Small-diameter boron nitride nanotube and preparation method thereof

A boron nitride nanotube and small-diameter technology, which is applied in the field of nanomaterials, can solve the problems of complex preparation process, high reaction temperature, and high cost of raw materials, and achieve the effects of lower reaction temperature, simple preparation method, and improved matrix performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the small-diameter uniform boron nitride nanotube of the present invention comprises the following steps:

[0027] Step (1), put the weighed boron oxide powder in the zirconia ball milling tank, and add an appropriate amount of zirconia grinding balls, vacuumize and introduce an inert protective atmosphere, adopt the mode of forward and reverse alternating operation, ball mill 0.5~ After 12 hours, a uniformly mixed solid powder with a particle size of about 2-10 microns was obtained.

[0028] In step (2), the solid powder obtained in step (1) is placed in a porcelain boat, and the porcelain boat is placed in a tubular atmosphere protection annealing furnace, and the temperature is raised from normal temperature under the protection of 20-100mL / min inert protection atmosphere, The heating rate is 5-10°C / min. When the temperature rises to 300-500°C, the inert protective atmosphere valve is closed, and high-purity ammonia gas is introduced at a fl...

Embodiment 1

[0032] In step (1), put the weighed boron oxide powder in a zirconia ball mill jar, and add an appropriate amount of zirconia grinding balls, vacuumize and feed nitrogen gas, and use the forward and reverse alternate operation mode, and ball mill for 12 hours to obtain Mixed uniform solid powder, the particle size is about 2-10 microns.

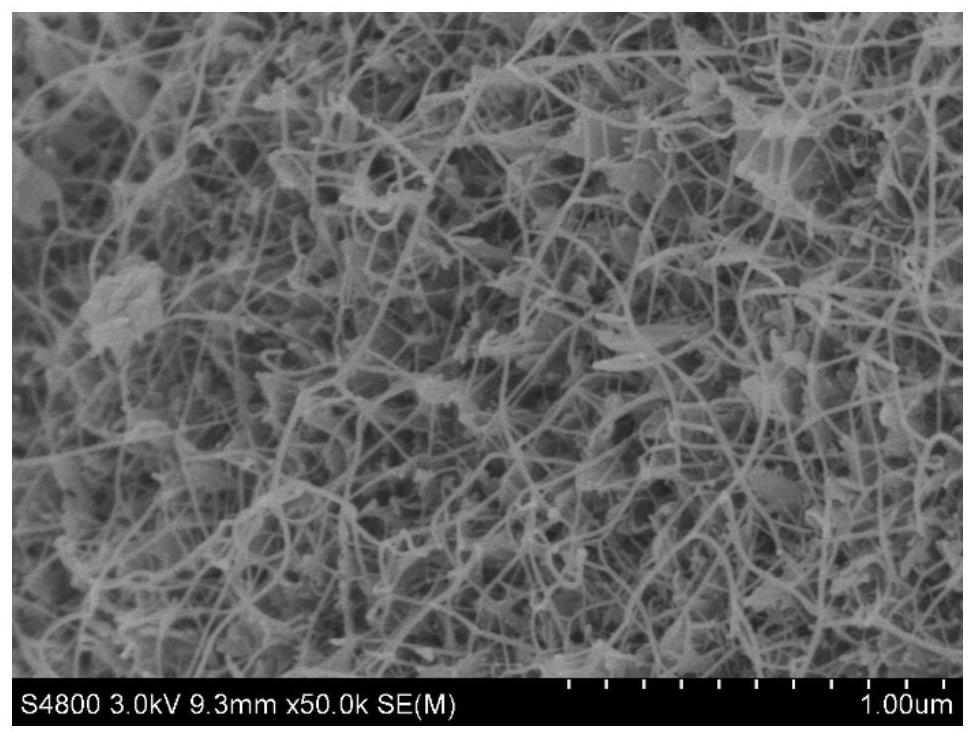

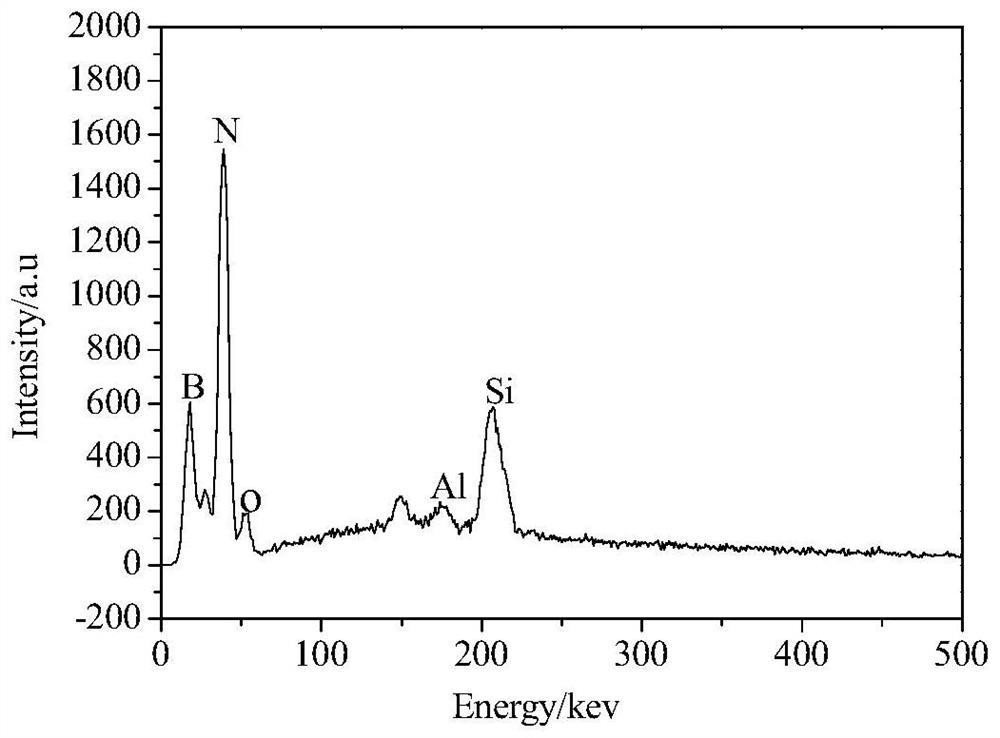

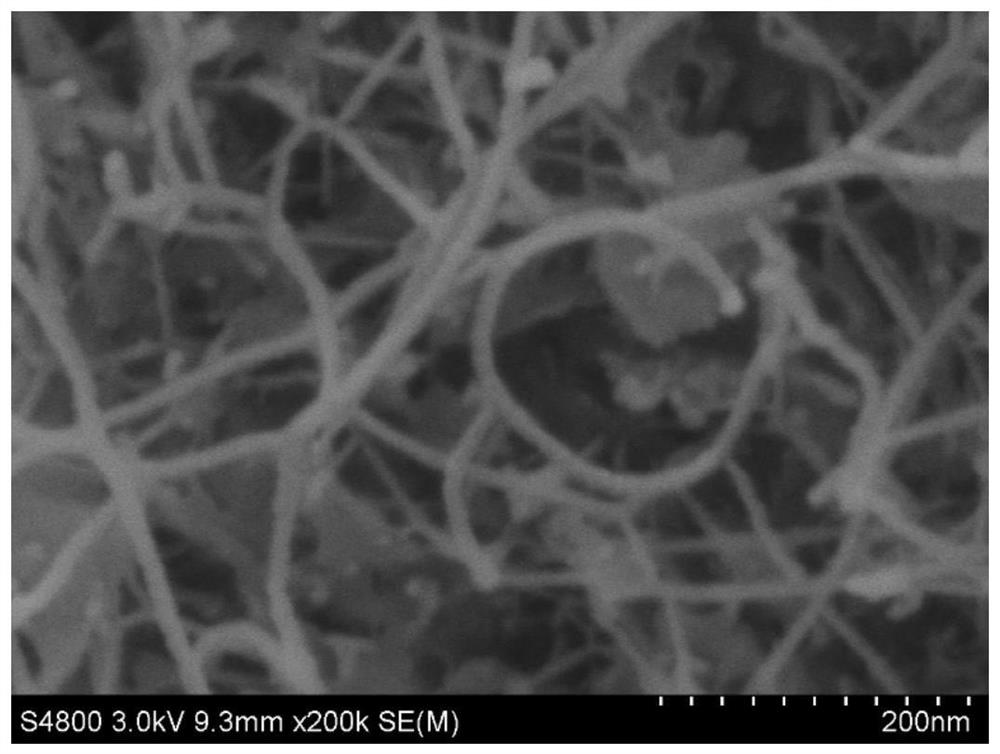

[0033] Step (2), the solid powder obtained in step (1) is placed in Al 2 o 3 In the porcelain boat, the porcelain boat was placed in a tubular atmosphere protection annealing furnace, and the temperature was raised from room temperature under the protection of 100mL / min argon gas at a rate of 10°C / min. When the temperature rose to 300°C, the argon valve was closed, and the Inject high-purity ammonia gas with a flow rate of 50mL / min. When the temperature further rises to 1300°C, keep warm for 8 hours, then stop feeding ammonia gas, and then cool down to room temperature naturally under a protective atmosphere, and a beige substance is obtaine...

Embodiment 2

[0040] Change the reaction temperature of step (2) in Example 1 to 1250°C, and the other operations are the same as in Example 1. A large amount of beige substance grows in the porcelain boat, and the SEM photo shows that its morphology and structure are the same as those in Example 1. same, only slightly smaller in number.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com