickness of about 250 μm was obtained.

[0050] 3. Freeze-dry the obtained fiber film in a refrigerator for 8 hours, and then dry it in a vacuum oven for 72 hours to ensure that the residual solvent is fully volatilized.

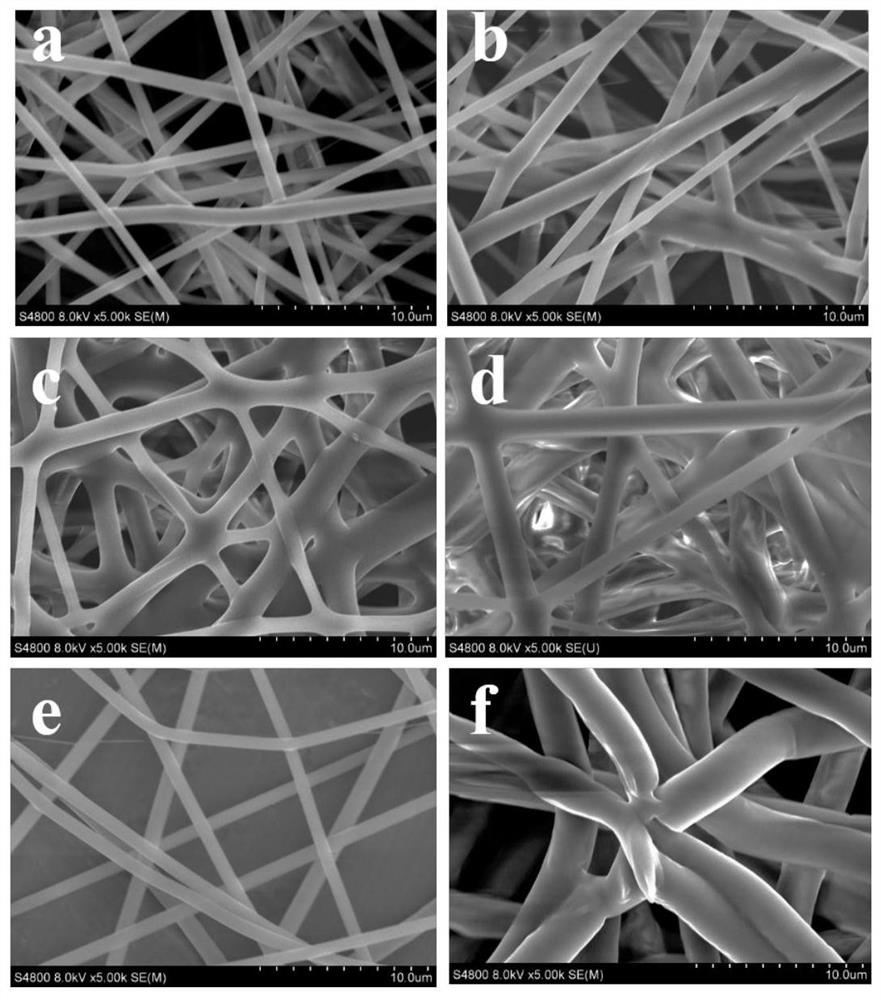

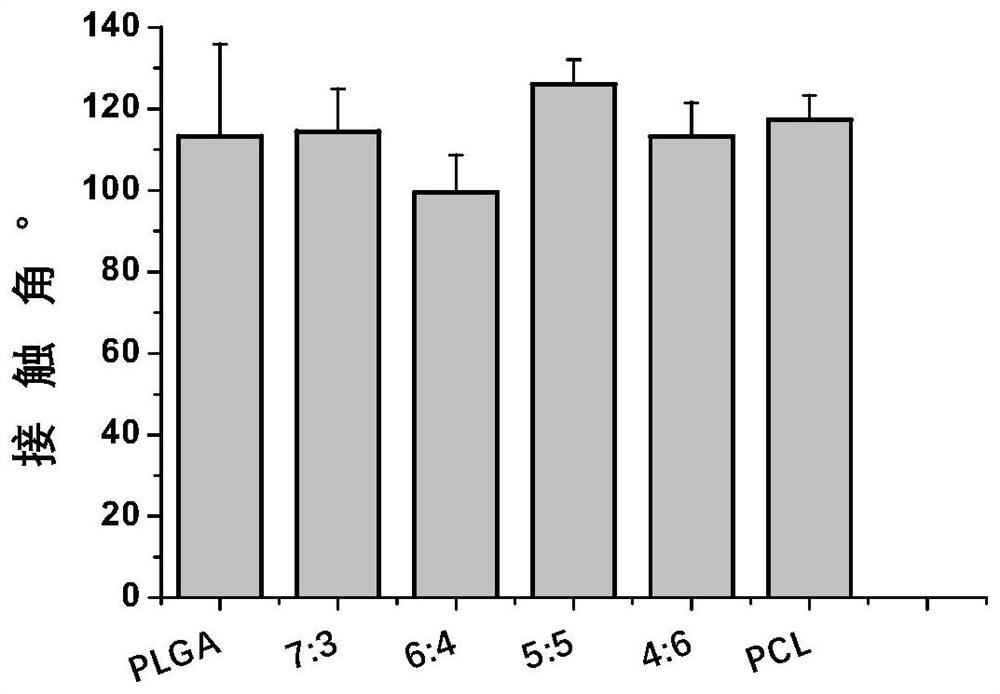

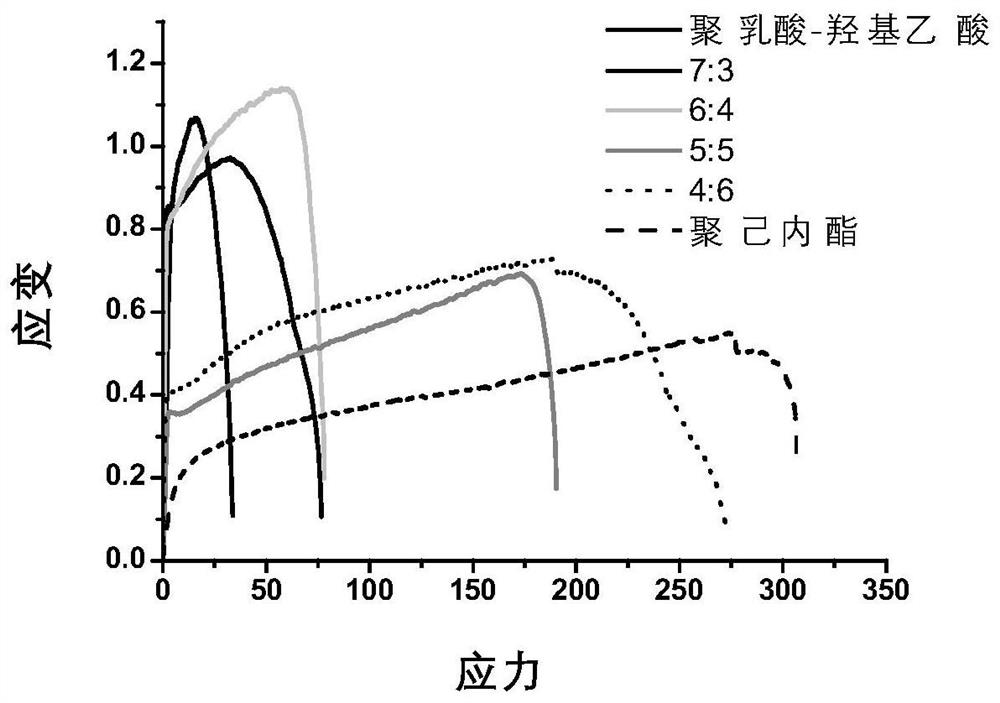

[0051] Scanning electron microscope observation is carried out to the elect...

Embodiment 2

[0055] In this embodiment, the haze protective electrospun membrane is prepared by the following method, which specifically includes the following steps:

[0056] 1. Dissolve 3.85g polylactic acid-glycolic acid and 1.65g polycaprolactone in 50ml hexafluoroisopropanol solvent, stir magnetically at room temperature for 12h to obtain a spinning solution with a polymer concentration of 11% (w / v), The mass ratio of polylactic acid-glycolic acid to polycaprolactone is 7:3.

[0057] 2. The solution was electrospun, with a stainless steel flat table as the receiving device, the voltage was 20KV, the receiving distance was 20cm, the spinning liquid inflow rate was 10mL / h, and the spinning was 5h. A film with a thickness of about 250 μm was obtained.

[0058] 3. Freeze-dry the obtained fiber film in a refrigerator for 8 hours, and then dry it in a vacuum oven for 72 hours to ensure that the residual solvent is fully volatilized.

[0059] Scanning electron microscope observation is car...

Embodiment 3

[0063] In this embodiment, the haze protective electrospun membrane is prepared by the following method, which specifically includes the following steps:

[0064] 1. Dissolve 3.3g polylactic acid-glycolic acid and 2.2g polycaprolactone in 50mL hexafluoroisopropanol solvent, stir magnetically at room temperature for 12h, and obtain a spinning solution with a polymer concentration of 11% (w / v), The mass ratio of polylactic acid-glycolic acid to polycaprolactone is 6:4.

[0065] 2. The solution was electrospun, with a stainless steel flat table as the receiving device, the voltage was 20KV, the receiving distance was 20cm, the spinning liquid inflow rate was 10mL / h, and the spinning was 5h. A film with a thickness of about 250 μm was obtained.

[0066] 3. Freeze-dry the obtained fiber film in a refrigerator for 8 hours, and then dry it in a vacuum oven for 72 hours to ensure that the residual solvent is fully volatilized.

[0067] Scanning electron microscope observation is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com