Installation method of combined joint with steel structure

A technology of combining joints and installation methods, which is applied in the direction of building construction, construction, and building material processing, can solve the problems of high machining accuracy requirements for truss lengths, difficult elimination of accumulated construction errors, and affecting the stability of steel pipe structures, etc., to achieve Improve the section flexural modulus, reduce safety hazards, and reduce the effect of processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

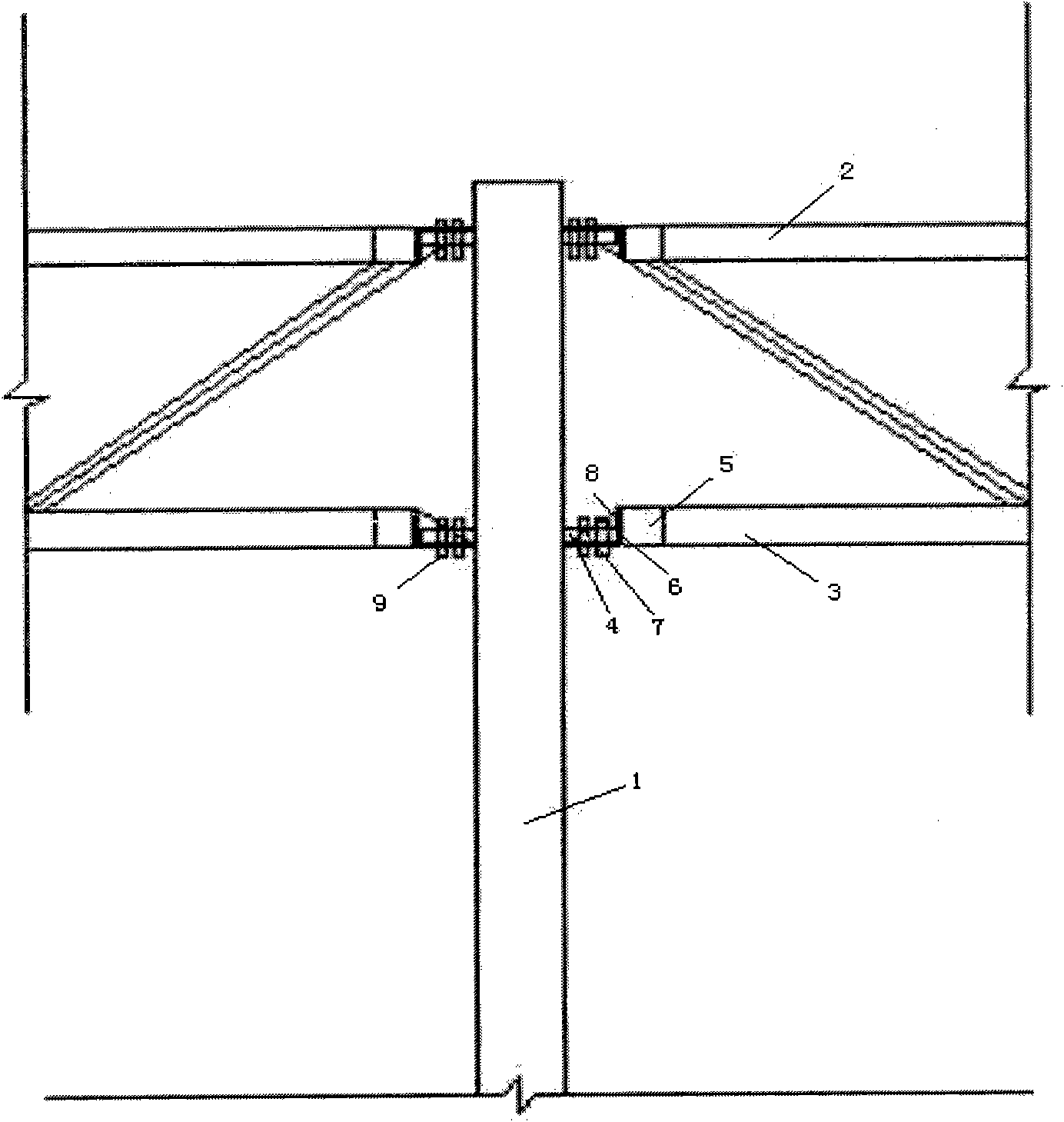

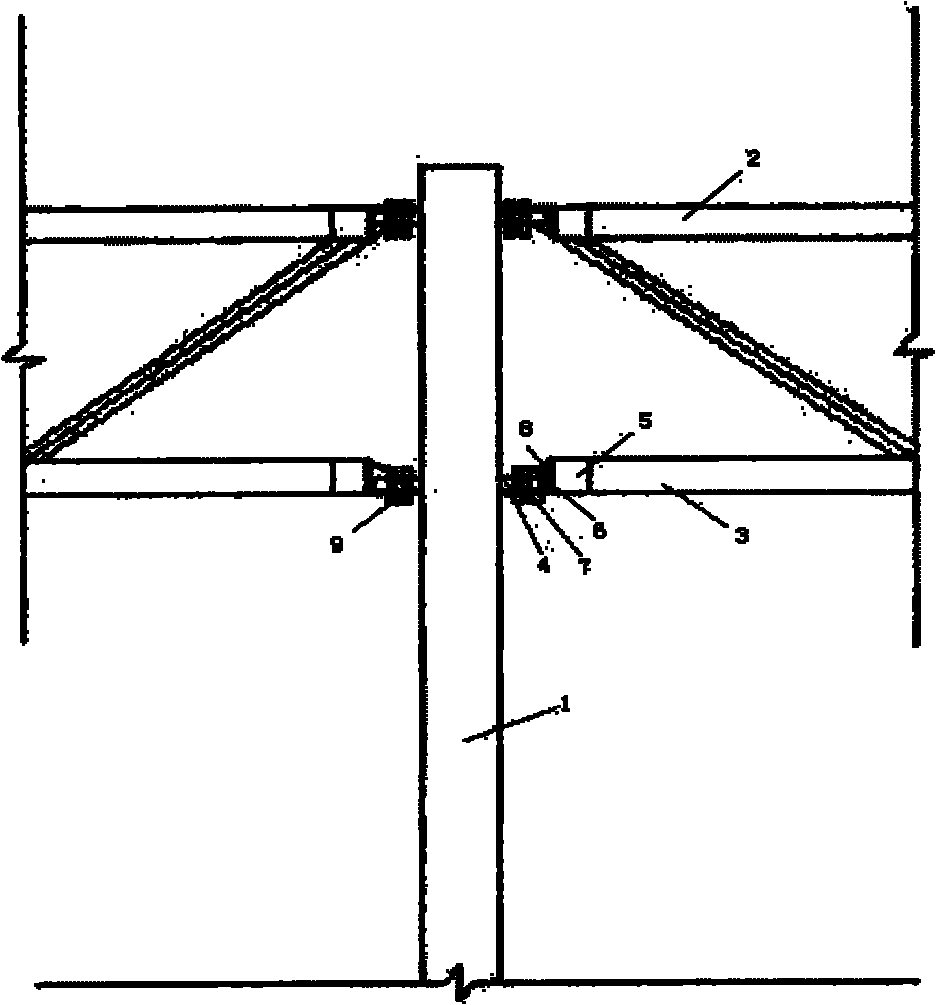

[0010] The specific implementation of the present invention will be described in further detail below with reference to the drawings.

[0011] The installation method of a steel structure combined node provided by the present invention can be carried out according to the following steps during specific operation:

[0012] 1. Construction preparation

[0013] According to the construction standard, inspect the quality of the raw steel used, that is, cold-formed square and rectangular steel, to ensure the safety of the raw material. At the same time, check that the machinery to be used in the construction process is intact, clean up the construction site, and minimize potential safety hazards. Column 1 is buried, and the diameter of steel column 1 is 180mm, ready for construction.

[0014] 2. Component production

[0015] Make channel steel 4, inner partition plate 5, head plate 6, connecting plate 7 and vertical stiffener 8 according to size requirements, and make bolt holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com